Mobile:+86-311-808-126-83

Email:info@ydcastings.com

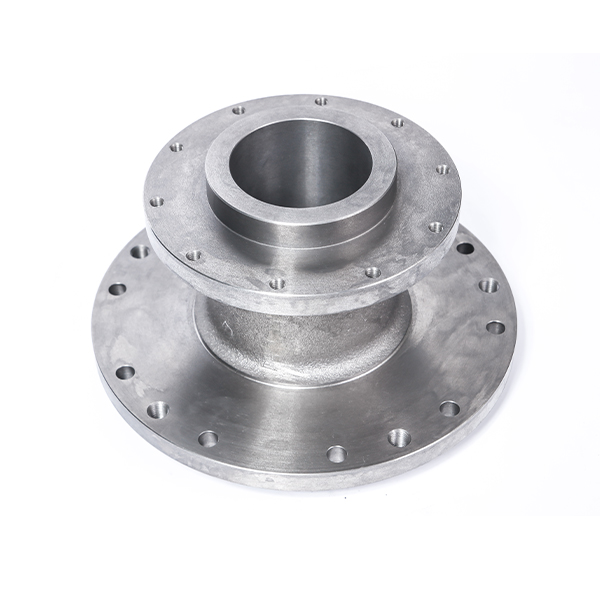

Understanding the Basics and Benefits of Aluminum Casting Techniques and Applications

Understanding Aluminum Casting A Comprehensive Overview

Aluminum casting is a pivotal process in the manufacturing industry, where molten aluminum is poured into molds to create various shapes and components. This method is valued for its ability to produce intricate designs with high dimensional accuracy, making it especially popular in industries such as automotive, aerospace, and consumer goods.

What is Aluminum Casting?

At its core, aluminum casting involves the transformation of aluminum metal into a specific shape by pouring it into a cavity or mold that has the desired dimensions and features. The casting process begins with heating aluminum to its melting point, which is approximately 660°C (1220°F), allowing it to flow freely. Once melted, the aluminum is poured into a pre-prepared mold, where it cools and solidifies into the final product.

Types of Aluminum Casting Processes

There are several methods of aluminum casting, each with its own advantages and applications. The most common casting methods include

1. Sand Casting This is one of the oldest and most versatile casting methods. Molds are made from sand mixed with a binding agent. The molten aluminum is poured into these molds, which are then broken apart to reveal the finished part. Sand casting is suitable for large components and allows for complex geometries.

2. Die Casting In this process, molten aluminum is injected under pressure into a steel mold or die. This technique is ideal for producing small to medium-sized parts with excellent surface finish and tight tolerances. Die casting is widely used in applications requiring high production rates.

3. Investment Casting Also known as lost wax casting, this method involves creating a wax pattern coated in a ceramic shell. Once the shell hardens, the wax is melted away, leaving a cavity into which aluminum is poured. This process is perfect for intricate designs and precision components.

4. Permanent Mold Casting In this technique, a reusable metal mold is used, which can withstand high temperatures. The aluminum is poured into the mold, and after cooling, the mold is removed to reveal the finished part. This method is known for producing strong parts with a good surface finish.

what is aluminum casting

Advantages of Aluminum Casting

Aluminum casting offers numerous benefits, making it a preferred choice for many manufacturers

- Lightweight Properties Aluminum is significantly lighter than many other metals, which is essential in industries like automotive and aerospace where weight reduction can lead to enhanced fuel efficiency. - Corrosion Resistance Aluminum naturally forms a protective oxide layer, making cast aluminum components resistant to corrosion, thus extending the life of the products.

- Design Versatility The casting process allows for a high degree of design flexibility, enabling manufacturers to produce complex shapes and components that would be difficult or impossible to achieve with other fabrication methods.

- Cost-Effectiveness Aluminum casting can be highly efficient, especially in high-volume production, which helps to reduce costs per unit.

Applications of Aluminum Casting

The versatility of aluminum casting makes it suitable for a wide range of applications. In the automotive industry, cast aluminum parts are used in engines, transmission cases, and wheels. The aerospace sector relies on aluminum castings for structural components due to their strength-to-weight ratio. Furthermore, consumer products like cookware and electronic casings also benefit from aluminum casting, showcasing the material’s broad applicability.

Conclusion

In summary, aluminum casting is an essential manufacturing process that offers numerous advantages and applications. With the increasing demand for lightweight and durable materials, aluminum casting will continue to play a critical role in shaping the future of manufacturing across various industries. Whether it’s in the heat of an engine or the elegant design of household items, the impact of aluminum casting is profound and far-reaching.

-

Impeller Technology That Powers Precision in Pump SystemsNewsMay.22,2025

-

Valve Durability Begins with Quality Cast Iron ComponentsNewsMay.22,2025

-

Performance Cooling with Advanced Automobile Water Pump SolutionsNewsMay.22,2025

-

How Motor Housing and Oil Pans Shape Engine PerformanceNewsMay.22,2025

-

How Metal Castings Drive Modern Manufacturing EfficiencyNewsMay.22,2025

-

Exploring the Engineering Behind Valve Body CastingsNewsMay.22,2025