Mobile:+86-311-808-126-83

Email:info@ydcastings.com

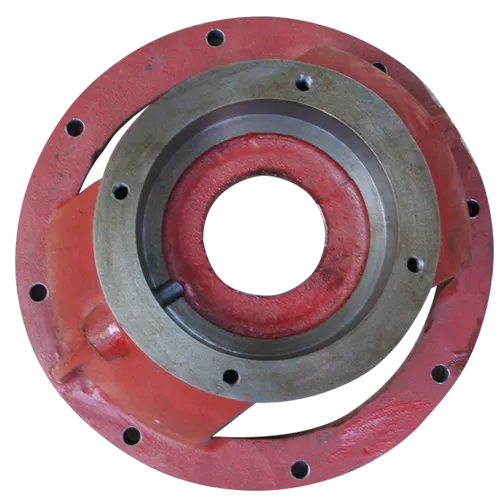

Design and Functionality of Water Pump Casings for Enhanced Performance and Durability

Understanding Water Pump Casings Importance and Materials

Water pump casings play a crucial role in the efficient operation of pump systems used in a variety of applications, from irrigation and municipal water supply to industrial processes. As the housing that encloses the pump components, the casing is essential for guiding the flow of water, protecting internal components, and facilitating maintenance. This article explores the significance of water pump casings and the materials commonly used in their construction.

The primary function of a water pump casing is to provide structural support for the pump assembly

. It ensures that all components, including the impeller and motor, are securely held in place, allowing for optimal performance during operation. Proper casing design can significantly influence the pump's efficiency, pressure stability, and overall durability. Additionally, the casing plays a vital role in minimizing leakage and protecting the pump from external contaminants, which could otherwise impair performance and lead to premature failure.When selecting materials for pump casings, several factors must be considered, including corrosion resistance, strength, weight, and cost. Common materials for water pump casings include cast iron, stainless steel, and various polymers.

water pump casing

Cast iron is widely used for its durability and cost-effectiveness. It's an excellent choice for handling large volumes of water and can withstand significant stress. However, cast iron is prone to corrosion if exposed to aggressive environments, making it less ideal for applications involving harsh chemicals or saltwater.

Stainless steel is another popular option, especially in applications where corrosion resistance is paramount. It offers superior protection against rust and can endure a wide range of temperatures and pressures, making it suitable for industrial and municipal water systems. The enhanced longevity of stainless steel casings can also justify the higher initial cost.

Polymer casings, such as those made from thermoplastic materials, have gained traction due to their lightweight nature and excellent resistance to corrosive substances. These materials are often used in smaller pumps or in applications where weight savings are critical.

In conclusion, selecting the right water pump casing material is essential for ensuring the longevity and efficiency of a pump system. Understanding the various options available, based on specific application needs, helps in making informed decisions that enhance performance and reduce maintenance costs. Properly designed and constructed casings not only protect the pump but also contribute to the overall effectiveness of water management systems.

-

Impeller Technology That Powers Precision in Pump SystemsNewsMay.22,2025

-

Valve Durability Begins with Quality Cast Iron ComponentsNewsMay.22,2025

-

Performance Cooling with Advanced Automobile Water Pump SolutionsNewsMay.22,2025

-

How Motor Housing and Oil Pans Shape Engine PerformanceNewsMay.22,2025

-

How Metal Castings Drive Modern Manufacturing EfficiencyNewsMay.22,2025

-

Exploring the Engineering Behind Valve Body CastingsNewsMay.22,2025