Mobile:+86-311-808-126-83

Email:info@ydcastings.com

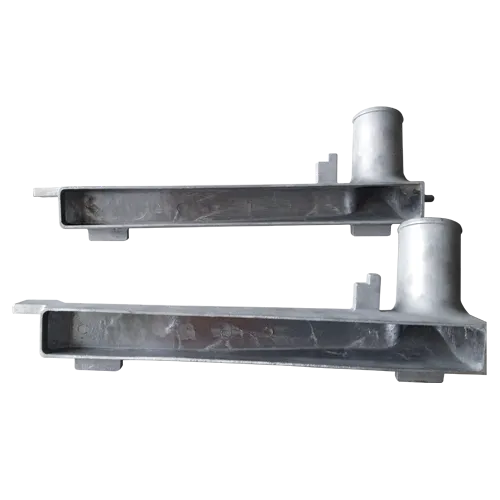

valve end cap

The Importance and Functionality of Valve End Caps

When discussing industrial and plumbing applications, one often comes across various components that might seem mundane but hold significant importance in ensuring efficiency, safety, and reliability. Among these components, valve end caps play a pivotal role. These small yet essential items are designed to seal the ends of a valve structure, providing a range of functionalities from containment to protection. This article delves into the significance of valve end caps, their applications, materials, and the reasons they are a critical part of many systems.

Understanding Valve End Caps

Valves are crucial for controlling the flow of liquids and gases within piping systems. A valve end cap is a fitting used to cover the open end of a valve body. It is designed to provide a secure seal, preventing leaks and ensuring that the system operates effectively. These caps can be permanently attached or removable, depending on the design and purpose of the valve. They can also be found in various shapes and sizes, tailored to fit different types of valves such as ball valves, gate valves, and swing check valves.

Applications of Valve End Caps

Valve end caps are ubiquitous in various industries including oil and gas, water treatment, chemical manufacturing, and HVAC systems. In the oil and gas industry, for instance, these caps are used to secure valves that control the flow of hydrocarbons, thus ensuring that no hazardous materials escape into the environment. Similarly, in water treatment facilities, end caps help maintain water quality by preventing contamination through leaks.

In chemical manufacturing, valve end caps are essential for maintaining the integrity of the chemical process

. They are used to safeguard against spills and leaks, which can be costly both economically and environmentally. Additionally, in HVAC systems, these caps are often employed to seal off valves that are not currently in use, thus improving energy efficiency.Materials Used for Valve End Caps

valve end cap

The materials used in the manufacture of valve end caps are critical to their functionality. Common materials include stainless steel, brass, plastic, and rubber. Stainless steel is favored in high-pressure applications due to its durability and resistance to corrosion. Brass, on the other hand, is often used for its excellent sealing properties and ability to withstand varying temperatures.

Plastic end caps are popular in applications where weight is a concern, or where the chemical properties of the fluid being contained may react with metals. Rubber end caps provide flexibility and are often used in systems where vibration might otherwise loosen other types of fittings. The choice of material typically depends on the specific requirements of the application, including temperature, pressure, and chemical compatibility.

Utility and Maintenance

Maintaining valve end caps is essential for ensuring their longevity and effectiveness. Regular inspections can identify any wear and tear or potential leaks before they become significant issues. Proper installation is equally crucial; incorrect fitting can lead to system failures, resulting in costly repairs and downtime.

It’s also worth noting that when valves need to be serviced or replaced, end caps can facilitate easier access to the internal components of the valve. By providing a clean and secure point of closure, they help to streamline maintenance procedures.

Conclusion

In conclusion, valve end caps may be small components, but their role in industrial and plumbing systems is invaluable. They provide essential sealing capabilities that prevent leaks, enhance safety, and contribute to the overall efficiency of various systems. With a variety of materials tailored for different applications, these fittings ensure that valves can effectively control fluid flow without compromising system integrity. Regular maintenance and proper installation further augment their functionality, proving that sometimes, it’s the little things that make a big difference in industrial operations. Whether in a factory, an oil rig, or a water treatment facility, valve end caps are indeed unsung heroes of modern engineering.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025