Mobile:+86-311-808-126-83

Email:info@ydcastings.com

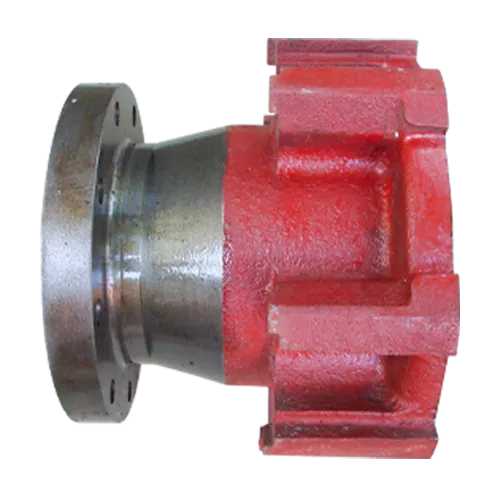

Types of Turbine Impellers and Their Applications in Engineering

Understanding Turbine Impeller Types

Turbine impellers are critical components in various engineering applications, particularly in the fields of aerospace, automotive, and power generation. These components are designed to convert fluid energy into mechanical energy, facilitating the efficient operation of turbines. The selection of an appropriate turbine impeller type is essential for optimizing performance and ensuring reliability. In this article, we will explore the different types of turbine impellers, their characteristics, and suitable applications.

1. Radial Impellers

Radial impellers are one of the most common types used in centrifugal pumps and turbines. They are designed such that the fluid flows radially outward or inward from the center of the impeller. The main characteristic of radial impellers is their ability to generate high pressure and moderate flow rates. This design makes them ideal for applications requiring consistent and high-pressure output, such as water supply systems and industrial processes.

Radial impellers can be further categorized into closed, semi-closed, and open configurations. Closed impellers feature two shrouds, which improve efficiency and reduce the risk of cavitation. Semi-closed impellers have one shroud and are suitable for fluids with solids or contaminants, while open impellers have no shrouds and are used in applications where flow conditions vary widely.

Mixed flow impellers combine characteristics of both radial and axial flow designs. In mixed flow turbines, the fluid moves both radially and axially. This unique design allows mixed flow impellers to handle a wide range of flow rates and pressures more effectively than purely radial or axial designs. Due to their versatile performance, mixed flow impellers are often used in applications such as wastewater treatment plants and irrigation systems.

The mixed flow design also allows for smaller and lighter turbine setups, enabling more compact machinery in various installations. However, engineers need to consider specific flow conditions to optimize the impeller design for a particular application.

turbine impeller types

3. Axial Flow Impellers

Axial flow impellers enable fluid to flow parallel to the axis of rotation. These impellers are particularly efficient at moving large volumes of fluid at lower pressures, making them ideal for applications like ventilation systems and cooling towers. Axial flow impellers can dissipate energy with less turbulence, contributing to their higher efficiency in specific scenarios.

Another advantage of axial flow impellers is their capability to handle varying fluid levels. In environments where the flow may fluctuate, these impellers can adapt more readily, maintaining consistent performance.

4. Turbine Impeller Materials

The choice of material is also critical when selecting turbine impellers. Common materials include stainless steel, aluminum, and various high-performance polymers. Stainless steel offers superior strength and corrosion resistance, making it suitable for harsh environments. Meanwhile, aluminum provides a lightweight alternative for applications where weight is a concern, such as in aerospace. High-performance polymers can withstand harsh chemicals and environments, providing specialized solutions for specific industries.

Conclusion

In conclusion, understanding the various types of turbine impellers—radial, mixed flow, and axial—is essential for engineers and designers in many fields. Each impeller type presents unique benefits and challenges, making it crucial to align the right design with specific operational requirements. As technology advances, innovations in turbine impeller design continue to improve their efficiency and reliability, paving the way for enhanced performance in energy production, fluid management, and various industrial applications. By selecting the appropriate turbine impeller, industries can ensure optimal performance while minimizing energy consumption and operational costs.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025