Mobile:+86-311-808-126-83

Email:info@ydcastings.com

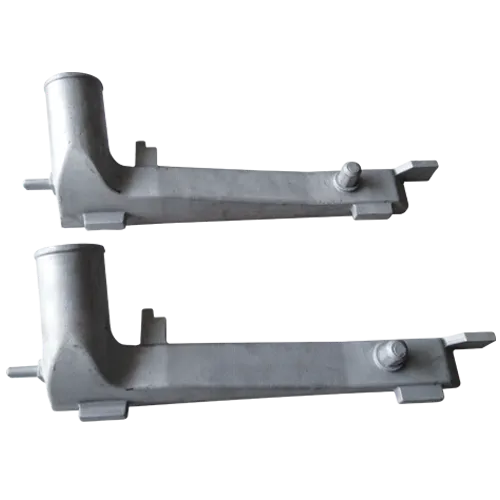

wc6 valve body

Understanding the WC6% Valve Body An Essential Component for Fluid Control

The WC6% valve body plays an integral role in various industrial applications, particularly in the field of fluid control. It acts as the heart of many systems, facilitating the efficient flow of liquids and gases. This article delves into the characteristics, applications, and significance of the WC6% valve body, highlighting its importance in contemporary industrial processes.

What is the WC6% Valve Body?

The WC6% valve body is constructed from a specific alloy that contains around 6% tungsten, which provides it with unique properties. This material is chosen for its robustness and ability to withstand extreme conditions such as high temperature, pressure, and corrosive environments. The valve body serves as a housing for valve components such as the disc, seat, and actuator, making it a crucial part of the valve assembly.

The design of the WC6% valve body is typically oversized to ensure reliability and durability. The geometry of the valve body is engineered to minimize friction and wear, enhancing its operational lifespan and reducing maintenance costs. Furthermore, the precision manufacturing processes applied in creating these valve bodies ensure that they meet stringent industry standards for quality and performance.

Applications of WC6% Valve Body

Due to its desirable properties, the WC6% valve body finds applications in various sectors including

1. Oil and Gas Industry In this sector, valves are essential for regulating the flow of hydrocarbons. The WC6% valve body can withstand the harsh environments typically found in oil rigs and refineries, ensuring safe and efficient operations.

2. Chemical Processing The resistance to corrosion makes the WC6% valve body ideal for chemical processing plants that handle aggressive substances. The integrity of the valve body ensures that it maintains functionality without compromising safety.

3. Power Generation In power plants, especially those using steam, the demand for high-performance valves is critical. The WC6% valve body can operate effectively in high-temperature and high-pressure environments, crucial for maintaining efficiency in steam generation and turbine operations.

wc6 valve body

4. Water Treatment Facilities Valves made with WC6% valve bodies help manage the flow of water during treatment processes. Their durability and resistance to corrosion are key factors in ensuring longevity and effectiveness in water management systems.

Advantages of WC6% Valve Body

The incorporation of WC6% material in valve body construction offers several advantages

- High Strength and Durability The alloy provides high tensile strength, making it suitable for demanding applications. This durability translates into a longer lifespan for valves, reducing replacement and repair costs.

- Corrosion Resistance The inherent properties of WC6% alloys make them resistant to a range of chemicals, which is critical in preventing leaks and failures in corrosive environments.

- Thermal Stability These valve bodies can maintain integrity and functionality across a wide range of temperatures, ensuring consistent operation even in extreme heat.

- Reduced Maintenance The longevity and robustness of the WC6% valve body lead to decreased maintenance requirements, allowing operators to focus on productivity instead of frequent repairs.

Conclusion

The WC6% valve body is a vital component in numerous industries where fluid control is paramount. Its unique combination of strength, corrosion resistance, and thermal stability makes it an ideal choice for applications ranging from oil and gas to chemical processing and power generation. As industries continue to evolve and face increasingly challenging operational conditions, the demand for reliable and efficient valve bodies like the WC6% will only grow.

In summary, understanding the WC6% valve body and its applications not only highlights the importance of material science in engineering but also underscores the necessity for innovation in fluid control technologies. As industries strive for greater efficiency and safety, the role of advanced materials such as those used in the WC6% valve body becomes increasingly significant, paving the way for more sustainable industrial practices.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025