Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Spanish

Feb . 19, 2025 06:53

Back to list

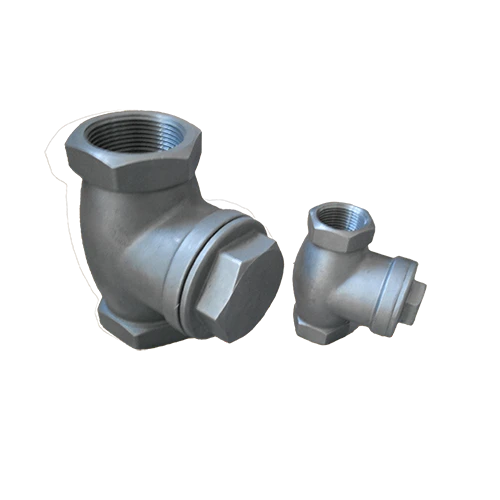

valve body castings

Valve castings stand as a vital component within the manufacturing and mechanical systems industries. They are pivotal in various applications ranging from automotive engines to industrial piping systems. The process of creating valve castings involves transforming molten metal into a meticulously designed and precision-engineered product. This article aims to convey professional insights into the intricacies of valve castings, shed light on their production nuances, showcase their applications, and emphasize their undeniable importance in industrial sectors.

The applications of valve castings span across multiple industries. In the automotive sector, they are crucial for engine safety and efficiency, managing fluid control under various operating conditions. Industrial sectors utilize them in pipeline systems to control the flow of gases and liquids, essential for operational safety and efficiency. The specialized design of each casting ensures that it performs optimally, even under high-stress conditions, reiterating its authoritative presence in essential infrastructure. Brand reputation also hinges on producing reliable valve castings. Companies investing in cutting-edge technology for precision casting, ethical sourcing of materials, and comprehensive testing foster trust with their clientele. Clients, ranging from large corporations to government bodies, rely heavily on the dependability of these products, influencing their procurement decisions. Thus, manufacturers prioritize building a trustworthy brand image through consistent quality and reliability. Valve castings underscore significant industrial importance and reflect the sophisticated interplay of material science, engineering prowess, and stringent quality standards. The process demands a blend of experience, expertise, authoritative industry knowledge, and unwavering commitment to quality. These components coalesce to deliver products that not only meet but exceed the demanding expectations of various industries reliant on their functionality. The evolution of valve casting technologies continues to advance, promoting innovation that further enhances efficiency and reduces environmental impact. Valves that ensure the seamless flow of operations in numerous sectors echo the importance of this specialized casting discipline. As industries adapt to modern challenges, the role of reliable and expertly crafted valve castings remains more relevant than ever, solidifying the industry's foundation of experience, expertise, authoritativeness, and trustworthiness.

The applications of valve castings span across multiple industries. In the automotive sector, they are crucial for engine safety and efficiency, managing fluid control under various operating conditions. Industrial sectors utilize them in pipeline systems to control the flow of gases and liquids, essential for operational safety and efficiency. The specialized design of each casting ensures that it performs optimally, even under high-stress conditions, reiterating its authoritative presence in essential infrastructure. Brand reputation also hinges on producing reliable valve castings. Companies investing in cutting-edge technology for precision casting, ethical sourcing of materials, and comprehensive testing foster trust with their clientele. Clients, ranging from large corporations to government bodies, rely heavily on the dependability of these products, influencing their procurement decisions. Thus, manufacturers prioritize building a trustworthy brand image through consistent quality and reliability. Valve castings underscore significant industrial importance and reflect the sophisticated interplay of material science, engineering prowess, and stringent quality standards. The process demands a blend of experience, expertise, authoritative industry knowledge, and unwavering commitment to quality. These components coalesce to deliver products that not only meet but exceed the demanding expectations of various industries reliant on their functionality. The evolution of valve casting technologies continues to advance, promoting innovation that further enhances efficiency and reduces environmental impact. Valves that ensure the seamless flow of operations in numerous sectors echo the importance of this specialized casting discipline. As industries adapt to modern challenges, the role of reliable and expertly crafted valve castings remains more relevant than ever, solidifying the industry's foundation of experience, expertise, authoritativeness, and trustworthiness.

Next:

Related PRODUCTS