Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Understanding the Functionality of Marine Engine Exhaust Manifolds for Enhanced Performance

Understanding Exhaust Manifolds in Marine Engines

In the world of marine engineering, the exhaust manifold is a vital component that plays a significant role in the efficient functioning of marine engines. Marine engines, whether they are diesel or gasoline-powered, require a well-designed exhaust system to manage the byproducts of combustion effectively. The exhaust manifold serves as the connecting piece between the engine’s cylinder head and the exhaust system, ultimately leading to the discharge of exhaust gases into the atmosphere or the water, depending on the engine design.

Function of the Exhaust Manifold

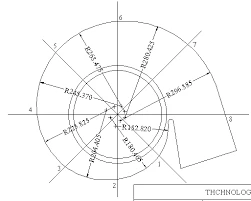

The primary function of the exhaust manifold is to collect exhaust gases from the engine’s cylinders and direct them to the exhaust system. The manifold, typically made from cast iron or stainless steel, is designed to withstand high temperatures and corrosive elements present in the exhaust gases. The manifold’s design is critical; it must facilitate efficient gas flow to reduce back pressure, which can adversely affect engine performance.

Types of Exhaust Manifolds

There are several types of exhaust manifolds used in marine engines, including wet and dry manifolds

.1. Wet Exhaust Manifold This type is commonly used in small to medium marine engines and is designed to cool the exhaust gases by introducing a water-cooling system. This not only helps in reducing the temperature of the exhaust gases but also minimizes the risk of overheating the manifold itself. The water is introduced into the manifold, forming a mixture of water and exhaust gas, which is then expelled through the exhaust outlet.

2. Dry Exhaust Manifold Typically found in larger, high-performance marine engines, the dry exhaust manifold directs the exhaust gases without incorporating a water-cooling system. This type is used in applications where maximum efficiency and performance are required, as it allows for higher exhaust gas temperatures, which can improve turbocharger efficiency in turbocharged engines.

exhaust manifold marine engine

Design Considerations

The design of an exhaust manifold must take several factors into account, including material selection, heat dissipation, and structural integrity. Cast iron remains a popular choice due to its durability and ability to withstand high temperatures. However, stainless steel manifolds are increasingly favored in high-performance and corrosive environments because they offer superior resistance to corrosion and can handle higher exhaust temperatures.

Moreover, the layout of the exhaust manifold affects the overall performance of the engine. A well-optimized manifold will reduce exhaust back pressure, enhance engine efficiency, and improve throttle response. Engineers must also consider the placement of the manifold to allow for ease of maintenance and access to other components of the engine.

Maintenance of Exhaust Manifolds

Regular maintenance of exhaust manifolds is crucial for the longevity and efficiency of marine engines. Over time, manifolds can develop cracks, corrosion, or blockages due to the harsh marine environment and the nature of exhaust gases. Inspecting for signs of wear, such as rust or leakage, should be part of routine engine maintenance.

Additionally, ensuring that the cooling system integrated with the wet manifold remains free from debris and blockages is essential for preventing overheating and associated damage. Utilizing quality materials and components during repairs or replacements will further enhance the durability and performance of the exhaust system.

Conclusion

In summary, the exhaust manifold is an essential component of marine engines, responsible for directing exhaust gases away from the engine while maintaining performance and efficiency. Understanding the types, design considerations, and maintenance requirements of exhaust manifolds can significantly impact the operation and longevity of marine engines. As technology advances, innovations in manifold design continue to improve performance, making them a critical area of focus in marine engineering. Ensuring the optimization and upkeep of the exhaust manifold will not only enhance engine performance but also contribute to better fuel efficiency and reduced environmental impact, ultimately benefiting both the operator and the oceanic ecosystem.

-

Understanding Metal Casting TechniquesNewsApr.02,2025

-

Understanding Exhaust Manifolds for Enhanced Engine PerformanceNewsApr.02,2025

-

The World of Metal FabricationNewsApr.02,2025

-

Key Components for Pump and Turbo EfficiencyNewsApr.02,2025

-

Essential Tools for Automotive Maintenance and RepairNewsApr.02,2025

-

Durable Valve Components for Effective Water ManagementNewsApr.02,2025