Mobile:+86-311-808-126-83

Email:info@ydcastings.com

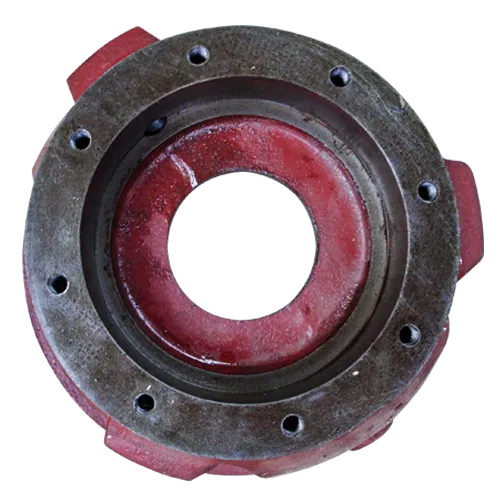

metal casting with 3d printed molds

The Future of Metal Casting Innovations with 3D Printed Molds

In recent years, the manufacturing industry has undergone a transformative shift driven by technological advancements. Among the most exciting developments is the integration of 3D printing technology with traditional metal casting methods. This innovation is set to redefine the parameters of efficiency, precision, and design freedom in metal casting processes.

Metal casting has been a fundamental process in manufacturing for centuries, allowing for the creation of complex shapes that would be challenging to achieve through other means. Traditionally, casting involves pouring molten metal into a mold designed to shape the final product. However, creating these molds can be a time-consuming and costly process, often requiring labor-intensive techniques and significant resources.

The Future of Metal Casting Innovations with 3D Printed Molds

Moreover, 3D printing enables the creation of highly complex and intricate mold designs that would be virtually impossible to achieve through conventional techniques. Designers can incorporate internal cooling channels, complex geometries, and lightweight structures directly into the mold, leading to enhanced performance and improved thermal management during the casting process. This capability not only optimizes the casting itself but also significantly reduces material waste, contributing to a more sustainable manufacturing approach.

metal casting with 3d printed molds

The flexibility of 3D printing also allows for greater customization of molds. Manufacturers can easily adapt their designs to accommodate specific client needs or respond to market demands without the costly retooling typically associated with traditional mold production. This agility is especially beneficial in industries where short production runs and bespoke components are the norm, such as aerospace or automotive sectors.

Furthermore, the integration of 3D printed molds into metal casting can lead to improved accuracy and consistency in the final products. Traditional molds can suffer from wear and degradation over time, affecting the quality of the casts produced. However, 3D printed molds can be designed for durability and can be rapidly replaced or refreshed without significant downtime in production. As a result, manufacturers can maintain high standards in quality control and reduce the likelihood of defects, leading to enhanced customer satisfaction.

While the benefits of using 3D printed molds in metal casting are clear, challenges remain. The materials used in 3D printing must be carefully selected to withstand the high temperatures and pressures of molten metal. Research and development in this area are ongoing, with innovations in materials science leading to better solutions for durable, heat-resistant molds. Additionally, the cost of 3D printing technology and materials can be a barrier for some companies, particularly smaller manufacturers. However, as the technology continues to advance and become more accessible, these obstacles are gradually diminishing.

In conclusion, the combination of metal casting and 3D printed molds represents a significant leap forward in manufacturing technology. This innovative approach not only accelerates production times and reduces costs but also unlocks new possibilities in design and customization that were previously unimaginable. As industries continue to evolve and embrace these advancements, the future of metal casting looks promising, paving the way for more efficient, sustainable, and creative manufacturing solutions. With ongoing research and commitment to overcoming existing challenges, we are likely to see widespread adoption of this technology, revolutionizing the way we think about metal casting for years to come.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025