Mobile:+86-311-808-126-83

Email:info@ydcastings.com

what is die cast aluminum

Understanding Die Cast Aluminum A Comprehensive Overview

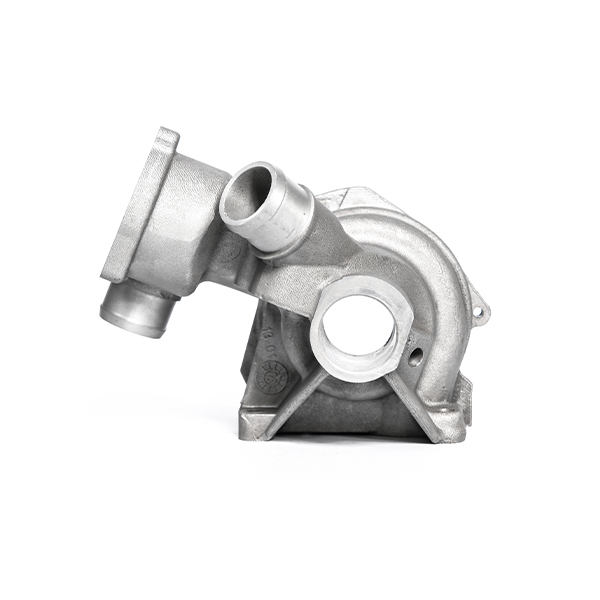

Die cast aluminum is a manufacturing process that involves pouring molten aluminum into a mold to create complex and precise shapes. This method has gained widespread popularity across various industries due to its ability to produce lightweight, durable, and intricately designed components. In this article, we will explore what die cast aluminum is, how it is produced, its advantages, and its applications.

What is Die Cast Aluminum?

Die casting is a metal casting process that involves forcing molten metal, in this case, aluminum, into a mold (or die) under high pressure. The molds used in die casting are usually made from steel and are designed to produce parts with tight tolerances and excellent surface finishes. Once the molten aluminum fills the cavity in the mold, it cools and solidifies, forming the desired shape.

There are two primary types of die casting methods hot chamber and cold chamber. The hot chamber method is primarily used for metals with low melting points, while the cold chamber method is more suitable for metals like aluminum. In the cold chamber process, molten aluminum is poured into a chamber and then injected into the mold using a plunger.

Advantages of Die Cast Aluminum

One of the main advantages of die cast aluminum is its incredible strength-to-weight ratio. Aluminum is inherently lightweight, making it an ideal choice for applications where minimizing weight is crucial, such as in automotive and aerospace industries. Additionally, die cast aluminum components have excellent dimensional accuracy and surface finish, reducing the need for post-processing and thus lowering production costs.

what is die cast aluminum

Moreover, die casting allows for high production rates, making it suitable for large-scale manufacturing. The ability to produce complex shapes in one piece also eliminates the need for assembly, further enhancing efficiency. Furthermore, aluminum is highly corrosion-resistant, adding to the longevity of products made from die cast aluminum.

Applications of Die Cast Aluminum

Die cast aluminum is utilized in a multitude of industries, including automotive, aerospace, electronics, and consumer goods. In the automotive industry, for example, it's used to manufacture engine components, transmission cases, and housing for various parts. The lightweight nature of aluminum contributes to improved fuel efficiency in vehicles.

In the aerospace sector, die cast aluminum components are crucial for structural parts and engine casings, where both strength and weight savings are paramount. The electronics industry also benefits from die cast aluminum for producing housings, heat sinks, and other components that require excellent thermal conductivity.

In consumer goods, die cast aluminum is commonly found in kitchen appliances, tools, and decorative items. The versatility of this material allows designers to create products that not only function well but also appeal aesthetically to consumers.

Conclusion

In summary, die cast aluminum is a crucial process in modern manufacturing. Its ability to create lightweight, strong, and intricately designed parts makes it invaluable across various industries. As technology continues to evolve, the methods and applications of die cast aluminum are likely to expand, further solidifying its position as a leading choice for manufacturers worldwide. With its myriad advantages, it is no surprise that die cast aluminum remains a popular choice for producing high-quality components.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025