Mobile:+86-311-808-126-83

Email:info@ydcastings.com

German

Feb. . 19, 2025 05:45

Back to list

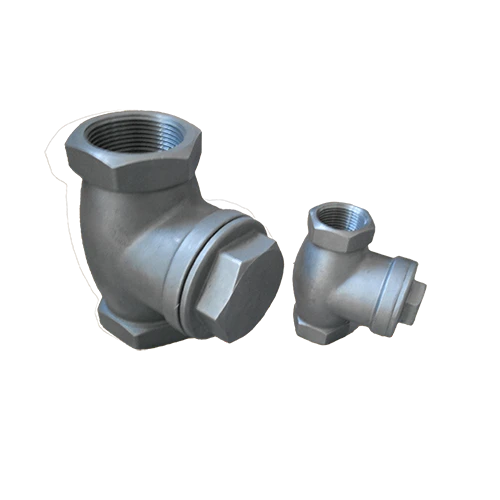

valve body

Navigating the intricate world of valve bodies, this article delves into the core of what makes these critical components both fascinating and essential in various industrial applications. A valve body, often overlooked, is a pivotal part of hydraulic systems, fundamentally responsible for controlling fluid flow within these complex systems. This piece seeks to enhance your understanding, position you as an informed decision-maker, and ensure any valve body-related choices contribute positively to overall system performance and longevity.

Trustworthy Maintenance Practices The lifetime of a valve body is directly proportional to the diligence exercised in its maintenance. A valve body that remains unchecked can lead to malfunctions and costly repairs. Regular maintenance involves inspection of the internal channels for blockages, ensuring seals and gaskets are in sound condition, and keeping the body free of external damage. My years as a maintenance engineer taught me that 70% of hydraulic failures can be traced back to neglected valve bodies. Thus, instituting a proactive maintenance schedule can mitigate potential failures, ensuring sustained system performance. Innovations Shaping the Future Recent advancements in digital technology have introduced intelligent valve bodies. These valve bodies come equipped with sensors that provide real-time data on system performance, signaling potential issues before they escalate. The integration of IoT into valve systems enables remote monitoring and data analytics, which translates into maximizing uptime and reducing service costs. Choosing a Valve Body Manufacturer The global market offers a plethora of manufacturers, yet not all are created equal. Experience with reputable manufacturers can ultimately safeguard against subpar performance and potential system failures. Consider firms that guarantee customization options, allowing for solutions tailored to specific operational requirements, thereby ensuring an optimal match between system demands and component capabilities. Conclusion Valve bodies might be one of the less glorified components within hydraulic systems, yet their role is indispensable. Understanding their function, material strengths, and maintenance demands, coupled with staying informed on technological advancements, allows for informed decisions that enhance both immediate and long-term operational efficiencies. Emphasizing expertise and authority in discussing valve bodies not only builds trust with stakeholders but also ensures that systems perform flawlessly, maximizing productivity and minimizing unexpected interruptions. Therefore, investing in high-quality valve bodies and consistent maintenance practices is not just cost-effective but strategic in maintaining an edge in industrial and automotive environments.

Trustworthy Maintenance Practices The lifetime of a valve body is directly proportional to the diligence exercised in its maintenance. A valve body that remains unchecked can lead to malfunctions and costly repairs. Regular maintenance involves inspection of the internal channels for blockages, ensuring seals and gaskets are in sound condition, and keeping the body free of external damage. My years as a maintenance engineer taught me that 70% of hydraulic failures can be traced back to neglected valve bodies. Thus, instituting a proactive maintenance schedule can mitigate potential failures, ensuring sustained system performance. Innovations Shaping the Future Recent advancements in digital technology have introduced intelligent valve bodies. These valve bodies come equipped with sensors that provide real-time data on system performance, signaling potential issues before they escalate. The integration of IoT into valve systems enables remote monitoring and data analytics, which translates into maximizing uptime and reducing service costs. Choosing a Valve Body Manufacturer The global market offers a plethora of manufacturers, yet not all are created equal. Experience with reputable manufacturers can ultimately safeguard against subpar performance and potential system failures. Consider firms that guarantee customization options, allowing for solutions tailored to specific operational requirements, thereby ensuring an optimal match between system demands and component capabilities. Conclusion Valve bodies might be one of the less glorified components within hydraulic systems, yet their role is indispensable. Understanding their function, material strengths, and maintenance demands, coupled with staying informed on technological advancements, allows for informed decisions that enhance both immediate and long-term operational efficiencies. Emphasizing expertise and authority in discussing valve bodies not only builds trust with stakeholders but also ensures that systems perform flawlessly, maximizing productivity and minimizing unexpected interruptions. Therefore, investing in high-quality valve bodies and consistent maintenance practices is not just cost-effective but strategic in maintaining an edge in industrial and automotive environments.

Related PRODUCTS