Mobile:+86-311-808-126-83

Email:info@ydcastings.com

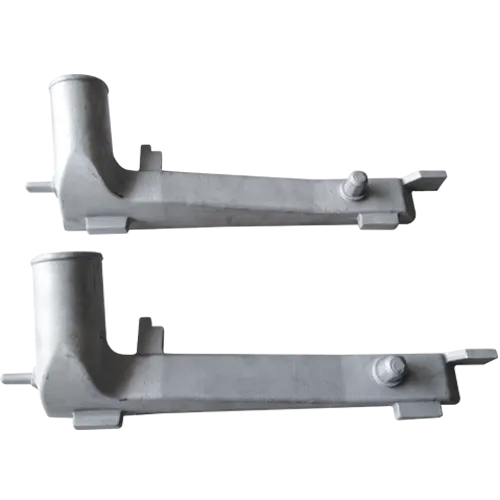

valve casting suppliers

Valves and Casting The Key Role of Suppliers

Valves are critical components in various industrial applications, from oil and gas to water treatment and manufacturing. They control the flow of liquids and gases, ensuring efficient operation and safety in numerous processes. Behind the production of these vital components lies a crucial aspect of manufacturing valve casting suppliers. Their role in the supply chain is indispensable, and understanding their significance can shed light on the challenges and innovations within the industry.

Valve casting involves creating intricate shapes from molten metal. This process requires precision and quality, as even the slightest defect can lead to operational failures and safety hazards. Suppliers in this niche must meet stringent standards, such as ASTM and ISO certifications, to ensure that their products comply with industry regulations. Selecting the right casting supplier involves assessing their experience, technology, and ability to produce custom parts tailored to specific requirements.

The demand for high-quality valve casting has been rising due to increased industrial activities globally. Suppliers have responded to this demand by adopting advanced technologies, such as 3D printing and computer-aided design (CAD). These innovations allow for more complex designs, reduced waste, and lower production costs. However, the enhancing technology must be balanced with maintaining traditional craftsmanship, which is vital for producing robust and reliable valves.

valve casting suppliers

Furthermore, quality assurance is a significant focus for valve casting suppliers. Implementing rigorous testing methods, from non-destructive testing (NDT) to pressure tests, ensures that the valves perform optimally in their respective applications. This dedication to quality not only enhances the supplier’s reputation but also guarantees customer satisfaction and trust.

In an increasingly competitive market, valve casting suppliers must also be sensitive to pricing and lead times. Efficient logistics and supply chain management can significantly impact a supplier's ability to meet customer demands while staying cost-effective. This necessitates strong relationships with raw material suppliers and a commitment to sustainable practices, as environmental concerns become more pressing.

In conclusion, valve casting suppliers play a pivotal role in the industrial landscape. Their commitment to quality, innovation, and customer service defines the performance and safety of valves, ultimately impacting a wide range of industries. As technology continues to advance and market demands evolve, these suppliers will need to adapt to remain relevant and provide the essential services that keep the world's industries flowing smoothly.

-

Impeller Technology That Powers Precision in Pump SystemsNewsMay.22,2025

-

Valve Durability Begins with Quality Cast Iron ComponentsNewsMay.22,2025

-

Performance Cooling with Advanced Automobile Water Pump SolutionsNewsMay.22,2025

-

How Motor Housing and Oil Pans Shape Engine PerformanceNewsMay.22,2025

-

How Metal Castings Drive Modern Manufacturing EfficiencyNewsMay.22,2025

-

Exploring the Engineering Behind Valve Body CastingsNewsMay.22,2025