Mobile:+86-311-808-126-83

Email:info@ydcastings.com

steel investment casting company

Steel Investment Casting Transforming Ideas into Durable Solutions

In the realm of manufacturing, investment casting has emerged as a superior method for producing intricate and precise metal components. Among various materials used in investment casting, steel stands out due to its exceptional strength, durability, and versatility. Steel investment casting companies are instrumental in turning conceptual designs into tangible products, catering to diverse industries such as aerospace, automotive, medical, and construction.

What is Steel Investment Casting?

Steel investment casting, also known as lost-wax casting, is a process that involves creating a wax pattern of the desired component, which is then coated with a ceramic material to form a mold. Once the mold is set, the wax is melted away, leaving a hollow shell. Molten steel is poured into this mold, allowing it to take the shape of the pattern. After cooling, the mold is broken away to reveal a finely detailed steel component.

This method is favored for its ability to produce complex geometries and tight tolerances that traditional casting methods may struggle to achieve. Steel investment casting is particularly advantageous for parts that require high strength-to-weight ratios and resistance to wear and corrosion.

Advantages of Steel Investment Casting

1. Precision and Complexity One of the most significant benefits of steel investment casting is its ability to create intricate designs with high precision. The lost-wax technique allows for fine details, which is particularly important in industries requiring complex geometries.

2. Material Versatility Steel investment casting can utilize various types of steel, including carbon steel, alloy steel, and stainless steel. This versatility enables manufacturers to tailor their products to meet specific performance requirements.

3. Reduced Waste Unlike traditional machining, which often results in a substantial amount of wasted material, steel investment casting is an efficient process that minimizes scrap. The precision of the casting reduces the need for extensive post-processing, yielding a more sustainable manufacturing approach.

steel investment casting company

4. Cost-Effectiveness for Large Productions While the initial setup costs for investment casting can be higher than other methods, the overall cost becomes competitive when producing large quantities. The ability to produce multiple parts at once and the reduction in machining costs contribute to its economic viability.

Applications of Steel Investment Casting

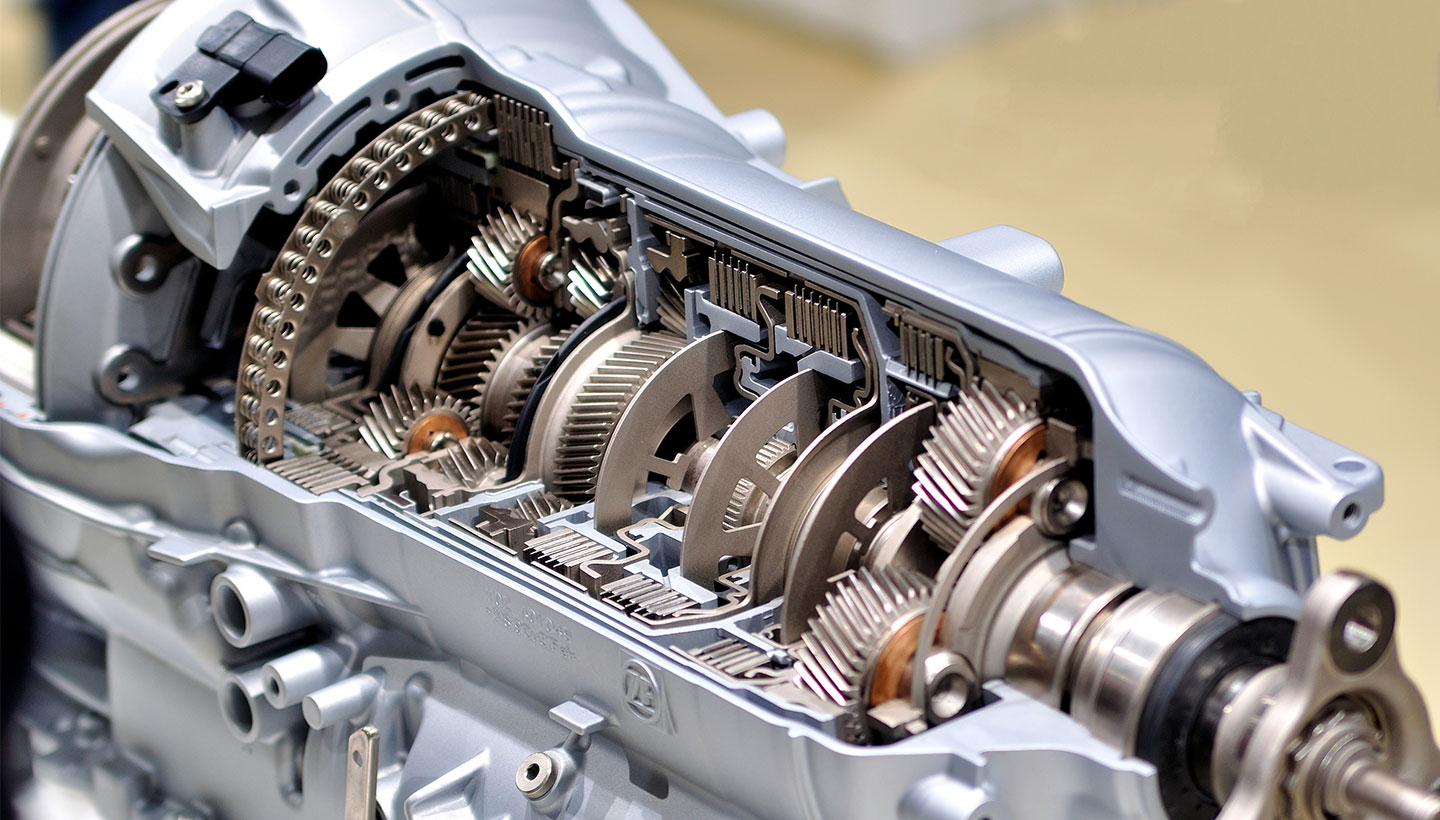

The applications of steel investment casting are vast and varied. In the aerospace industry, components such as turbine blades, landing gear, and structural parts are often produced using this method to ensure strength and reliability. Similarly, the automotive sector benefits from investment casting for producing engine components, transmission parts, and various structural elements designed for performance and safety.

In the medical field, precision-cast steel components are essential for surgical instruments and implants, where reliability and biocompatibility are paramount. Furthermore, the construction industry utilizes steel investment castings for hardware, brackets, and other components that require durability and resistance to environmental stressors.

The Future of Steel Investment Casting

As technology advances, the steel investment casting industry continues to evolve. Innovations such as computer-aided design (CAD) and 3D printing are being integrated into the casting process, enhancing design capabilities and production efficiency. These advancements not only improve the accuracy of complex designs but also shorten lead times, making it easier for companies to respond to market demands swiftly.

Moreover, as sustainability becomes a priority across industries, investment casting companies are exploring eco-friendly materials and practices. The adoption of recycled steel and energy-efficient processes reflects a growing commitment to environmentally responsible manufacturing.

Conclusion

Steel investment casting companies are at the forefront of modern manufacturing, transforming innovative designs into durable and reliable components. With unmatched precision, versatility, and efficiency, this casting method serves a myriad of industries, meeting the demands of a rapidly evolving market. As technology continues to advance, steel investment casting will undoubtedly play a crucial role in shaping the future of manufacturing, delivering high-quality solutions to complex challenges.

-

Understanding Metal Casting TechniquesNewsApr.02,2025

-

Understanding Exhaust Manifolds for Enhanced Engine PerformanceNewsApr.02,2025

-

The World of Metal FabricationNewsApr.02,2025

-

Key Components for Pump and Turbo EfficiencyNewsApr.02,2025

-

Essential Tools for Automotive Maintenance and RepairNewsApr.02,2025

-

Durable Valve Components for Effective Water ManagementNewsApr.02,2025