Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Spanish

precision metal casting

Precision Metal Casting The Key to High-Quality Metal Components

In the realm of manufacturing, precision metal casting stands out as a pivotal process for creating intricate metal components with exceptional accuracy and quality. This technique is widely employed across various industries, including automotive, aerospace, and electronics, where the demand for high-performance materials is paramount. This article delves into the intricacies of precision metal casting, exploring its processes, applications, and advantages.

Understanding Precision Metal Casting

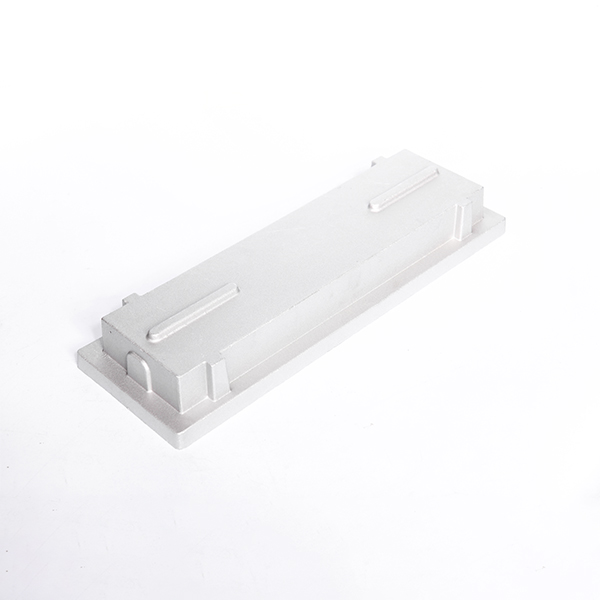

Precision metal casting is a manufacturing process that involves pouring molten metal into a mold that is designed to produce a specific shape. The molds are often made from sand, metal, or ceramic, and the choice of material depends on the desired accuracy, surface finish, and production volume. The term precision refers to the high level of detail and exactitude that can be achieved, often with tolerances as tight as ±0.005 inches.

Different casting methods are employed, including investment casting, die casting, and sand casting. Among these methods, investment casting is particularly notable for its ability to replicate complex geometries with smooth surface finishes. It involves creating a wax pattern that is subsequently coated in a ceramic shell, which is then heated to remove the wax and form a mold. This process allows for the production of highly detailed components, making it ideal for industries that require components with intricate features.

Applications in Various Industries

Precision metal casting has found its application in a wide array of sectors. In the automotive industry, for instance, it is crucial for manufacturing engine components, transmission cases, and exhaust manifolds, all of which require excellent mechanical properties and precise fit. These castings must endure high levels of stress and heat, necessitating the use of high-quality alloys and meticulous engineering.

In aerospace, where weight reduction and structural integrity are critical, precision castings are essential for components such as turbine blades and structural parts. These applications demand not only precision but also the use of advanced materials that can withstand extreme conditions, demonstrating the versatility of precision metal casting.

precision metal casting

Electronics manufacturers also rely on this technique to produce heat sinks and housing for delicate components

. The ability to create thin-walled, complex geometries helps improve the efficiency and performance of electronic devices, showcasing the breadth of industries that benefit from precision metal casting.Advantages of Precision Metal Casting

The benefits of precision metal casting are manifold. First and foremost, the level of detail achievable is unparalleled compared to other manufacturing processes. This high level of precision leads to fewer machining operations, reducing both time and costs. Furthermore, the process allows for the production of complex shapes that would be challenging and costly to achieve through machining or fabrication methods.

Another significant advantage is material efficiency. Precision metal casting minimizes waste by utilizing the exact amount of metal needed for the component, which is particularly important in industries where material costs are high. Additionally, the ability to cast multiple components simultaneously can significantly enhance production efficiency.

Finally, precision metal casting contributes to sustainability in manufacturing. The process can utilize recycled metals, reducing the environmental impact and promoting a circular economy. As industries continue to push for greener practices, precision casting offers a viable solution to meet these demands.

Conclusion

In summary, precision metal casting is a crucial manufacturing process that delivers high-quality, accurate, and efficient components across various industries. As technology advances and industries evolve, the importance of precision metal casting in designing innovative solutions will only continue to grow. With its ability to produce complex geometries, reduce waste, and improve overall efficiency, precision metal casting stands as a cornerstone of modern manufacturing. Emphasizing quality and precision, it ensures that businesses can meet the demands of a rapidly changing market while maintaining the highest standards of excellence.