Mobile:+86-311-808-126-83

Email:info@ydcastings.com

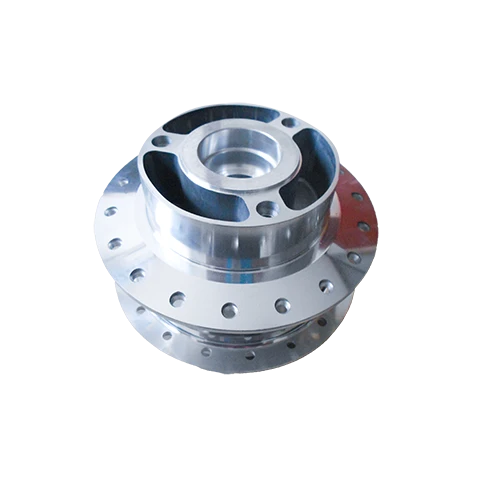

slurry pump impeller

Understanding Slurry Pump Impellers A Key Component in Material Handling

Slurry pumps are essential machinery in various industries, including mining, wastewater treatment, and chemical processing. At the core of a slurry pump's operation is the impeller, a critical component designed for moving abrasive and viscous mixtures of solids and liquids. This article delves into the role of impellers in slurry pumps, their design considerations, and the impact they have on operational efficiency.

The Role of Impellers in Slurry Pumps

The impeller in a slurry pump is responsible for converting rotational energy, typically provided by an electric motor, into hydraulic energy. As the impeller spins, it creates centrifugal force that pushes the slurry outward from the center of the pump casing. This action creates a vacuum at the impeller hub, allowing more slurry to be drawn into the pump. The effectively designed impeller is crucial in ensuring that the slurry is pumped efficiently without causing excessive wear on the pump components.

Design Considerations

When designing a slurry pump impeller, several key factors must be considered

slurry pump impeller

1. Material Selection Slurry pumps often handle abrasive and corrosive materials, necessitating the use of robust materials such as high-chrome alloys, rubber, or polyurethane. The choice of material directly affects the impeller's lifespan and pump efficiency.

2. Impeller Geometry The shape and size of the impeller blades significantly influence the pump's performance. Impellers can be classified as open, semi-open, or closed designs. Each design has its advantages depending on the specific application's needs. For example, open impellers are less prone to clogging but may have lower efficiency compared to closed designs.

3. Clearance Settings The space between the impeller and the pump casing, often referred to as the clearance, should be optimized to prevent the loss of hydraulic energy. Too much clearance can lead to reduced efficiency and increased vibration, while too little can cause wear and overheating.

Impact on Operational Efficiency

The efficiency of a slurry pump is heavily dependent on the design and quality of the impeller. An efficient impeller minimizes energy consumption while maximizing flow rate and pressure, which is crucial for maintaining optimal operations in process industries. Poorly designed or worn impellers can lead to increased operational costs, frequent maintenance, and downtime.

In conclusion, the impeller is a vital component in slurry pumps that plays a significant role in their performance and longevity. By understanding the various design considerations and their impact on efficiency, industries can select the right slurry pump and impeller configuration to meet their specific needs. This knowledge not only enhances productivity but also contributes to the overall stability and reliability of material handling processes.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025