Mobile:+86-311-808-126-83

Email:info@ydcastings.com

English

Precision Stainless Steel Casting | Custom Metal Parts

Advancing Industrial Reliability with stainless steel casting Solutions

In the demanding landscape of modern industrial applications, the integrity and performance of critical components are paramount. Stainless steel casting stands as a cornerstone technology, delivering unparalleled corrosion resistance, high strength-to-weight ratios, and dimensional stability. This robust manufacturing process is indispensable for sectors where operational reliability cannot be compromised, from extreme temperature environments to highly corrosive chemical processes.

Recent industry trends indicate a growing demand for custom-engineered castings that offer enhanced performance and longer service life, particularly in energy, maritime, and chemical processing. This shift is driven by stricter environmental regulations, the need for increased operational efficiency, and a global emphasis on sustainable manufacturing practices. Innovations in alloy development and advanced simulation techniques are further pushing the boundaries of what is achievable with stainless steel casting, allowing for increasingly complex geometries and superior material properties.

The Precision of Stainless Steel Casting: A Detailed Process Flow

The manufacturing of high-quality stainless steel casting involves a meticulously controlled, multi-stage process designed to achieve specific metallurgical properties and intricate geometries. This process often leverages investment casting (lost-wax method) for its superior precision and surface finish, although sand casting and shell molding are also utilized depending on part complexity and volume.

Process Steps:

- 1. Pattern Creation: An accurate wax pattern of the desired component is created, either through injection molding for high volume or additive manufacturing for prototypes. These patterns are assembled onto a sprue to form a tree.

- 2. Slurry & Stucco Application: The wax tree is dipped into a ceramic slurry and then coated with refractory stucco. This process is repeated multiple times, building up successive layers to form a robust ceramic shell around the wax pattern.

- 3. Dewaxing: The ceramic shell, with the wax pattern inside, is heated in an autoclave. The wax melts and drains out, leaving a hollow ceramic mold. This "lost wax" technique is crucial for achieving fine details.

- 4. Shell Firing: The ceramic shell is fired at high temperatures (typically 900-1100°C) to burn out residual wax, strengthen the ceramic, and preheat it for metal pouring.

- 5. Metal Melting & Pouring: High-grade stainless steel alloys (e.g., SS304, SS316, 17-4PH) are melted in induction furnaces, with precise control over chemical composition. The molten metal is then poured into the hot ceramic molds.

- 6. Cooling & Solidification: The molten metal cools within the mold, solidifying into the final casting. Controlled cooling rates are essential to achieve desired microstructure and mechanical properties.

- 7. Shakeout & Cut-off: Once cooled, the ceramic shell is mechanically removed (shakeout), revealing the cast components still attached to the sprue. Individual castings are then cut off.

- 8. Finishing & Heat Treatment: Castings undergo fettling (grinding, sanding) to remove gates and risers. Depending on the alloy and application, heat treatments (annealing, solution treatment, precipitation hardening) are performed to optimize mechanical properties, stress relief, and corrosion resistance.

- 9. Machining & Testing: Components may require secondary operations like CNC machining to achieve tighter tolerances. Rigorous testing, including dimensional inspection, non-destructive testing (NDT - X-ray, liquid penetrant, magnetic particle), mechanical property tests (tensile, hardness), and chemical analysis, ensures compliance with standards such as ISO 9001, ASTM A743/A744, and ANSI B16.5.

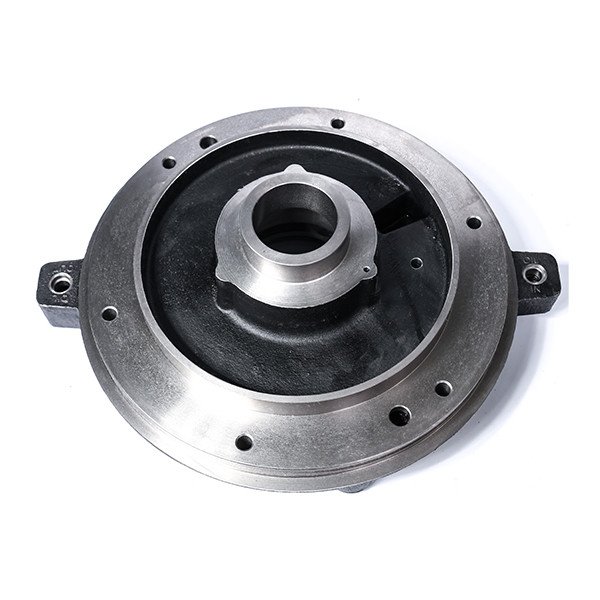

The service life of these components, such as a Cooling Flange Lower or Bearing Housing Lower, can extend decades in target industries like petrochemical, metallurgy, and water supply & drainage, thanks to superior corrosion resistance and material integrity. This longevity translates directly into energy saving through reduced maintenance and replacement costs, a critical advantage for heavy industrial operations.

Technical Specifications and Performance Parameters

The selection and application of stainless steel casting are predicated on precise technical specifications that ensure optimal performance under operational stresses. These castings are engineered to meet stringent mechanical, chemical, and dimensional requirements.

Typical Stainless Steel Casting Product Specifications:

| Parameter | Cooling Flange Lower (Example) | Bearing Housing Lower (Example) |

|---|---|---|

| Material Grade | ASTM A743 Gr. CF8M (316 SS) | ASTM A743 Gr. CF3 (304L SS) |

| Tensile Strength (min.) | 485 MPa (70 ksi) | 415 MPa (60 ksi) |

| Yield Strength (min.) | 170 MPa (25 ksi) | 205 MPa (30 ksi) |

| Elongation (min.) | 30% | 35% |

| Hardness (max.) | 200 HB | 190 HB |

| Dimensional Tolerance | ISO 8062 CT5-CT7 (after machining) | ISO 8062 CT5-CT6 (after machining) |

| Surface Finish | Ra 3.2 - 6.3 µm (as-cast), Ra 0.8 - 1.6 µm (machined) | Ra 3.2 - 6.3 µm (as-cast), Ra 0.8 - 1.6 µm (machined) |

| Weight Range | 0.5 kg - 50 kg | 0.1 kg - 30 kg |

| Casting Process | Investment Casting / Sand Casting | Investment Casting |

Beyond primary casting, many components require secondary processes like CNC machining to achieve the ultimate precision required for critical interfaces and tight fits. The combination of high-integrity casting and precision machining ensures components like these cooling flanges and bearing housings perform flawlessly in their intended assemblies.

Application Scenarios and Technical Advantages

The intrinsic properties of stainless steel make stainless steel casting an ideal choice for components operating in challenging environments. Its technical advantages translate into superior performance and economic benefits across a multitude of industries.

Key Application Industries:

- Petrochemical & Oil & Gas: Valves, pump housings, flanges, and fittings exposed to corrosive chemicals, high pressures, and extreme temperatures. Components like the Cooling Flange Lower ensure integrity in heat exchangers and piping systems.

- Metallurgy & Heavy Machinery: Bearing housings, levers, and specialized machine parts requiring high wear resistance and structural integrity in harsh, high-load conditions. The Bearing Housing Lower example demonstrates a need for robust material.

- Water Supply & Drainage: Impellers, pump components, and pipe connectors that must resist corrosion from water, wastewater, and various dissolved chemicals.

- Food & Pharmaceutical: Hygienic processing equipment where cleanliness and resistance to sterilization agents are critical. Stainless steel's non-reactive surface is paramount here.

- Marine & Offshore: Components for ships, offshore platforms, and subsea equipment that must withstand saltwater corrosion.

Technical Advantages:

- Superior Corrosion Resistance: Chromium content forms a passive layer, protecting against rust, acids, chlorides, and other aggressive media. This extends component life dramatically compared to plain carbon steel.

- High Strength & Ductility: Offers excellent mechanical properties, including high tensile and yield strengths, while retaining good ductility and impact resistance across a wide temperature range.

- Temperature Stability: Maintains mechanical properties at both elevated and cryogenic temperatures, making it suitable for a broad spectrum of thermal applications.

- Design Flexibility: The casting process allows for complex geometries and intricate internal features that would be difficult or costly to achieve with other manufacturing methods like forging or fabrication.

- Cost-Effectiveness (Long-Term): While initial investment might be higher than some alternatives, the extended service life, reduced maintenance, and avoidance of premature failure result in significant long-term energy saving and operational cost reductions.

Comparison with Other Metal Casting Methods:

| Feature | Stainless Steel Casting (Investment) | Aluminum Die Casting | Green Sand Metal Casting |

|---|---|---|---|

| Typical Material | Stainless Steel (304, 316, 17-4PH) | Aluminum Alloys (A380, A360) | Gray Iron, Ductile Iron, Carbon Steel |

| Corrosion Resistance | Excellent (alloy dependent) | Good (can be anodized) | Poor to Moderate (requires coating) |

| Strength-to-Weight | High | Very High (lightweight) | Moderate (heavy) |

| Dimensional Accuracy | Very High (Investment Casting) | High (especially aluminum casting die) | Moderate (requires significant machining) |

| Surface Finish | Excellent (Ra 3.2-6.3 µm as-cast) | Very Good | Rough (Ra 12.5-25 µm as-cast) |

| Complexity of Parts | Very High | High (limited by draft angles) | Moderate |

| Tooling Cost | Moderate to High | High | Low to Moderate |

| Unit Cost (High Volume) | Moderate | Low | Very Low |

While aluminum die casting offers lightweight advantages and high-volume efficiency, and green sand metal casting is cost-effective for large, less precise components, neither can match the combined corrosion resistance, high-temperature performance, and precision offered by specialized stainless steel casting, especially for critical industrial applications. For specific components like a Cooling Flange Lower, where leak-proof integrity and prolonged resistance to chemical exposure are paramount, the choice of stainless steel is often non-negotiable. Similarly, a Bearing Housing Lower in harsh environments benefits immensely from the material's durability, preventing premature failure and reducing operational downtime.

Vendor Comparison and Customized Solutions

Selecting the right manufacturing partner for stainless steel casting is a strategic decision that impacts product quality, lead times, and overall project success. A proficient vendor offers not just manufacturing capabilities, but also comprehensive engineering support for customized solutions.

Key Considerations for Vendor Selection:

- Technical Expertise: Proven experience with various stainless steel alloys, intricate geometries, and industry-specific requirements.

- Quality Certifications: Adherence to international standards such as ISO 9001, ASTM, PED, and other relevant industry-specific certifications.

- Advanced Facilities: State-of-the-art casting, heat treatment, CNC machining, and inspection capabilities. The ability to perform precise CNC machining post-casting is crucial for achieving tight tolerances on critical surfaces.

- Customization & Engineering Support: Ability to provide Design for Manufacturability (DFM) feedback, material selection guidance, and rapid prototyping for bespoke components.

- Supply Chain Reliability: Consistent lead times, robust quality control, and excellent communication throughout the production process.

Customized solutions are critical for optimizing component performance in specific operational contexts. This often involves tailoring the alloy composition, designing unique geometries to fit existing systems, or integrating features that enhance functionality. For instance, a customized Cooling Flange Lower might incorporate specific port configurations or sealing surfaces to improve system efficiency and prevent leakage in a unique heat exchanger design. Similarly, a bespoke Bearing Housing Lower could be engineered with optimized internal passages for lubrication or specific mounting points for enhanced stability in a high-vibration assembly. Expert vendors leverage their technical acumen to transform complex requirements into precise, high-performance metal castings.

Real-World Application Case Studies & Expertise

Our extensive experience in delivering high-performance stainless steel casting solutions has garnered trust from leading enterprises globally. These case studies highlight our capability to address complex industrial challenges with precision-engineered components.

Case Study 1: Enhanced Lifespan for Petrochemical Pump Components

Challenge: A major petrochemical client faced frequent failures of pump impellers and housings due to aggressive chemical corrosion and abrasive wear in their refining units. Components made from standard carbon steel required replacement every 6-8 months, leading to significant downtime and maintenance costs.

Solution: We engineered and cast these critical components using ASTM A743 Gr. CD4MCu (a duplex stainless steel) via investment casting. This alloy offers superior resistance to pitting and crevice corrosion, combined with high strength.

Result: The new stainless steel casting components demonstrated a service life exceeding 3 years, a more than 400% improvement. This resulted in a 75% reduction in unplanned maintenance, substantial energy saving, and increased operational uptime for the client.

Case Study 2: Precision Bearing Housing for Heavy Machinery

Challenge: A manufacturer of large-scale industrial mixers required a Bearing Housing Lower component that could withstand continuous heavy loads, high operational temperatures, and resist corrosion from a range of processing agents. The original cast iron housings exhibited insufficient strength and localized corrosion.

Solution: Utilizing our expertise in precision metal castings, we developed a Bearing Housing Lower from ASTM A743 Gr. CF8 (304 SS) through investment casting, followed by precision CNC machining for critical bearing surfaces. The design optimized wall thickness and internal structure for stress distribution.

Result: The client reported a significant reduction in bearing failures and increased overall equipment reliability. The enhanced material properties and dimensional accuracy of our stainless steel casting extended the mixer's operational lifespan and reduced the frequency of costly component replacements, demonstrating our commitment to client success and superior engineering.

Our partnerships with leading clients across petrochemical, power generation, and general heavy industry sectors, coupled with decades of service, underscore our authoritative position in providing reliable and high-performance aluminium metal casting and stainless steel solutions.

Trustworthiness: FAQ, Lead Time, Warranty, and Support

Building lasting relationships with our B2B partners is founded on transparency, reliability, and robust support. We address common inquiries, provide clear operational details, and stand behind the quality of our stainless steel casting products.

Frequently Asked Questions (FAQ):

-

Q: What stainless steel grades do you typically cast?

A: We commonly cast a wide range of austenitic (304, 304L, 316, 316L), martensitic (410, 420, 17-4PH), duplex (2205, 2507), and super duplex stainless steels, tailored to specific application requirements. -

Q: Can you accommodate complex geometries?

A: Yes, our advanced investment casting capabilities allow for the production of highly complex and intricate designs with excellent dimensional accuracy and surface finish. We also offer expertise in aluminum casting die for components suited to that process. -

Q: What are your quality control measures?

A: Our processes are ISO 9001 certified. We employ rigorous quality control at every stage, including spectral analysis of raw materials, in-process dimensional checks, NDT (RT, UT, PT, MT) post-casting, and comprehensive mechanical property testing. -

Q: Do you offer post-casting machining?

A: Absolutely. We have extensive in-house CNC machining capabilities to deliver finished components with precise tolerances and surface finishes, reducing the need for multiple vendors.

Lead Time & Fulfillment:

Standard lead times for new stainless steel casting projects typically range from 8-12 weeks for tooling development and initial sample production, followed by 4-6 weeks for subsequent production runs, depending on complexity and order volume. Expedited services may be available for urgent requirements. We work closely with clients to establish realistic timelines and maintain consistent communication throughout the order lifecycle.

Warranty Commitments:

We provide a comprehensive warranty against manufacturing defects and material non-conformance, ensuring that all our metal castings meet or exceed agreed-upon specifications and industry standards. Specific warranty terms are detailed in our sales agreements, reflecting our commitment to quality and customer satisfaction.

Customer Support:

Our dedicated technical support team is available to assist with inquiries, technical challenges, and after-sales service. We offer engineering consultation, material selection advice, and problem-solving support to ensure optimal performance and longevity of our products. Contact us via phone, email, or through our website for prompt and professional assistance.

Authoritativeness and Certifications

Our commitment to excellence in stainless steel casting is reinforced by robust certifications, rigorous adherence to international standards, and long-standing relationships with industry leaders. We maintain a transparent operational framework that invites scrutiny and builds trust.

Certifications and Compliance:

- ISO 9001:2015 Certified: Demonstrating a consistent commitment to quality management systems that ensure product and service excellence.

- ASTM and ANSI Standards: All materials and processes conform to relevant American Society for Testing and Materials (ASTM) and American National Standards Institute (ANSI) specifications (e.g., ASTM A743, ASTM A351, ANSI B16.5).

- PED (Pressure Equipment Directive) Compliance: Where applicable, components designed for pressure-related applications meet European Pressure Equipment Directive requirements.

- PPAP (Production Part Approval Process): We provide full PPAP documentation upon request, ensuring comprehensive validation of our manufacturing process and product quality.

Our operational tenure, spanning over two decades in high-precision metal castings, reflects a deep institutional knowledge and a track record of reliability. We are proud partners to a diverse portfolio of clients, including top-tier companies in energy infrastructure, chemical manufacturing, and heavy industrial machinery, who rely on our consistent quality and technical acumen.

Conclusion

The strategic value of stainless steel casting in modern industrial applications cannot be overstated. Its unique combination of corrosion resistance, mechanical strength, and design flexibility positions it as an indispensable technology for critical components in demanding environments. From petrochemical facilities to water treatment plants, the longevity, reliability, and cost-efficiency offered by precision-engineered stainless steel castings directly contribute to operational excellence and sustainable industrial practices. By partnering with an experienced and certified vendor, businesses can leverage customized solutions, optimize performance, and ensure the long-term integrity of their vital infrastructure.

References:

- ASTM International. "A743/A743M - 20 Standard Specification for Castings, Iron-Chromium-Nickel, Corrosion-Resistant, for General Application."

- ASM Handbook, Volume 15: Casting. ASM International, 2008.

- International Organization for Standardization. "ISO 8062-3:2007 Geometrical product specifications (GPS) -- Dimensional and geometrical tolerances for moulded parts -- Part 3: General dimensional and geometrical tolerances and machining allowances for castings."

- Kattamis, T. Z. "Investment Casting of Steels and Superalloys." Materials Science and Technology, 2011.

- European Committee for Standardization. "EN 13445-4:2014 Unfired pressure vessels — Part 4: Fabrication."

-

Materials Used in Manufacturing Cap End Pipe FittingsNewsNov.24,2025

-

Material Properties of CF8M CastingNewsNov.24,2025

-

How to Inspect Pump Cap Ends for DamageNewsNov.21,2025

-

Backward Curved Impeller – Efficient Airflow Solutions for Industry | YD CastingsNewsNov.21,2025

-

Automobile Water Pump - Efficient, Quiet, Durable & ElectricNewsNov.21,2025

-

Impeller for Pumps – High-Efficiency, Durable, OEM-ReadyNewsNov.21,2025