Mobile:+86-311-808-126-83

Email:info@ydcastings.com

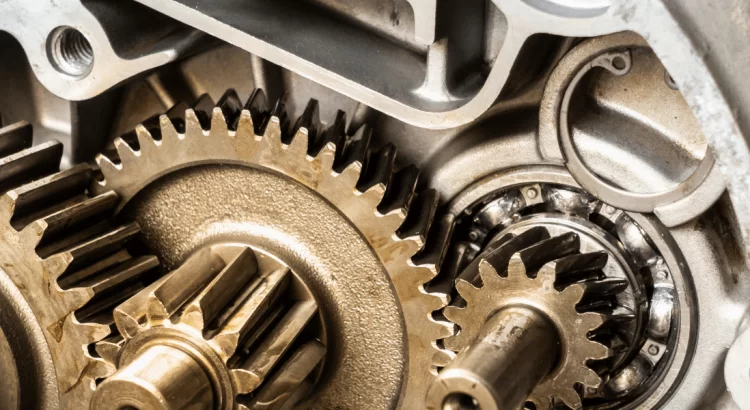

white metal casting

Understanding White Metal Casting A Comprehensive Overview

White metal casting is a specialized manufacturing process that involves the creation of metal components using alloys known as white metals. These metals are typically characterized by their silvery-white appearance and include materials such as tin, lead, zinc, and their alloys. This casting technique is prominent in various industries, ranging from automotive and aerospace to art and collectible manufacturing.

One of the key advantages of white metal casting is its ability to produce intricate and detailed designs with excellent surface finish. The low melting point of white metals allows for easy and efficient casting, making it particularly appealing for small-scale production and prototype development. The process often employs sand casting or die casting techniques, depending on the complexity of the desired part and production volume.

Materials Used in White Metal Casting

White metals, specifically alloys, form the backbone of this casting method. Tin-based alloys are popular because of their excellent casting properties and resistance to corrosion. Lead alloys were historically used as well, but due to health and environmental concerns, their use has been diminishing. Zinc and aluminum alloys are increasingly becoming the preferred materials due to their lightweight nature, strength, and enhanced environmental safety.

Applications of White Metal Casting

white metal casting

White metal casting serves a wide range of applications

. In the automotive industry, it is commonly used for manufacturing components such as engine mounts, housings for electronic devices, and decorative trims. The aerospace sector also utilizes this technique for producing lightweight parts that require high strength-to-weight ratios. Furthermore, white metal casting is widely applied in the production of detailed model kits and miniature collectibles, where the need for precision and fine detail is paramount.Advantages and Challenges

The primary advantages of white metal casting include its ability to produce complex shapes and high-definition details. It is also cost-effective for small to medium production runs. The process can accommodate various design modifications easily, providing manufacturers with the flexibility needed to refine their products.

However, white metal casting does face its share of challenges. One significant concern is the mechanical properties of the alloys used, which can sometimes fall short compared to more traditional materials like steel or aluminum. Additionally, the casting process can be sensitive to variations in temperature and material properties, which requires careful quality control to ensure consistent output.

Conclusion

In summary, white metal casting is a versatile and effective manufacturing process that caters to a multitude of industries. Its unique properties allow for the creation of complex and aesthetically pleasing components. As technology advances, the continued development of new white metal alloys and casting techniques will likely expand the possibilities of this casting method. Understanding the nuances of white metal casting is essential for industries aiming to leverage its benefits for innovative and sustainable production.

-

Why Is Choosing the Right Motor Housing Critical for Engine Performance?NewsJul.18,2025

-

Which Impeller Types Best Optimize Your Pump’s Efficiency?NewsJul.18,2025

-

Optimize Maintenance Efficiency with Durable Oil Catch SolutionsNewsJul.18,2025

-

Maximize Pump Performance with Precision-Engineered ComponentsNewsJul.18,2025

-

Elevate Industrial Flow Systems with Precision-Engineered ComponentsNewsJul.18,2025

-

Boost Durability and Functionality with Precision Power CastingsNewsJul.18,2025