Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Innovative Design of Sawtooth Impeller for Enhanced Fluid Mixing Performance

The Sawtooth Impeller A Key Component in Fluid Dynamics

The sawtooth impeller is a specialized type of mixing device widely used in various industrial applications, particularly in fluid dynamics. Its unique design, characterized by its serrated edges resembling a sawtooth pattern, facilitates efficient mixing and blending of liquids, solids, and slurries. This article explores the essential features, advantages, applications, and operational principles of the sawtooth impeller.

Design Features

The sawtooth impeller’s design enhances its performance, making it ideal for applications that require high shear and turbulent mixing. The sawtooth edges create vortices within the fluid, promoting a more uniform distribution of particles and enabling the breakdown of agglomerates. This design allows for both axial and radial flow, providing versatility in handling varying operational conditions. Availability in multiple sizes and materials also ensures that the impeller can be tailored to meet specific process requirements.

Advantages of Sawtooth Impellers

One of the primary advantages of sawtooth impellers is their ability to achieve higher shear rates compared to traditional impellers. This feature is crucial for processes such as emulsification, dispersing, and homogenization, where fine mixing is necessary. The enhanced mixing action reduces the time required for processes, leading to improved efficiency and productivity. Additionally, the sawtooth design minimizes dead zones within the mixing vessel, ensuring consistent and thorough mixing throughout the entire volume of the fluid.

Another significant benefit is the reduction in energy consumption. Traditional impellers often require higher rotational speeds to achieve adequate mixing, which can lead to excessive energy usage and operational costs. In contrast, the sawtooth impeller can achieve similar or superior mixing results at lower speeds, making it a more energy-efficient solution.

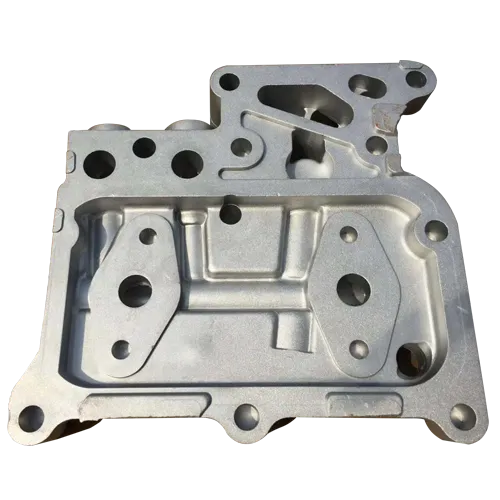

sawtooth impeller

Applications

Sawtooth impellers are utilized in a broad range of industries due to their effectiveness in improving mixing processes. In the chemical manufacturing industry, they are employed to mix complex chemical formulations, ensuring homogeneity and consistency in product quality. The pharmaceutical sector also relies on sawtooth impellers for the preparation of suspensions and emulsions, where precise control over particle size and distribution is critical.

In the food and beverage industry, these impellers find application in blending and homogenizing ingredients. The dairy industry, for instance, benefits from their ability to achieve the desired texture and consistency in products like yogurt and cream. Additionally, they are used in wastewater treatment plants to facilitate the mixing of chemicals and sludge, enhancing the efficiency of the treatment process.

Operational Principles

The effectiveness of the sawtooth impeller is largely attributed to its operational principles. As the impeller rotates, the sawtooth edges impart kinetic energy to the fluid, resulting in high-velocity flow patterns. This action creates shear forces that break down large particles and distribute them evenly throughout the mixture. The continuous motion also ensures that the fluid remains in a turbulent state, further enhancing the mixing process.

In conclusion, the sawtooth impeller is an indispensable tool in fluid dynamics, offering significant advantages in terms of mixing efficiency, energy consumption, and versatility across various industries. Its unique design and operational principles make it a preferred choice for applications requiring precise and effective mixing. As industries continue to evolve, the demand for advanced mixing technologies, such as sawtooth impellers, is expected to grow, driving innovation and improved processes in numerous fields.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025