Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Understanding the Role of Vortex Casing in Centrifugal Pump Efficiency and Performance

Understanding Vortex Casing in Centrifugal Pumps

Centrifugal pumps are fundamental components in various industries, used to transport fluids by converting rotational kinetic energy into hydrodynamic energy. One of the significant innovations in centrifugal pump design is the incorporation of vortex casings, which enhance the efficiency and performance of these pumps under certain operating conditions. This article delves into the anatomy and function of vortex casings, their advantages, and their applications in modern pumping systems.

The Anatomy of Vortex Casing

A vortex casing can be generally defined as a specialized pump housing designed to minimize hydraulic losses and improve flow characteristics. In traditional centrifugal pump designs, fluid enters the impeller, where it is accelerated outward to increase its energy before being discharged. However, this process can create significant turbulence and energy losses, especially in cases of off-design operating conditions.

The vortex casing addresses this issue by creating a controlled flow pattern. The design typically features a volute or a spiral configuration that allows the fluid to spiral around the impeller, thereby promoting a more uniform flow rate and reducing the likelihood of cavitation. The casing is engineered to maintain a low-pressure zone, which helps in creating a vortex effect that enhances fluid movement even at low flow rates.

Advantages of Vortex Casing

1. Improved Efficiency One of the most notable benefits of using vortex casings is improved hydraulic efficiency. By minimizing turbulence and energy losses that occur in conventional designs, vortex casings allow for higher flow rates without significantly increasing power consumption.

2. Reduced Cavitation Risk Cavitation, a phenomenon where vapor bubbles form and collapse in the liquid, can cause severe damage to pump components. Vortex casings are designed to create low-pressure zones that efficiently transport fluids without reaching the critical pressure that leads to cavitation. This feature extends the pump's operational life and reliability.

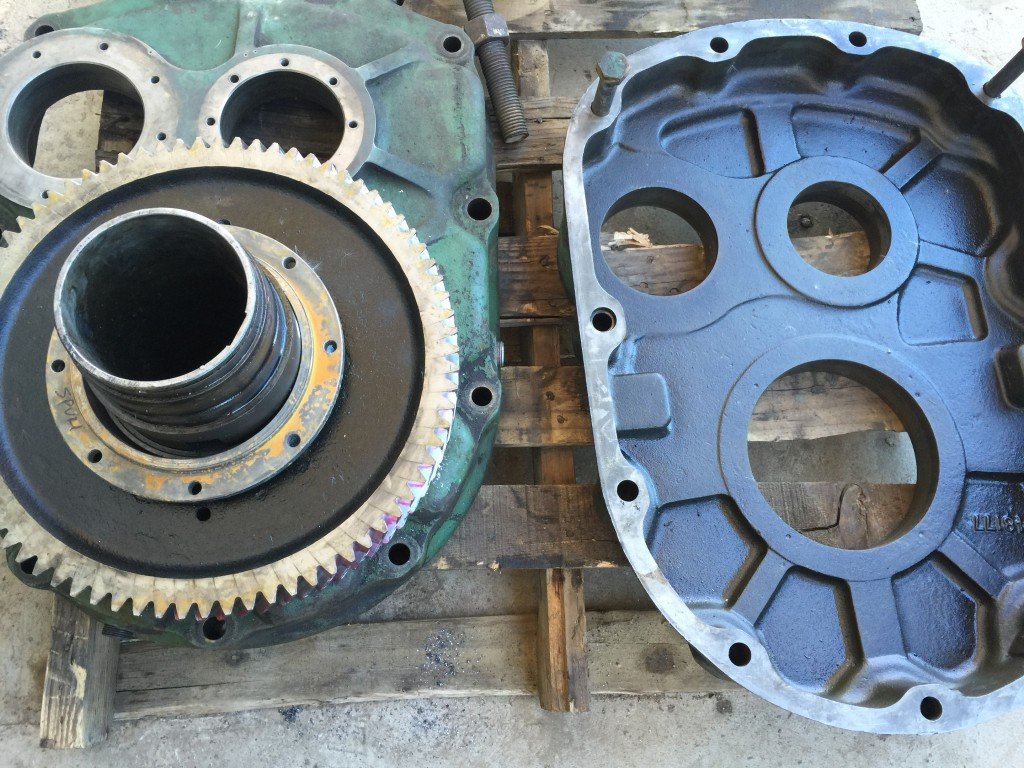

vortex casing in centrifugal pump

3. Enhanced Self-Priming Capability Vortex casing pumps can effectively handle fluids with high levels of air or gas, making them suitable for self-priming operations. This capability is particularly useful in applications where fluid levels fluctuate or where the pump may need to be positioned above the fluid source.

4. Versatility These pumps are versatile and can be used in various applications, from wastewater treatment to agricultural irrigation and chemical processing. Their design can be customized to accommodate different fluid types and flow conditions, enhancing their applicability across multiple sectors.

Applications of Vortex Casing Pumps

Vortex casing pumps find their place in numerous industries due to their unique advantages. In water treatment facilities, they are employed for moving sludge and other viscous materials without clogging. Similarly, in the agricultural sector, vortex casing pumps are used for irrigation systems that require high volume flow rates with minimal energy input.

Chemical processing plants also utilize these pumps to handle corrosive or viscous fluids safely. Their design minimizes the risk of damage to the pump, ensuring consistent and reliable performance. Moreover, vortex casing pumps are valuable in industries where fluid characteristics can dramatically change, such as oil and gas, where varying levels of gas entrainment are common.

Conclusion

The integration of vortex casings in centrifugal pumps represents a significant advancement in pump technology. By enhancing efficiency, reducing cavitation risk, and enabling self-priming capabilities, these pumps provide a robust solution for various fluid transport challenges across multiple industries. As demand for energy-efficient and reliable pumping solutions continues to grow, the role of vortex casing pumps will likely expand, driving innovation and improvements in fluid management systems worldwide. Understanding these pumps' unique features can lead to better-informed decisions in selecting the appropriate pumping solutions for specific applications, ultimately contributing to improved operational efficiency and reduced maintenance costs.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025