Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Optimizing Performance with Oil-Infused Impeller Technology for Enhanced Efficiency

Understanding the Oil Impeller A Key Component in Fluid Dynamics

The oil impeller plays a critical role in the industry, particularly in fluid dynamics and pumping systems. This device is designed to impart kinetic energy to oil, making it essential for various applications, from automotive engines to large-scale industrial systems. Understanding the functionality, applications, and advantages of oil impellers is vital for engineers and technicians working in fields related to fluid transport and machinery.

What is an Oil Impeller?

An oil impeller is a rotating component that creates fluid motion within a system. It usually consists of blades or vanes that turn within a casing or housing. As the impeller spins, it uses centrifugal force to propel oil through a system, enabling efficient circulation, mixing, or even transfer from one area to another. The design and size of an impeller can significantly affect its performance and efficiency, making material selection and engineering critical factors in its implementation.

Working Principle

The fundamental working principle of an oil impeller is based on fluid mechanics. When the impeller rotates, it displaces the oil, creating a pressure differential that facilitates flow. As oil enters the impeller, the blades force it outward due to centrifugal action. This motion increases the oil's velocity, allowing it to travel through pipes and passageways to its designated location, be it an engine, hydraulic system, or lubrication circuit.

In many systems, multiple impellers are aligned to enhance performance, creating a series of pumping stages that amplify the pressure and flow rate of the oil. This technique is particularly useful in heavy-duty applications where high viscosity and large volumes of oil are involved.

Applications of Oil Impellers

Oil impellers are found in numerous applications across various industries. Some notable examples include

1. Automotive Engines In internal combustion engines, oil impellers facilitate the circulation of engine oil, ensuring that all components are adequately lubricated. This lubrication reduces friction, enhances performance, and prolongs engine life.

2. Hydraulic Systems Hydraulic systems rely on oil impellers to manage pressure and flow. Pumps equipped with impellers efficiently distribute hydraulic fluid, which powers machinery and equipment in construction, mining, and manufacturing.

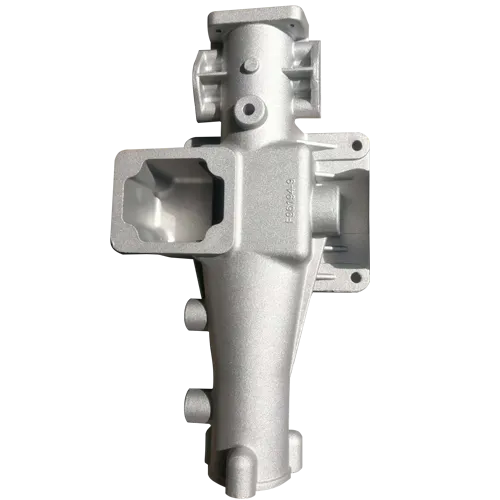

oil impeller

3. Petrochemical Industry In the petrochemical sector, oil impellers are crucial for transporting crude oil and its derivatives through pipelines. Their ability to handle large volumes and maintain stability makes them indispensable.

4. Cooling Systems In various cooling applications, oil impellers help circulate coolant fluid, assisting in temperature regulation of machinery and preventing overheating.

Advantages of Using Oil Impellers

The integration of oil impellers into fluid systems offers numerous advantages

- Efficiency Oil impellers are designed to maximize flow rates while minimizing energy consumption. Their optimized design allows them to operate efficiently across a range of conditions.

- Versatility Oil impellers can be tailored to meet specific requirements, making them suitable for various applications, from small motors to large industrial systems.

- Durability Constructed from high-quality materials, oil impellers can endure harsh operating conditions, including extreme temperatures and pressures.

- Ease of Maintenance Many impeller designs allow for easy access during maintenance, facilitating inspections and repairs without extensive downtime.

Conclusion

Oil impellers represent a fundamental component of fluid transport systems, showcasing the principles of fluid dynamics in practical applications. Their ability to efficiently circulate oil across various industries underlines their significance. As technology advances, the design and materials used in oil impellers will continue to evolve, further enhancing their capabilities and applications. Understanding these devices is essential for anyone involved in engineering, manufacturing, or maintaining systems reliant on fluid dynamics. The oil impeller is an unsung hero in the intricate dance of machinery and engineering, ensuring everything runs smoothly.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025