Mobile:+86-311-808-126-83

Email:info@ydcastings.com

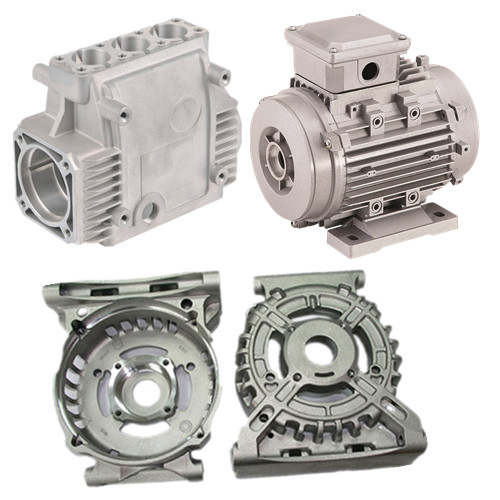

tp38 compressor housing

The Significance and Design Considerations of TP38% Compressor Housing

In the realm of mechanical engineering, particularly in the context of turbocharging systems, the compressor housing plays a pivotal role. Focusing on the TP38% compressor housing, we uncover its design intricacies, performance capabilities, and overall importance in optimizing the efficiency of internal combustion engines.

Understanding Compressor Housing

The compressor housing serves as the outer shell that encloses the compressor wheel within a turbocharger. Its primary function is to direct the airflow from the outside into the compressor wheel and subsequently to the engine's intake. The effectiveness of the housing directly influences the turbocharger's efficiency, responsiveness, and durability. The TP designation typically refers to the specific model or configuration, while 38% encapsulates parameters linked to its efficiency curve or operational capacity.

Design Features of TP38% Compressor Housing

The design of the TP38% compressor housing incorporates advanced computational fluid dynamics (CFD) to enhance airflow characteristics. Key features include a streamlined inlet with optimized contours to minimize turbulence and maximize airflow velocity. The housing is often crafted from high-grade materials such as aluminum or cast iron, ensuring it can withstand both heat and pressure during operation.

Moreover, the housing is designed with carefully calculated volute geometry. A well-engineered volute helps in evenly distributing airflow around the compressor wheel, reducing pressure losses and increasing performance. The size and shape of the compressor exit also play a significant role in achieving the desired boost pressure and efficiency, making it a crucial aspect of the housing's design.

Performance Benefits

tp38 compressor housing

One of the primary advantages of the TP38% compressor housing is its ability to achieve a higher compression ratio. This characteristic leads to better performance in terms of power output and throttle response. By optimizing the intake airflow, the housing allows for a denser air charge to enter the engine, leading to a significant increase in combustion efficiency.

Additionally, the TP38% compressor housing is known for its ability to reduce turbo lag, thanks to its design that facilitates quick spool-up times. This means drivers experience improved acceleration and power delivery, enhancing the overall driving experience.

Durability and Maintenance

Durability is another crucial aspect of compressor housing design. Due to the high temperatures and pressures encountered in turbocharger systems, the materials used must withstand constant thermal cycling and mechanical stress. Properly designed TP38% compressor housings are resistant to fatigue and corrosion, ensuring a long service life and reliable performance.

Regular maintenance is essential to keep the compressor housing functioning optimally. This includes routine inspections for signs of wear, as well as ensuring proper lubrication of bearings and seals. Maintaining the integrity of the compressor housing is vital, as any leaks or damage can lead to significant drops in performance and potential engine damage.

Conclusion

In summary, the TP38% compressor housing is an integral component of turbocharger systems that significantly enhances engine performance. By focusing on aerodynamic design, material durability, and maintenance, manufacturers have developed a housing that not only improves efficiency but also prolongs engine life. As automotive technology continues to evolve, innovations in compressor housing design will pave the way for even more powerful and efficient engines, making the TP38% a noteworthy consideration for both manufacturers and performance enthusiasts alike. The interplay between design and functionality within the compressor housing underscores its importance in the broader context of automotive engineering, shaping the future of performance-driven vehicles.

-

Understanding Metal Casting TechniquesNewsApr.02,2025

-

Understanding Exhaust Manifolds for Enhanced Engine PerformanceNewsApr.02,2025

-

The World of Metal FabricationNewsApr.02,2025

-

Key Components for Pump and Turbo EfficiencyNewsApr.02,2025

-

Essential Tools for Automotive Maintenance and RepairNewsApr.02,2025

-

Durable Valve Components for Effective Water ManagementNewsApr.02,2025