Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Spanish

2 hp motor impeller price

The Impact of Impeller Design on 2% HP Motor Price

When considering the price of a 2% horsepower (HP) motor, one may not think immediately of the impeller design; however, it’s a critical component that greatly influences both cost and performance. The impeller itself is a rotating part of the motor designed to move fluid through the system, and its design can greatly impact efficiency, durability, and overall performance.

Understanding Impellers and Their Functions

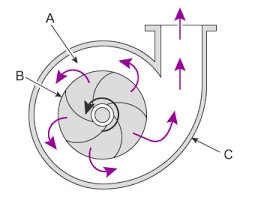

An impeller is generally a rotating component equipped with vanes or blades. Its primary function is to transfer energy from the motor to the fluid, creating flow and pressure. In many applications, especially in pumps and turbines, the efficiency of the impeller is crucial to the performance of the entire system. Different designs—such as radial, axial, or mixed flow—can yield varying results in terms of fluid dynamics and performance.

Factors Influencing Impeller Cost

1. Material The material used for the impeller has a significant impact on cost. Common materials include plastic, stainless steel, and bronze. While plastic is generally cheaper and adequate for low-power applications, stainless steel offers better durability and corrosion resistance, making it a more suitable choice for industrial applications. The choice of material directly correlates with the price of the impeller.

2. Design and Complexity The complexity of the impeller design also contributes to the cost. More complex geometries often require advanced manufacturing processes, which can increase production costs. Advanced designs may enhance efficiency, leading to energy savings over time, but can also result in a higher upfront cost.

3. Manufacturing Techniques Companies employ different manufacturing techniques such as casting, machining, or 3D printing, impacting the final price. Traditional casting might be cheaper for high-volume production, whereas 3D printing may be beneficial for low-volume or custom parts but often comes at a higher price per unit.

2 hp motor impeller price

4. Size and Capacity The size of the impeller matters. Larger impellers, which are capable of handling more fluid or creating higher pressure, typically require more material and more robust manufacturing processes, increasing their price.

Performance vs. Cost

When evaluating the cost of a 2% HP motor, it’s essential to weigh the performance benefits of the impeller against its price. A well-designed impeller may increase the system's efficiency, leading to lower operating costs over time. For example, a high-efficiency impeller can minimize power consumption, contributing to greater energy savings that can offset the initial investment in a more expensive motor or impeller.

Market Trends and Recommendations

The market for 2% HP motors is rapidly evolving, with a growing trend toward energy efficiency and sustainability. Manufacturers are increasingly investing in advanced materials and designs to create impellers that not only enhance performance but also align with eco-friendly initiatives. As a buyer, seeking out a reputable vendor that prioritizes quality and innovation can lead to better long-term value, even if the initial costs are higher.

Conclusion

In conclusion, the price of a 2% HP motor is heavily influenced by the design and quality of its impeller. Factors such as material choice, design complexity, and manufacturing techniques all play crucial roles in determining cost. While higher-quality impellers may require a larger initial investment, the potential for greater efficiency and lower operational costs must be considered. As the industry continues to advance toward energy-efficient solutions, it is essential for consumers to focus not just on the price tag, but also on the performance benefits that a well-designed impeller can bring. By doing so, they can make informed decisions that support both economic and environmental sustainability.