Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Paddle Type Impeller - Innovative Mixing Technology for Enhanced Performance

Understanding Paddle Type Impellers

Paddle type impellers are crucial components in various industrial and laboratory applications, particularly in mixing and agitation processes. Their design is specifically tailored to enhance fluid movement and improve the efficiency of mixing operations. This article explores the characteristics, working principles, and applications of paddle type impellers.

Characteristics of Paddle Type Impellers

Paddle type impellers typically feature a set of flat blades that extend outwards, resembling the paddles of a boat. These blades are designed to create a flow of liquid by pushing it away from the center of the impeller as it rotates. Their shape and orientation can significantly affect the flow pattern and mixing efficiency, making design a vital aspect when selecting an impeller type for specific tasks.

The size, number, and angle of the paddles can be varied depending on the requirements of the application. For instance, wider paddles can move larger volumes of fluid but may require more energy to operate. In contrast, narrower paddles may require less power but might not provide the same level of agitation.

Working Principle

The working principle of paddle type impellers is based on the generation of mechanical energy through rotation. When the impeller spins, the paddles interact with the fluid, generating a shear force that facilitates mixing. This action creates a vortex that draws fluid into the impeller's center and then disperses it outward.

paddle type impeller

The effectiveness of paddle type impellers in mixing depends on several factors, including rotational speed, the viscosity of the fluid, and the configuration of the impeller. By optimizing these variables, operators can achieve enhanced mixing efficiency, reducing the time required for processes like homogenization, dilution, or chemical reactions.

Applications

Paddle type impellers are widely used in various industries, including food and beverage, pharmaceuticals, wastewater treatment, and chemical manufacturing. In food processing, they help achieve uniform consistency in products like sauces and dressings. In pharmaceuticals, paddle impellers are crucial for mixing ingredients in the production of medicines, ensuring that active components are evenly distributed.

In wastewater treatment, paddle type impellers are utilized in aeration tanks, promoting the mixing of wastewater with air to encourage the growth of aerobic bacteria, which are essential for breaking down organic matter. In chemical manufacturing, they enhance the dissolution of solids in liquids, facilitating reactions that require homogeneous mixtures.

Conclusion

Paddle type impellers are vital in many processes that require effective fluid mixing and agitation. Their ability to create uniform flow patterns makes them invaluable across various applications. Understanding their characteristics and working principles allows industries to optimize their processes, resulting in increased efficiency and productivity. As technology continues to evolve, the design and application of paddle type impellers will likely see further advancements, enhancing their effectiveness in diverse operations.

-

Understanding Metal Casting TechniquesNewsApr.02,2025

-

Understanding Exhaust Manifolds for Enhanced Engine PerformanceNewsApr.02,2025

-

The World of Metal FabricationNewsApr.02,2025

-

Key Components for Pump and Turbo EfficiencyNewsApr.02,2025

-

Essential Tools for Automotive Maintenance and RepairNewsApr.02,2025

-

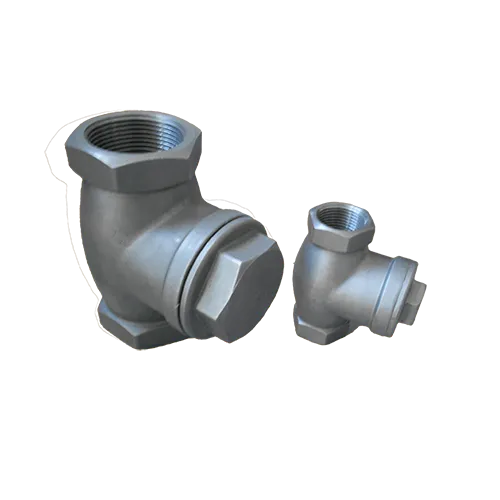

Durable Valve Components for Effective Water ManagementNewsApr.02,2025