Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Vacuum Pump Connector Solutions for Efficient System Integration and Performance Enhancement

Understanding Vacuum Pump Connectors An Essential Component in Industrial Applications

In various industrial and scientific applications, vacuum pumps play a crucial role in creating and maintaining low-pressure environments. These devices are often connected to systems through vacuum pump connectors, which facilitate the transfer of gases, liquids, and other materials efficiently. This article delves into the importance of vacuum pump connectors, their types, applications, and maintenance practices to ensure optimal performance.

What Are Vacuum Pump Connectors?

Vacuum pump connectors are specialized fittings that link the vacuum pump to tubing, instruments, or other components within the vacuum system. These connectors are designed to maintain a tight seal to prevent leaks, which is critical in vacuum applications where even the smallest leak can significantly affect performance. They are typically constructed from durable materials such as stainless steel, plastic, or rubber, tailored to withstand the specific pressures and temperatures of the system.

Types of Vacuum Pump Connectors

1. Flanged Connectors These are widely used in vacuum systems due to their ability to provide a secure and leak-proof seal. Flanged connectors consist of two flanges that are bolted together, often incorporating a gasket to enhance sealing.

2. Quick-Connect Connectors These connectors allow for fast and easy assembly and disassembly of vacuum systems. They employ a push-to-connect mechanism, making them ideal for applications where frequent changes or maintenance are required.

3. Tube Fittings Often made of stainless steel or other rigid materials, tube fittings are used for connecting rigid tubing in vacuum systems. They ensure a secure connection, preventing any air ingress that could disrupt the vacuum.

4. Hose Connectors In applications where flexible tubing is necessitated, hose connectors are utilized. These connectors typically feature clamps or collars to secure the connection.

Applications of Vacuum Pump Connectors

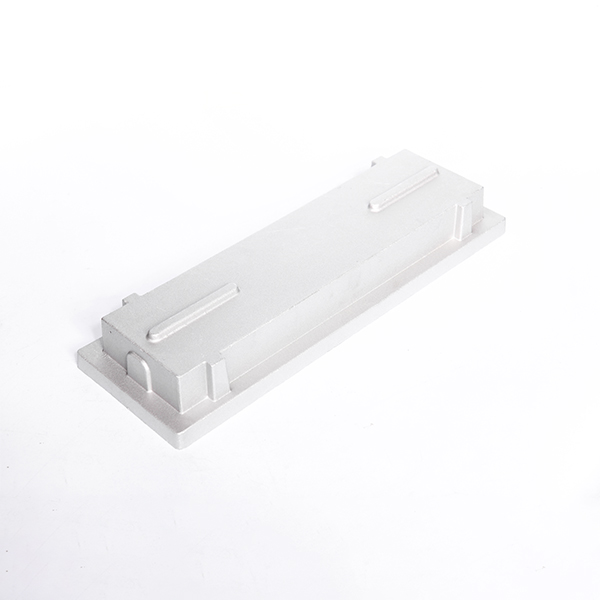

vacuum pump connector

Vacuum pump connectors find applications across a wide range of industries. In the laboratory setting, vacuum pumps are frequently used in sample preparation, vacuum distillation, and other analytical processes. In the manufacturing sector, these connectors are essential in systems involving packaging, vacuum forming, and drying processes.

Moreover, in the food and pharmaceutical industries, vacuum pumps help in preserving products and ensuring sterilization

. Properly functioning vacuum pump connectors are vital in these applications to maintain product quality and safety.Maintenance of Vacuum Pump Connectors

To ensure the longevity and efficiency of vacuum pump connectors, regular maintenance is essential. Here are some recommended practices

- Inspection Routine checks should be performed to identify any signs of wear, corrosion, or damage. Replacing worn components promptly can prevent leaks and system failures.

- Cleaning Debris or contaminants can compromise the integrity of the connectors. Regular cleaning with appropriate solvents and tools will keep the connectors in optimal condition.

- Tightening Connections Over time, connections may loosen due to vibrations or temperature changes. Periodically tightening flanged or threaded connections can help maintain a leak-free system.

- Replacement If connectors show significant wear or are unable to maintain a proper seal, they should be replaced immediately to prevent system degradation.

Conclusion

In conclusion, vacuum pump connectors are indispensable in maintaining the efficiency and performance of vacuum systems across various sectors. Understanding the different types of connectors and their applications can help users make informed decisions when designing or maintaining vacuum systems. By implementing regular maintenance practices, industries can ensure that their vacuum systems operate effectively, minimizing downtime and enhancing productivity. As technology advances, so will the design and capabilities of vacuum pump connectors, further solidifying their role as critical components in modern industrial processes.

-

Impeller Technology That Powers Precision in Pump SystemsNewsMay.22,2025

-

Valve Durability Begins with Quality Cast Iron ComponentsNewsMay.22,2025

-

Performance Cooling with Advanced Automobile Water Pump SolutionsNewsMay.22,2025

-

How Motor Housing and Oil Pans Shape Engine PerformanceNewsMay.22,2025

-

How Metal Castings Drive Modern Manufacturing EfficiencyNewsMay.22,2025

-

Exploring the Engineering Behind Valve Body CastingsNewsMay.22,2025