Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Design and Development of a Housing for Servo Motors in Robotics Applications

Understanding Servo Motor Housing The Unsung Hero of Precision Engineering

Servo motors have become an indispensable part of modern engineering, robotics, and automation. They are essential components in applications where precise control of angular or linear position, velocity, and acceleration is required. While the intricacies of servo motors themselves are often discussed, less attention is given to their housing—a critical element that undertakes several essential roles in ensuring the reliable operation of servo motors.

What is Servo Motor Housing?

The servo motor housing is the protective outer shell that encases the internal components of a servo motor. It is typically made from materials such as aluminum, steel, or high-strength plastic. The design and material of the housing are crucial as they must not only protect the internal components from environmental factors but also ensure the motor's performance under various operational conditions.

Key Functions of Servo Motor Housing

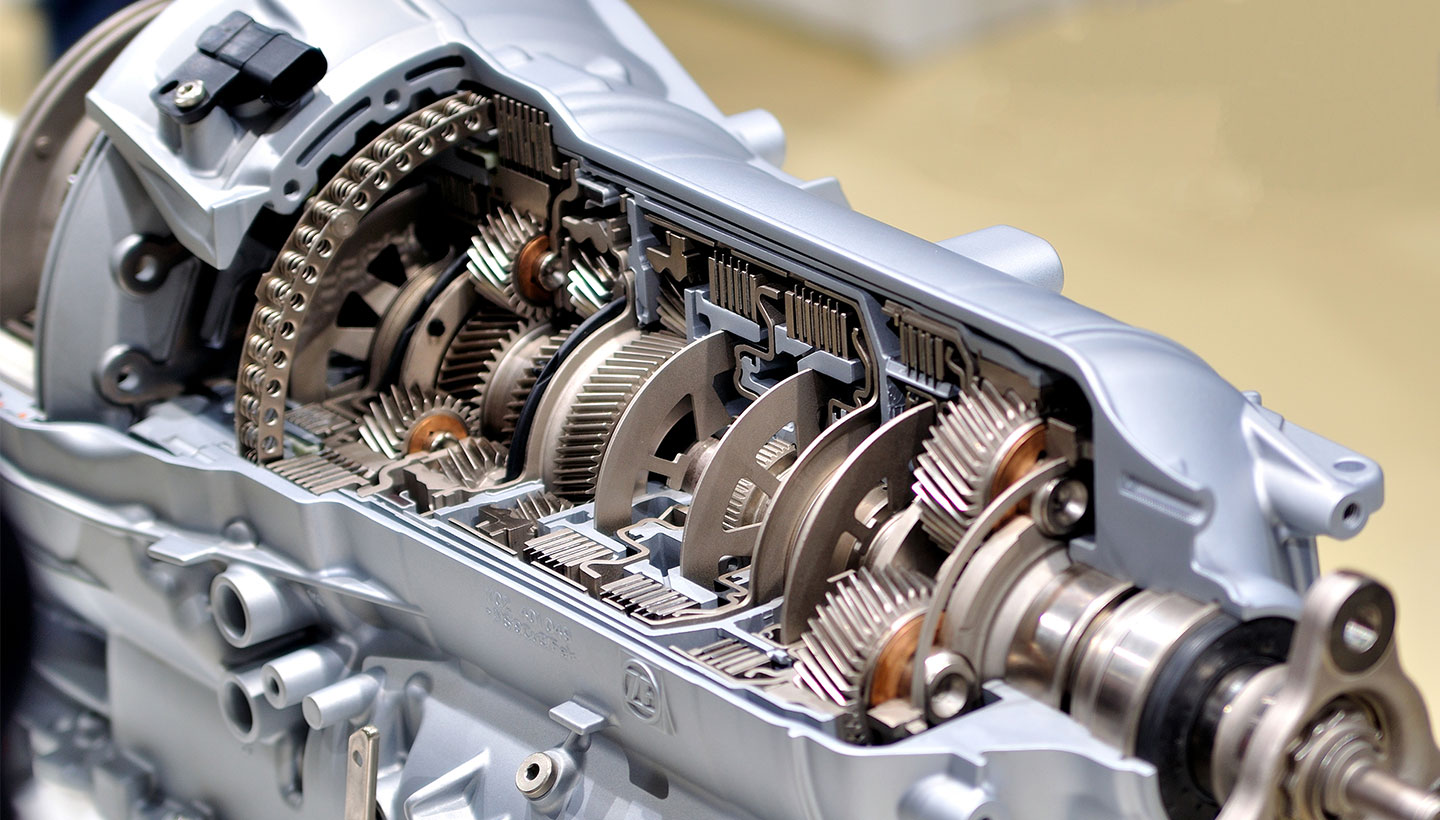

1. Protection One of the primary purposes of the housing is to protect the internal mechanisms, including gears, brushes, and electronic circuits, from dust, dirt, moisture, and other contaminants. Depending on the application, servo motors might operate in harsh environments such as factories, outdoors, or in damp conditions, making durable housing vital.

2. Structural Integrity The housing ensures that the internal components are held securely in place. This structural integrity is crucial as it allows the servo motor to withstand vibrations, shocks, and the physical stresses that arise during operation. A robust housing prevents misalignment, which could result in performance degradation or complete failure of the motor.

3. Thermal Management Servo motors generate heat during operation, and effective thermal management is essential for maintaining optimal performance. The housing can be designed to dissipate heat efficiently, either through passive convection, radiation, or active cooling methods. Proper heat management helps to prolong the life of the motor and maintains its operation within specified temperature limits.

servo motor housing

4. Electrical Isolation The housing also provides essential electrical insulation, preventing short circuits and ensuring safety. By housing sensitive electronic components in a non-conductive enclosure, the risk of electrical failure is minimized, which is crucial in protecting both the motor and the wider system it operates within.

5. Integration with Other Systems The design of servo motor housings can also facilitate the integration of additional components, such as connectors, mounting brackets, and other accessories. This integration ensures that the servo motor can easily be incorporated into a larger assembly or system, aiding in versatility across various applications.

Design Considerations

When designing servo motor housing, engineers must consider several factors. The choice of material is essential, balancing weight and strength, while also considering cost. Additionally, the dimensions of the housing must align with the specific application requirements, ensuring compatibility with existing systems.

Furthermore, the housing design must account for the intended environment—whether that be high temperatures, exposure to chemicals, or underwater applications. Advanced modeling and simulations can help predict how different designs will perform under varying conditions, informing the best housing choices for a given servo motor application.

Conclusion

While often overlooked, the housing of a servo motor plays a pivotal role in its performance, reliability, and longevity. As industries continue to push the boundaries of automation and robotic applications, understanding the significance of servo motor housing becomes increasingly important. Engineers must not only prioritize the functionality and efficiency of servo motors but also give due consideration to their protective and supporting structures. Through innovative design and material choices, the humble servo motor housing can significantly impact the success of a wide array of technological applications, underscoring its status as an unsung hero of precision engineering.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025