Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Optimizing Turbocharger Performance Through Advanced Turbine Housing Design Techniques

Understanding Turbocharger Turbine Housing

Turbochargers have become an integral component in modern automotive engineering, playing a pivotal role in enhancing engine performance and efficiency. At the heart of a turbocharger lies the turbine housing, a crucial element that significantly influences the overall functionality of the unit.

Understanding Turbocharger Turbine Housing

One of the key factors in turbine housing design is the materials used. Typically, the housing is made from cast iron or stainless steel, chosen for their ability to withstand high temperatures and resist thermal fatigue. Stainless steel is often preferred in high-performance applications due to its superior heat resistance and lower thermal expansion properties, which help to maintain the turbocharger’s structural integrity under extreme conditions.

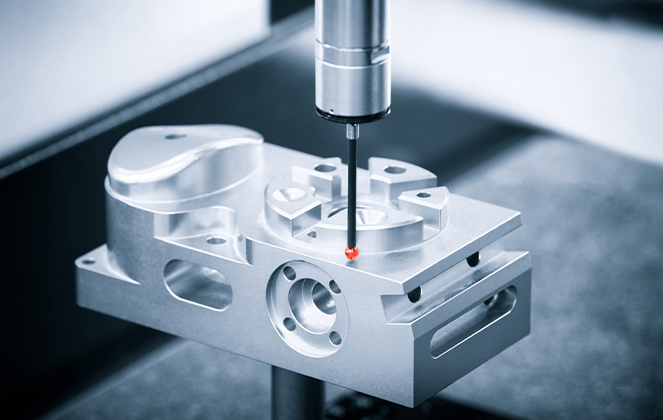

turbine housing turbocharger

The configuration of the turbine housing also has significant implications on performance. The design must balance multiple parameters such as flow characteristics, pressure drop, and response time. A common design consideration is the size and shape of the inlet and outlet ports. A larger inlet can facilitate quicker exhaust flow into the turbine, improving response times, while the shape of the outlet can impact back pressure and the overall efficiency of the turbocharger.

Another important aspect is the A/R ratio, which refers to the area-to-radius ratio of the turbine housing. A lower A/R ratio typically allows for quicker spool-up times, which is beneficial in applications requiring rapid acceleration, while a higher A/R ratio can lead to higher top-end power, making it suitable for performance-tuned engines. This choice can significantly affect the engine's character, leading to trade-offs that engineers must consider during the design phase.

Additionally, advancements in technology have introduced variable geometry turbine (VGT) housings, which offer further refinements in performance. VGTs can adjust their geometry based on engine demand, optimizing the flow of exhaust gases and improving turbo response across a wider range of engine speeds. This technology represents a step forward in achieving more responsive power delivery and enhanced efficiency.

In summary, the turbine housing of a turbocharger is a complex component that plays a critical role in determining the efficiency, performance, and responsiveness of a turbocharged engine. The materials used, the configuration of the housing, the A/R ratio, and the adoption of advanced technologies such as variable geometry all contribute to the effectiveness of the turbocharger. As automotive technology continues to evolve, the importance of refining the design and functionality of turbine housings will remain paramount in the quest for better engine performance and greater fuel efficiency. Understanding these factors is essential for anyone interested in the future of automotive engineering and performance tuning.