Mobile:+86-311-808-126-83

Email:info@ydcastings.com

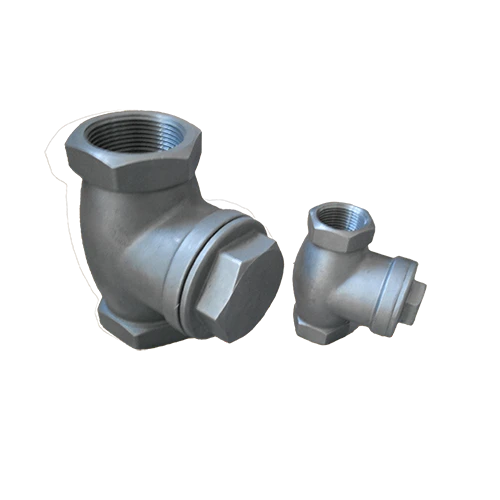

turbo compressor housing

Understanding Turbo Compressor Housing A Key Component in Turbocharging Systems

Turbo compressor housings are critical components in turbocharger systems, playing a fundamental role in enhancing engine performance and efficiency. These housings are designed to encase the turbine and compressor elements of a turbocharger, directing airflow and ensuring optimal operation under various conditions.

At its core, the turbo compressor housing serves several important functions. Primarily, it provides structural support to the turbine and compressor wheels, which are responsible for compressing air before it enters the engine’s combustion chamber. This compression process allows for a greater volume of air to mix with fuel, leading to a more powerful combustion event and increased engine output. The design of the housing must ensure minimal turbulence and resistance, facilitating a smoother airflow which is vital for achieving maximum efficiency.

Furthermore, turbo compressor housings are engineered to withstand extreme temperatures and pressures. During operation, a turbocharger can reach soaring temperatures and high-stress levels due to the rapid spinning of the turbine and the high-velocity air being compressed. Therefore, the materials used in the housing construction are essential. Typically, manufacturers use high-quality aluminum alloys or cast iron, which offer the necessary strength and thermal resistance to prevent warping or failure during use.

turbo compressor housing

Another crucial aspect of turbo compressor housings is their influence on boost dynamics. The shape and size of the housing can significantly affect the boost pressure generated by the turbocharger. A well-designed housing will optimize the flow path, enhancing the efficiency of the turbocharger and allowing for quicker spool-up times. This means the engine can reach its optimal performance level faster, providing a more responsive driving experience.

Moreover, advancements in technology have led to the development of variable geometry turbochargers (VGTs), which feature adjustable vanes within the compressor housing. This innovation enables better control of the boost at various engine speeds, improving both power delivery and fuel efficiency.

In conclusion, the turbo compressor housing is an integral part of the turbocharging system, contributing significantly to performance and efficiency. Its design and materials must meet the rigorous demands of high-speed operation, and modifications can lead to enhanced vehicle dynamics. As automotive technology continues to evolve, the importance of optimizing turbo compressor housings remains paramount for achieving high-performance engines.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025