Mobile:+86-311-808-126-83

Email:info@ydcastings.com

English

Welding Techniques for End Cap Stainless Steel Fittings

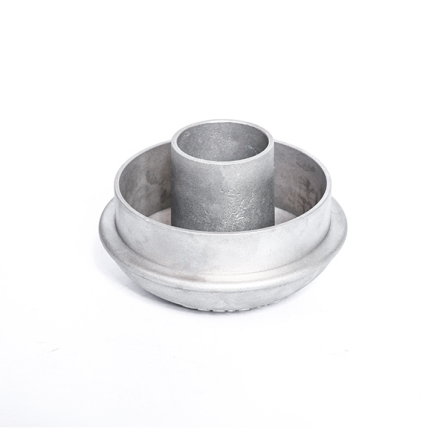

Welding end cap stainless steel fittings requires precision and the right techniques to ensure strong, durable, and corrosion-resistant joints. These fittings, used to seal the ends of stainless steel pipes, are vital in industries like plumbing, food processing, and chemical handling. Hebei Yuanda Trade Co., Ltd. (YD), founded in 2006, specializes in customized metal castings, including high-quality end cap stainless steel and end cap aluminium fittings. With their expertise in metal processing, YD understands the unique challenges of welding these components, providing insights into techniques that guarantee reliable results.

Key Welding Techniques for End Cap Stainless Steel Fittings

- Tungsten Inert Gas (TIG) Welding: TIG welding is a top choice for end cap stainless steel fittings due to its precision. It uses a non-consumable tungsten electrode to create the arc, with an inert gas (like argon) shielding the weld pool from contamination. This technique produces clean, high-quality welds with minimal spatter, ideal for stainless steel’s corrosion-resistant properties. It works well for thin-walled end cap stainless steel fittings, ensuring the material doesn’t warp under heat.

- Metal Inert Gas (MIG) Welding: MIG welding is faster than TIG, making it suitable for larger end cap stainless steelfittings or high-volume production. It uses a consumable wire electrode and inert gas shielding, depositing filler material to form the weld. While it may not be as precise as TIG, MIG welding still delivers strong joints when adjusted correctly, making it a practical option for industrial applications.

- Resistance Welding: This technique uses electrical resistance to generate heat at the joint between the end cap stainless steeland the pipe. It’s efficient for joining thin materials and works well for automated processes, ensuring consistent welds. Resistance welding is often used for end caps for aluminum tubing too, though parameters differ from stainless steel due to aluminum’s lower melting point.

Welding Considerations for End Cap Aluminium vs Stainless Steel

- Heat Sensitivity: End cap aluminiumhas a lower melting point (around 660°C) compared to stainless steel (around 1400°C). This means aluminum requires lower heat input during welding to avoid distortion or burn-through. For end cap stainless steel, higher heat is needed, but overheating can cause carbide precipitation, reducing corrosion resistance. Adjusting the welding current and travel speed is crucial for both materials.

- Oxidation Prevention: Aluminum forms a tough oxide layer that must be removed before welding to ensure proper fusion. This can be done with a wire brush or by using a specialized filler material with deoxidizers. End cap stainless steelalso oxidizes, but the chromium in the alloy forms a protective layer that self-heals. Inert gas shielding is more critical for aluminum to prevent re-oxidation during welding.

- Filler Material Selection: For end cap stainless steel, filler wires matching the base metal’s alloy (like 304 or 316) are used to maintain corrosion resistance. For end cap aluminium, filler wires (such as 4043 or 5356) are chosen to match the aluminum alloy, ensuring strength and ductility in the weld.

Pre-Welding Preparation for End Cap Stainless Steel Fittings

- Cleaning the Surface: End cap stainless steelfittings must be free of oil, grease, dirt, or oxide layers before welding. Use a stainless steel brush or a solvent (like acetone) to clean the joint area. For end cap aluminium, a wire brush (non-steel to avoid contamination) or chemical cleaner removes the oxide layer, ensuring proper weld penetration.

- Fit-Up and Alignment: The end cap stainless steelmust align perfectly with the pipe to ensure a uniform weld. Gaps between the cap and pipe can lead to weak joints or excessive filler material usage. Clamps or fixtures help hold the components in place during welding, preventing movement that could compromise the weld’s integrity.

- Choosing the Right Equipment: Using a welding machine with adjustable settings (current, voltage, gas flow) is essential. For TIG welding end cap stainless steel, a machine with high-frequency start and foot pedal control allows precise heat adjustment. For end caps for aluminum tubing, a machine with AC output is needed to break through aluminum’s oxide layer.

Common Welding Defects and Solutions for End Cap Stainless Steel

|

Defect |

Causes |

Solutions for End Cap Stainless Steel |

Solutions for End Cap Aluminium |

|

Porosity |

Contamination or inadequate gas shielding |

Clean surfaces, increase gas flow |

Remove oxide layer, use deoxidizing filler |

|

Distortion |

Excessive heat input |

Reduce current, speed up travel, use clamps |

Lower heat, use tack welds to secure components |

|

Lack of Fusion |

Insufficient heat or poor joint fit-up |

Increase heat, ensure tight fit between cap and pipe |

Adjust heat, clean oxide layer thoroughly |

End Cap Stainless Steel FAQS

Can I Use the Same Welding Technique for End Cap Stainless Steel and End Cap Aluminium?

While some techniques (like TIG or MIG) work for both, parameters differ significantly. End cap stainless steel requires higher heat and often DC current, while end cap aluminium needs lower heat and AC current to break the oxide layer. Always adjust settings based on the material.

What Filler Material Is Best for Welding End Cap Stainless Steel Fittings?

For 304 end cap stainless steel , use a 308 filler wire. For 316 stainless steel, a 316 filler is ideal. These fillers match the base metal’s composition, ensuring corrosion resistance and strength in the weld.

How Do I Prevent Warping When Welding Thin End Cap Stainless Steel?

Use TIG welding with low heat input, keep the arc short, and move quickly along the joint. Tack welding the end cap stainless steel to the pipe at intervals before final welding also helps distribute heat evenly, reducing warping.

Is Passivation Necessary for All End Cap Stainless Steel Welds?

It’s highly recommended, especially for fittings used in corrosive environments (like marine or chemical applications). Passivation removes impurities from the weld, restoring the chromium oxide layer that protects end cap stainless steel from rust.

What’s the Best Way to Weld End Caps for Aluminum Tubing?

TIG welding with AC current is best for end caps for aluminum tubing. Clean the oxide layer first, use a filler wire designed for aluminum (like 4043), and ensure proper gas shielding to prevent oxidation during welding. This ensures strong, ductile welds.

-

Materials Used in Manufacturing Cap End Pipe FittingsNewsNov.24,2025

-

Material Properties of CF8M CastingNewsNov.24,2025

-

How to Inspect Pump Cap Ends for DamageNewsNov.21,2025

-

Backward Curved Impeller – Efficient Airflow Solutions for Industry | YD CastingsNewsNov.21,2025

-

Automobile Water Pump - Efficient, Quiet, Durable & ElectricNewsNov.21,2025

-

Impeller for Pumps – High-Efficiency, Durable, OEM-ReadyNewsNov.21,2025