Mobile:+86-311-808-126-83

Email:info@ydcastings.com

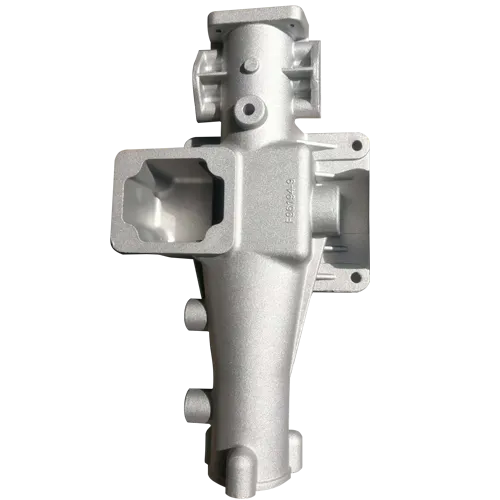

High-Quality Die Casting Services for Press Bars in Manchester Area

Press Bar Die Castings in Manchester A Comprehensive Overview

Die casting is a manufacturing process that has gained significant importance in various industries, particularly in the production of intricate and complex metal components. Among the diverse applications of die casting, press bar die castings have emerged as a popular choice in Manchester, a city known for its robust industrial landscape. In this article, we will explore the process of press bar die casting, its applications, advantages, and why Manchester is becoming a hub for this manufacturing technique.

Understanding Press Bar Die Castings

Press bar die casting involves the creation of precise and intricate shapes by forcing molten metal into a mold under high pressure. This technique ensures that the metal fills every detail of the mold, resulting in finely crafted components with excellent surface finishes. The process typically uses aluminum, zinc, or magnesium alloys; however, aluminum is widely favored due to its lightweight properties and corrosion resistance.

In press bar die casting, a 'bar' refers to a pre-shaped piece of metal that is used in various applications, including automotive components, consumer electronics, and industrial machinery. The strength and durability of the finished product make it ideal for high-performance applications.

The Process of Die Casting

The die casting process consists of several stages

1. Mold Design The first step in die casting is designing the mold, which is usually made of hardened steel. The mold must be precisely engineered to accommodate the desired shape and size of the final product.

2. Preparation The mold is then prepared by applying a release agent to facilitate easy removal of the finished cast.

3. Melting the Metal The chosen metal alloy is melted in a furnace until it reaches a liquid state.

4. Injection The molten metal is injected into the mold under high pressure, ensuring that it fills every cavity.

5. Cooling Once the mold is filled, the metal is allowed to cool and solidify, taking the shape of the mold.

6. Ejection After cooling, the mold opens, and the finished product is ejected.

7. Finishing The final step may involve finishing processes, including trimming, polishing, or machining to achieve the desired specifications.

pressbar die castings manchester

Applications of Press Bar Die Castings

Press bar die castings are utilized across a range of industries in Manchester, showcasing their versatility. Some common applications include

- Automotive Components Manufacturers use die castings for engine blocks, transmission cases, and other structural components where strength and lightweight properties are crucial. - Consumer Electronics With the increasing demand for lightweight and durable components, electronics manufacturers often rely on die castings for housings and internal structures.

- Industrial Machinery Heavy machinery components often require robust construction, making die castings an excellent choice for gears, brackets, and frames.

Advantages of Press Bar Die Castings

The adoption of press bar die castings offers several advantages

- Precision and Accuracy The high-pressure injection process allows for tight tolerances and detailed designs, leading to high-quality products.

- Cost-effectiveness While the initial setup might require investment, the high production rates make it a cost-effective solution for large-scale production.

- Material Efficiency Die casting minimizes waste, as the process yields a high percentage of useable material.

- Strength and Durability Components produced via die casting are known for their high strength-to-weight ratio, making them suitable for demanding applications.

Manchester A Hub for Die Castings

Manchester's rich industrial heritage and skilled workforce make it an ideal location for die casting operations. The city has seen advancements in technology and machinery, allowing manufacturers to improve efficiency and production capabilities. Additionally, the proximity to suppliers and a robust transportation network facilitate the timely delivery of materials and products.

In conclusion, press bar die castings are a vital component of modern manufacturing, offering precision, durability, and cost-effectiveness. As Manchester continues to embrace innovative manufacturing techniques, the future of die casting in the region looks promising, positioning itself as a leader in the industry. With the potential for further advancements and applications, the city stands ready to meet the growing demands of a competitive market.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025