Mobile:+86-311-808-126-83

Email:info@ydcastings.com

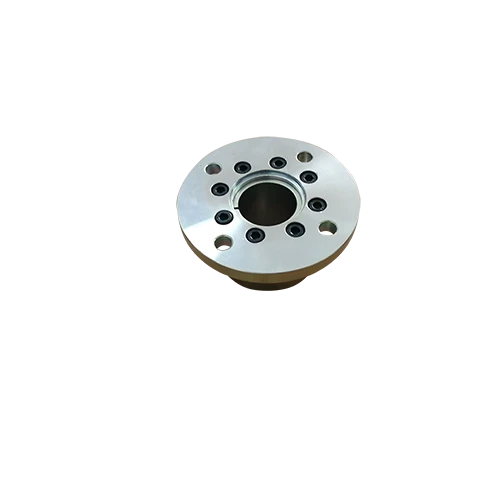

turbine housing

Understanding Turbine Housing Function, Design, and Materials

Turbine housing is a crucial component in various engineering applications, particularly in the fields of aviation, power generation, and automotive engineering. It serves as a protective enclosure for the turbine, which is responsible for converting kinetic energy from fluid flow into mechanical energy. This article delves into the function, design considerations, and materials used in turbine housings to provide a comprehensive understanding of their significance.

Function of Turbine Housing

The primary function of turbine housing is to encapsulate the turbine while providing structural support and protection. It shields the internal components from environmental factors such as dust, moisture, and corrosive elements. Additionally, turbine housing aids in directing the flow of gases or fluids into the turbine, optimizing efficiency and performance.

In gas turbine engines, the housing plays a vital role in managing the high temperatures and pressures generated during operation. It must maintain integrity under extreme conditions, as failure could result in catastrophic consequences. The housing also contains various systems for cooling and lubrication, which are essential for the smooth operation of the turbine.

Design Considerations

Designing turbine housing involves multiple considerations that affect performance, reliability, and manufacturability

. One of the key aspects is aerodynamics; the housing must be shaped to facilitate optimal airflow into the turbine without inducing turbulence that could hinder efficiency.The size and weight of the housing are also critical factors. In aerospace applications, for example, minimizing weight is essential for improving fuel efficiency and overall aircraft performance. Consequently, engineers often employ advanced computational fluid dynamics (CFD) simulations to optimize the design before moving to physical prototypes.

turbine housing

Thermal management is another vital consideration. Turbines operate at high temperatures, and the material selection for the housing must account for thermal expansion, resistance to heat, and the ability to dissipate heat effectively. The design may incorporate features such as cooling passages or external fins to enhance thermal performance.

Materials Used in Turbine Housing

The materials used for turbine housing must meet specific criteria, including strength, heat resistance, and corrosion resistance. Common materials include metals like aluminum, titanium, and various high-strength alloys. Each material has its advantages and trade-offs. For instance, aluminum is lightweight and has good thermal conductivity, making it ideal for applications where weight savings are paramount. However, it may not possess the same thermal resistance as nickel-based superalloys, which are often used in high-performance gas turbines.

Composite materials are also becoming increasingly popular in turbine housing design, particularly in aerospace applications. Composites can offer a high strength-to-weight ratio and excellent corrosion resistance, while also allowing for more intricate shapes than traditional metals. However, the challenge lies in ensuring compatibility with other materials and the complexities of manufacturing.

Future Trends

As technology advances, the design and materials used in turbine housing are expected to evolve. Innovations in additive manufacturing (3D printing) are paving the way for more complex and optimized designs that traditional manufacturing techniques might struggle to achieve. Furthermore, the push for more sustainable energy sources is prompting research into novel materials that can withstand the demanding conditions of renewable energy applications, such as wind turbines.

In conclusion, turbine housing is an integral part of turbine technology, balancing the need for structural integrity with aerodynamic efficiency and thermal management. As engineers continue to refine turbine housing designs and materials, we can expect improved performance and reliability across various applications, ultimately contributing to advancements in energy production and aerospace technologies.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025