Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Spanish

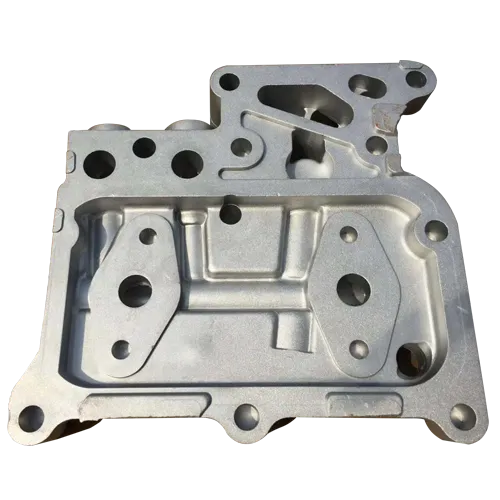

Centrifugal Impeller

Understanding the Centrifugal Impeller Principles and Applications

Centrifugal impellers are key components in various machines and systems, primarily those involved in fluid dynamics, such as pumps and turbines. Their primary function is to convert rotational energy, typically from an electric motor, into kinetic energy of the fluid. This process involves the acceleration of the liquid or gas by converting the mechanical energy imparted by the rotating impeller blades into fluid motion.

The design of a centrifugal impeller is crucial for its efficiency and performance. Typically, it comprises several blades that are curved and shaped to guide the fluid outward from the center of rotation to the outer edge. As the impeller spins, the centrifugal force generated pushes the fluid away from the center, increasing its speed and pressure. The geometry of the blades—such as their angle, width, and spacing—plays a significant role in determining the impeller's performance characteristics, including flow rate and head.

One of the most significant advantages of centrifugal impellers is their ability to handle large volumes of fluids, making them ideal for applications ranging from industrial pumps to HVAC systems

. In pumping applications, for instance, they are used to transport water, chemicals, and other liquids over varying distances. The design can be optimized for specific requirements, such as high flow rates or increased pressure, allowing for customized solutions in various industries.centrifugal impeller

Centrifugal impellers are not limited to liquid handling. In gas applications, they are found in compressors and blowers, facilitating air movement in heating and cooling systems or aiding in processes such as combustion and chemical reactions. Similarly, their design and function influence energy efficiency significantly, making them essential in applications where energy consumption and operational costs are critical.

In recent years, advancements in materials and manufacturing processes have enhanced the performance and durability of centrifugal impellers. Developments in computational fluid dynamics (CFD) enable engineers to model and simulate fluid flow around impellers, aiding in the design optimization process. Additionally, innovations such as 3D printing have opened new avenues for complex and efficient designs that were previously unfeasible.

In conclusion, centrifugal impellers are integral to various technological applications, providing efficient movement of fluids and gases. Their design considerations and operational principles are vital knowledge for engineers and industries reliant on fluid dynamics. As technology evolves, so too will the opportunities for improved designs that enhance performance and sustainability across multiple sectors.