Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Spanish

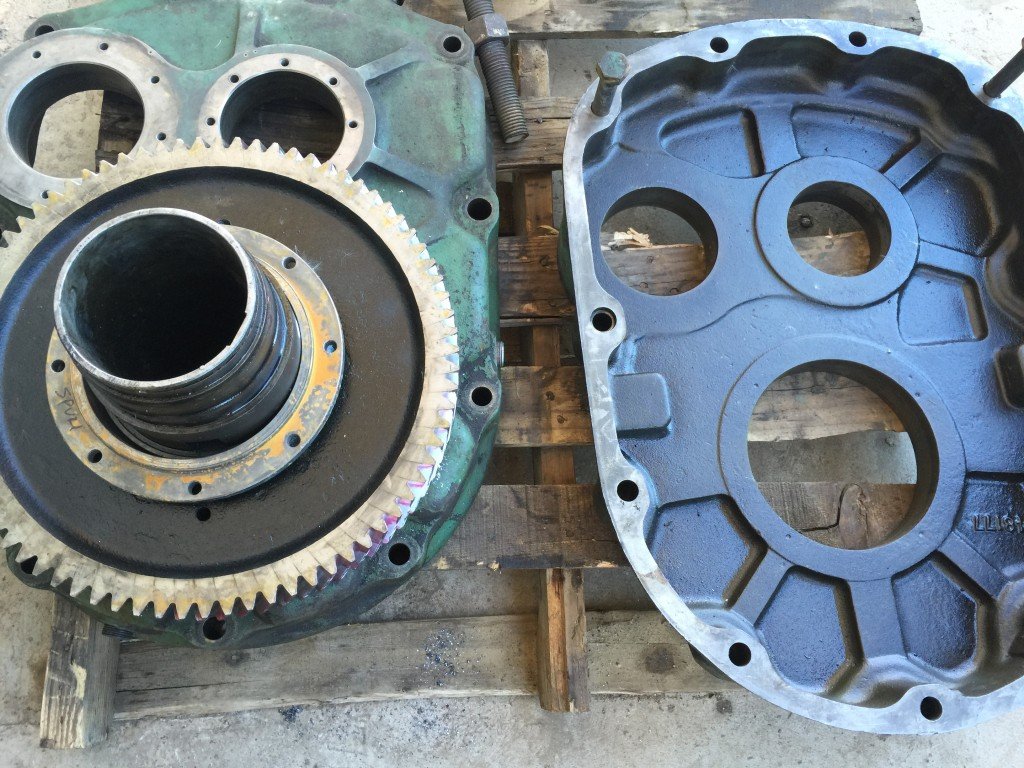

bearing end cap covers

Understanding Bearing End Cap Covers

Bearing end cap covers may not be the most glamorous components in mechanical systems, but they play a crucial role in ensuring the longevity and efficiency of machinery. Often overlooked, these covers are integral to the protection of bearings, which are vital for the smooth operation of rotating shafts in various applications, from industrial machinery to automotive systems.

What are Bearing End Cap Covers?

Bearing end cap covers serve as protective casings for bearings, positioned at the ends of the bearing housing. Their primary function is to shield the bearing from contaminants such as dust, dirt, and moisture, which can significantly impair the bearing's performance and lifespan. By preventing foreign particles from entering the bearing assembly, end cap covers help maintain a clean environment, thereby reducing the risk of premature failure.

Material and Design Considerations

The materials used for bearing end cap covers are essential for ensuring their effectiveness. Commonly made from metals, plastics, or composites, the choice of material often depends on the application's requirements, including temperature, load, and exposure to chemicals or environmental conditions. For instance, in high-temperature scenarios, heat-resistant materials such as aluminum or specially formulated plastics may be employed.

bearing end cap covers

Design plays a critical role in the functionality of bearing end cap covers, too. They must provide a snug fit to prevent any ingress of dirt or moisture while allowing for necessary ventilation to avoid pressure buildup. Many designs incorporate features like sealing rings or grooves to enhance the protective capabilities of the covers, ensuring a reliable barrier against contaminants.

Importance in Maintenance

Regular inspection and maintenance of bearing end cap covers are crucial for the overall health of machinery. Over time, wear and degradation can occur, leading to potential gaps or openings that compromise the protective function of the covers. Routine checks can help identify these issues before they escalate, allowing for timely replacements and thereby preventing costly downtime.

Moreover, the integrity of the bearing end cap covers can directly influence the performance of the bearings themselves. A damaged or poorly fitted cover can lead to contamination and increased friction, resulting in overheating and eventual failure. Thus, ensuring that these covers are in good condition is a simple yet effective way to extend the life of bearings and improve operational reliability.

Conclusion

In summary, while bearing end cap covers might seem like minor components, their importance in mechanical systems cannot be overstated. They serve as the first line of defense against environmental contaminants that could harm sensitive bearing mechanisms. By understanding their function, material considerations, and the necessity for regular maintenance, engineers and technicians can ensure the optimal performance of machinery. Ultimately, investing in high-quality bearing end cap covers and prioritizing their upkeep can lead to significant improvements in equipment efficiency and longevity, highlighting the adage that sometimes, the smallest components make the most significant impact.