Mobile:+86-311-808-126-83

Email:info@ydcastings.com

French

Exploring the Art and Technology of Die Casting Manufacturing Techniques and Applications

Understanding Die Cast Dies and Their Importance in Manufacturing

Die casting is a manufacturing process that has gained widespread popularity due to its efficiency and ability to produce complex shapes with high precision. Central to this process are die cast dies, which are specialized tools used to create the molds for various metal parts. They play a crucial role in the efficiency and quality of the die casting process.

Die cast dies are typically made from heat-resistant steel or aluminum and are engineered to withstand the high pressures and temperatures involved in die casting. The primary purpose of a die is to shape molten metal into the desired form as it cools and solidifies. This process is not only essential for manufacturing a wide array of components but also enables the production of parts with superior surface finishes and dimensional accuracy.

There are two primary types of die casting dies single cavity and multi-cavity dies. Single cavity dies are designed to produce one part per cycle, making them ideal for low-volume production runs. In contrast, multi-cavity dies can produce multiple parts simultaneously, significantly enhancing productivity and reducing manufacturing costs for high-volume production. The choice between these types typically depends on the production requirements and the geometric complexity of the parts being manufactured.

The design of die cast dies is a critical factor that influences the overall success of the die casting process. Factors such as cooling channels, ejector systems, and venting systems must be carefully considered to optimize performance. Effective cooling systems are crucial as they regulate the temperature of the die, ensuring that the molten metal solidifies at the right pace, which helps in achieving the desired mechanical properties of the final product. Ejector systems help in removing the finished parts from the die without causing damage. Meanwhile, venting systems allow trapped air to escape, which is essential in preventing defects in the castings.

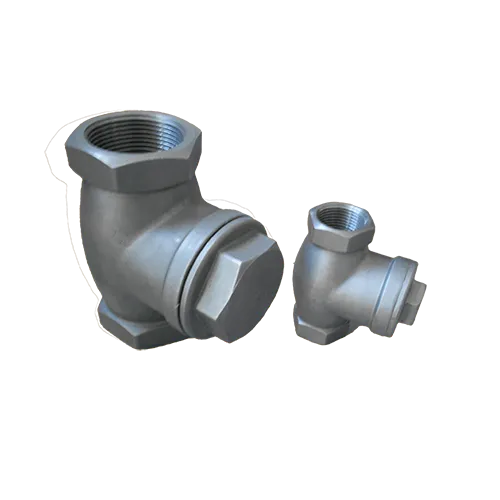

die cast dies

The manufacturing of die cast dies involves a series of intricate processes, including machining, heat treatment, and surface finishing

. Advanced technology, including computer-aided design (CAD) software and computer numerical control (CNC) machining, is often employed to ensure precision. The heat treatment process enhances the durability and lifespan of the dies, while surface finishing improves the quality of the parts produced by minimizing surface imperfections.In recent years, advancements in materials science and manufacturing techniques have led to the development of more robust and efficient die cast dies. New alloys and coatings enhance the wear resistance and thermal conductivity of the dies, which can significantly increase their operational lifespan. Additionally, innovations in 3D printing technology are being explored to create complex die geometries that were previously challenging or impossible to achieve using traditional manufacturing methods.

The impact of die cast dies on various industries cannot be overstated. From automotive components to consumer electronics, die casting delivers parts that meet strict performance and aesthetic standards. The ability to produce lightweight yet strong components is particularly beneficial in industries striving for energy efficiency and sustainability.

In summary, die cast dies are indispensable tools in the die casting process, and their design and manufacture significantly influence the quality and efficiency of production. As technology continues to advance, the potential for die casting and its applications across different sectors will undoubtedly expand, making it an essential area of focus in modern manufacturing practices.