Mobile:+86-311-808-126-83

Email:info@ydcastings.com

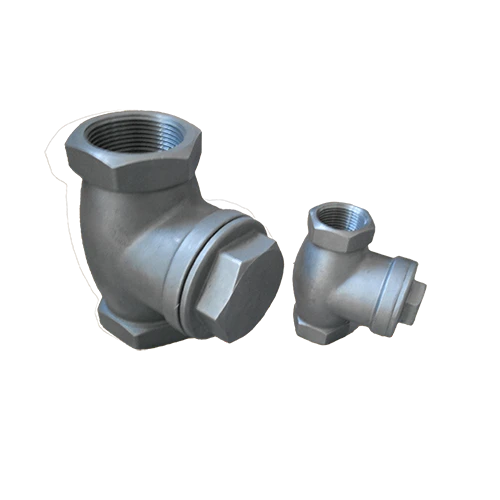

press mold metal

Understanding Press Mold Metal A Key Component in Modern Manufacturing

In the realm of modern manufacturing, efficiency and precision are paramount. One of the key technologies enabling these qualities is the process of press mold metal. This technique has revolutionized the way we produce metal components, making it possible to achieve intricate designs with high accuracy while significantly reducing production time. In this article, we will explore what press mold metal is, its benefits, applications, and future prospects.

What is Press Mold Metal?

Press mold metal, often referred to as metal stamping or metal pressing, involves the use of a mechanical press to shape or cut metal sheets into specific forms. This process can be divided into two main categories blanking and embossing. In blanking, sections are cut from large metal sheets to create flat components, while embossing involves creating raised or recessed designs on the surface of the metal.

The press itself can operate using mechanical or hydraulic systems, which apply immense pressure to mold the metal into the desired shape. The choice between mechanical and hydraulic methods often depends on the specific requirements of the project, including the thickness of the metal, the complexity of the design, and desired production volume.

Advantages of Press Mold Metal

One of the most significant advantages of press mold metal is its efficiency. The ability to produce large quantities of parts quickly through automation ensures that manufacturers can meet high demand without compromising on quality. Additionally, the precision of this process allows for minimal material wastage, making it a cost-effective solution for mass production.

Another significant benefit is the versatility of the technique. Press mold metal can be used to create a vast array of products, from simple components to complex assemblies. Industries ranging from automotive and aerospace to electronics and home appliances rely heavily on this technology. The ability to work with various types of metals, including steel, aluminum, and copper, further enhances the usability of press mold metal in diverse applications.

Furthermore, advancements in technology have led to the development of computer-aided design (CAD) and computer-aided manufacturing (CAM) systems. These innovations allow for more complex designs and quicker prototyping, making it easier for manufacturers to innovate and adapt their products according to market demands.

press mold metal

Applications Across Industries

The applications of press mold metal are extensive and varied. In the automotive industry, for example, it is commonly used to produce parts such as brackets, panels, and structural components. These parts must adhere to strict safety and reliability standards, which the press mold metal process is well-suited to meet.

In electronics, press mold metal is essential for creating housings, connectors, and circuit components that require high precision and durability. Similarly, in the aerospace sector, this technique plays a critical role in producing lightweight yet strong structural parts that are essential for aircraft performance and safety.

The Future of Press Mold Metal

As technology continues to evolve, so too will the applications and techniques associated with press mold metal. The integration of artificial intelligence (AI) and machine learning into manufacturing processes promises to enhance efficiency even further. These technologies can optimize workflows, predict maintenance needs, and analyze production data, leading to smarter manufacturing environments.

Additionally, the drive towards sustainability will likely influence future developments in press mold metal. Manufacturers are increasingly seeking ways to reduce their carbon footprint, and innovations in materials and processes will play a crucial role in achieving this goal. The adoption of recycled metals and the implementation of eco-friendly practices are trends that may shape the future landscape of press mold metal manufacturing.

Conclusion

Press mold metal is an indispensable process in modern manufacturing, offering unmatched efficiency, precision, and versatility. Its applications span numerous industries, fueling innovation and productivity. As we move forward, the integration of advanced technologies and sustainable practices will further enhance the capabilities of press mold metal, ensuring that it remains a cornerstone of effective manufacturing for years to come.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025