Mobile:+86-311-808-126-83

Email:info@ydcastings.com

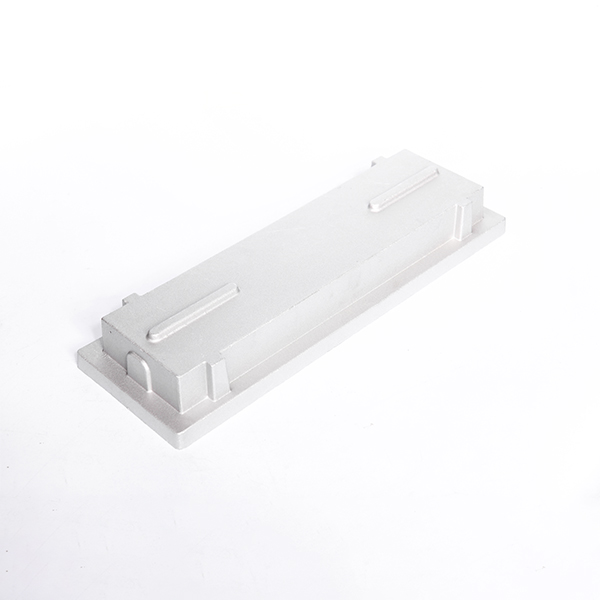

turbine impeller types

Understanding Turbine Impeller Types A Comprehensive Guide

Turbine impellers are critical components in various applications including power generation, marine propulsion, and industrial processes. Their design and functionality can significantly affect the performance, efficiency, and reliability of a turbine system. Through a clear understanding of the different types of turbine impellers, engineers and technicians can select the appropriate design for their specific needs. In this article, we will explore the most common types of turbine impellers, their characteristics, advantages, and ideal applications.

1. Radial Impellers

Radial impellers are one of the most commonly used types in various turbine applications. They operate by drawing fluid into the center and expelling it radially outward. This configuration delivers high pressure and is particularly effective in applications where a significant increase in pressure is required. Radial impellers are often used in pump systems where high flow rates are essential, such as in hydroelectric plants and certain types of jet engines.

Advantages - High efficiency in converting mechanical energy into hydraulic energy. - Capability of handling large volumes of fluid. - Excellent performance in high-pressure applications.

Applications - Water pumps - Hydroelectric turbines - Centrifugal compressors

Axial impellers, as the name suggests, direct the flow of fluid in an axial direction, meaning parallel to the axis of the impeller shaft. These impellers generate low pressure but high flow rates, making them ideal for applications where a moderate increase in pressure is sufficient.

Advantages - Higher flow rates compared to radial designs. - More compact in design, requiring less space. - Better suited for low-viscosity fluids.

Applications - Aircraft engines - Marine propulsion systems - Wind turbines

turbine impeller types

3. Mixed-Flow Impellers

Mixed-flow impellers combine the principles of both radial and axial designs. They can handle fluids in both radial and axial directions, providing a versatile option that utilizes the strengths of both types. These impellers are designed to provide medium pressure increases and moderate flow rates, which makes them suitable for a range of applications.

Advantages - Balanced performance with medium pressure and flow rates. - Versatility in handling various fluids and conditions. - Good efficiency for a range of operational conditions.

Applications - Turbomachinery - Chemical processing - HVAC systems

4. Adjustable Impellers

Adjustable impellers offer dynamic performance capabilities, allowing the user to modify the pitch or angle of the blades. This feature enables real-time adjustments to optimize efficiency and performance based on changing operational conditions. This flexibility can be particularly beneficial in applications where load or flow conditions frequently change.

Advantages - Ability to optimize performance based on current conditions. - Enhanced efficiency in fluctuating operational contexts. - Potential energy savings over traditional fixed designs.

Applications - Variable-speed pumps - Power plants with fluctuating loads - Advanced industrial processes

Conclusion

Choosing the right type of turbine impeller is crucial for optimizing system performance. By understanding the different types—radial, axial, mixed-flow, and adjustable—engineers can make informed decisions that enhance efficiency and operational effectiveness. The selection process should consider the specific requirements of each application, including the nature and viscosity of the fluid being handled, the desired pressure and flow rate, and any operational constraints. By leveraging the strengths of each impeller type, industries can achieve reliable and efficient turbine performance, thereby maximizing productivity and minimizing operational costs. The ongoing advancements in impeller technology continue to push the boundaries of performance, making it an exciting field for future exploration.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025