Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Innovative Techniques in Stainless Steel Investment Casting for Enhanced Product Quality

The Benefits and Advantages of Investment Casting in the SS Industry

Investment casting, also known as lost-wax casting, is a highly versatile manufacturing process utilized in various industries ranging from aerospace to automotive. Among its many applications, investment casting has proven to be particularly beneficial in producing stainless steel (SS) components. This article explores the advantages of investment casting in the context of stainless steel manufacturing, highlighting its precision, material efficiency, and overall cost-effectiveness.

One of the primary advantages of investment casting is its ability to produce components with intricate geometries and tight tolerances. This process employs a pattern made of wax or other materials, which is coated in a ceramic substance to create a mold. Once the mold is formed, the wax is melted away, leaving a cavity in the desired shape. For stainless steel parts, this method allows for detailed features that may be impossible or cost-prohibitive to achieve using traditional machining techniques. The result is a component that not only meets the tight specifications required by industries but also reflects an aesthetically pleasing finish due to the smooth surface of the cast.

The Benefits and Advantages of Investment Casting in the SS Industry

In addition to precision and efficiency, investment casting also offers versatility in terms of the range of stainless steel alloys that can be used. Stainless steel is chosen for its excellent corrosion resistance, strength, and durability, making it suitable for a vast array of applications. Investment casting allows manufacturers to utilize various stainless steel grades, ensuring that the final products possess the necessary properties to withstand extreme environments. For example, austenitic stainless steels are favored in food processing and chemical applications due to their non-reactive nature, while martensitic stainless steels are chosen for applications requiring high strength and hardness.

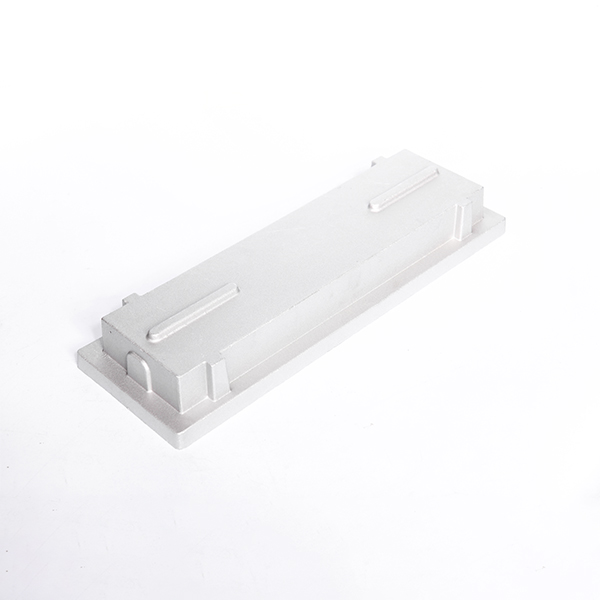

ss investment casting

Cost-effectiveness is another significant advantage of investment casting. While the initial setup costs for investment casting may be higher than some other methods, the long-term savings achieved through reduced material waste, labor costs, and the elimination of additional machining processes can outweigh these initial investments. Additionally, the scalability of the investment casting process makes it suitable for both small-scale production runs and large mass productions, giving businesses the flexibility to meet varying demands without incurring prohibitive costs.

Furthermore, the investment casting technique has the potential to enhance the overall lead time from concept to production, particularly when compared to traditional manufacturing processes. This can lead to faster product development cycles, allowing companies to respond more rapidly to market demands and technological advancements. In a fast-paced environment where timely delivery of components is crucial, investment casting stands out as a viable solution.

Finally, investment casting facilitates a clean and controlled manufacturing environment. The process generates less noise and produces fewer airborne contaminants compared to other metalworking methods. This creates a safer workplace for operators and contributes to better compliance with regulatory standards regarding environmental impacts.

In conclusion, investment casting is a highly effective method for producing stainless steel components, offering unique advantages such as precision, material efficiency, and cost-effectiveness. Its versatility in accommodating various stainless steel grades further extends its appeal across industries. As demand for high-quality, intricate stainless steel parts continues to grow, investment casting will likely remain a key production method, driving innovation and excellence in manufacturing.

-

Impeller Technology That Powers Precision in Pump SystemsNewsMay.22,2025

-

Valve Durability Begins with Quality Cast Iron ComponentsNewsMay.22,2025

-

Performance Cooling with Advanced Automobile Water Pump SolutionsNewsMay.22,2025

-

How Motor Housing and Oil Pans Shape Engine PerformanceNewsMay.22,2025

-

How Metal Castings Drive Modern Manufacturing EfficiencyNewsMay.22,2025

-

Exploring the Engineering Behind Valve Body CastingsNewsMay.22,2025