Mobile:+86-311-808-126-83

Email:info@ydcastings.com

English

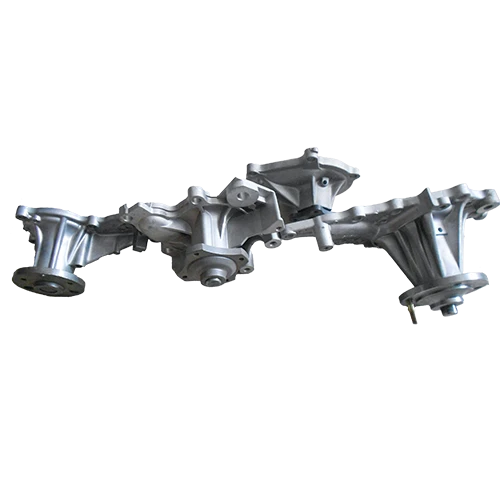

valve end cap

Understanding Valve End Caps A Comprehensive Guide

In the world of plumbing, fluid dynamics, and various industrial applications, valve end caps are a crucial component often overlooked until they become essential in a specific project. These fittings play a significant role in the integrity and functionality of numerous systems ranging from water distribution to chemical processing. This article delves into what valve end caps are, their types, functions, and importance across various industries.

What is a Valve End Cap?

A valve end cap is a fitting used to seal the end of a pipe or fitting. Its primary purpose is to create a barrier that prevents the flow of liquids or gases. Valves themselves are crucial for controlling the flow, but when a line needs to be terminated or closed off, an end cap is often employed. Constructed from various materials such as plastic, PVC, metal, or rubber, these caps are designed to withstand different pressures and temperatures, ensuring the system's reliability.

Types of Valve End Caps

Valve end caps come in various types to accommodate the diverse needs of different applications

1. Threaded End Caps These caps have internal threads that allow for easy installation and removal. They are typically used in applications where frequent access to the pipeline is needed.

2. Welded End Caps Designed for permanent fixtures, welded end caps are typically used in high-pressure systems. They are welded to the pipe ends, creating a robust seal that can handle extreme conditions.

3. Flanged End Caps These caps come with flat surfaces and holes for bolts, allowing for easy attachment to flanged pipe systems. They are commonly used in industrial settings where disassembly is occasionally required.

4. Ductile Iron and Steel Caps Mostly used in water and gas applications, these caps are designed for durability and can withstand harsh environments.

Functions of Valve End Caps

The primary function of valve end caps is to seal off the ends of pipes, but they serve additional purposes, including

valve end cap

- Pressure Management By capping open ends, end caps help to maintain the desired pressure within a piping system, preventing leaks and ensuring efficient operation. - System Integrity Valve end caps protect the piping system from contaminants and external elements, which can cause corrosion, blockages, or other forms of damage.

- Flow Control In certain applications, end caps are crucial for controlling flow direction and ensuring that systems function optimally.

- Safety Properly installed end caps prevent accidental leakages of hazardous materials, ensuring the safety of workers and the environment.

Importance Across Industries

Valve end caps are essential in various industries, including

- Municipal Water Supply Used extensively in water treatment and distribution systems, valve end caps help maintain system pressure and integrity.

- Oil and Gas These caps are integral in the transportation of oil and gases through pipelines, ensuring that hazardous materials are safely contained.

- Manufacturing and Chemical Processing In factories that deal with chemicals, valve end caps are used to secure lines and tanks, preventing spills and maintaining a safe working environment.

- HVAC Systems In heating, ventilation, and air conditioning systems, valve end caps are vital for sealing and maintaining airflow efficiency.

Conclusion

In summary, valve end caps are small yet vital components that help ensure the functionality, safety, and reliability of piping systems across various applications and industries. Understanding their types, functions, and importance can lead to better design and maintenance practices, ultimately enhancing system performance and longevity. Whether in residential plumbing or large-scale industrial operations, the role of valve end caps cannot be underestimated. They are a testament to the importance of seemingly minor components in the intricate web of fluid dynamics and mechanical engineering.

-

Materials Used in Manufacturing Cap End Pipe FittingsNewsNov.24,2025

-

Material Properties of CF8M CastingNewsNov.24,2025

-

How to Inspect Pump Cap Ends for DamageNewsNov.21,2025

-

Backward Curved Impeller – Efficient Airflow Solutions for Industry | YD CastingsNewsNov.21,2025

-

Automobile Water Pump - Efficient, Quiet, Durable & ElectricNewsNov.21,2025

-

Impeller for Pumps – High-Efficiency, Durable, OEM-ReadyNewsNov.21,2025