Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Exploring the Properties and Applications of Martensitic Stainless Steel Castings in Industry

Martensitic Stainless Steel Castings A Comprehensive Overview

Martensitic stainless steel castings are an essential component in various industries, known for their unique combination of strength, corrosion resistance, and hardness. Derived from the martensitic microstructure, these materials are primarily created using the iron-carbon alloy system, which undergoes a specific heat treatment process to achieve the desired mechanical properties.

Understanding Martensitic Stainless Steel

Martensitic stainless steel is characterized by its high carbon content (typically between 0.1% and 1.2%) and specific alloying elements such as chromium (12-18%) and nickel (less than 2%). This composition plays a pivotal role in enhancing the material's hardness and strength while providing essential corrosion resistance. The martensitic structure is formed during the cooling process of the molten steel, whereby the austenite phase transforms into martensite through rapid cooling or quenching. This transformation results in a harder and more durable material compared to its austenitic counterparts.

Advantages of Martensitic Stainless Steel Castings

One of the primary advantages of martensitic stainless steel castings is their exceptional strength. The heat treatment process allows for increased hardness, making these castings suitable for applications that require high load-bearing capabilities. Additionally, the corrosion resistance provided by the chromium content is critical for components exposed to harsh environments, such as chemical processing or marine applications.

Moreover, martensitic stainless steel castings can easily be machined to precise dimensions. Unlike some other stainless steel grades, they offer better machinability, allowing manufacturers to create intricate designs and complex geometries. This versatility makes martensitic stainless steel an attractive choice for industries such as aerospace, automotive, medical devices, and oil and gas.

Applications

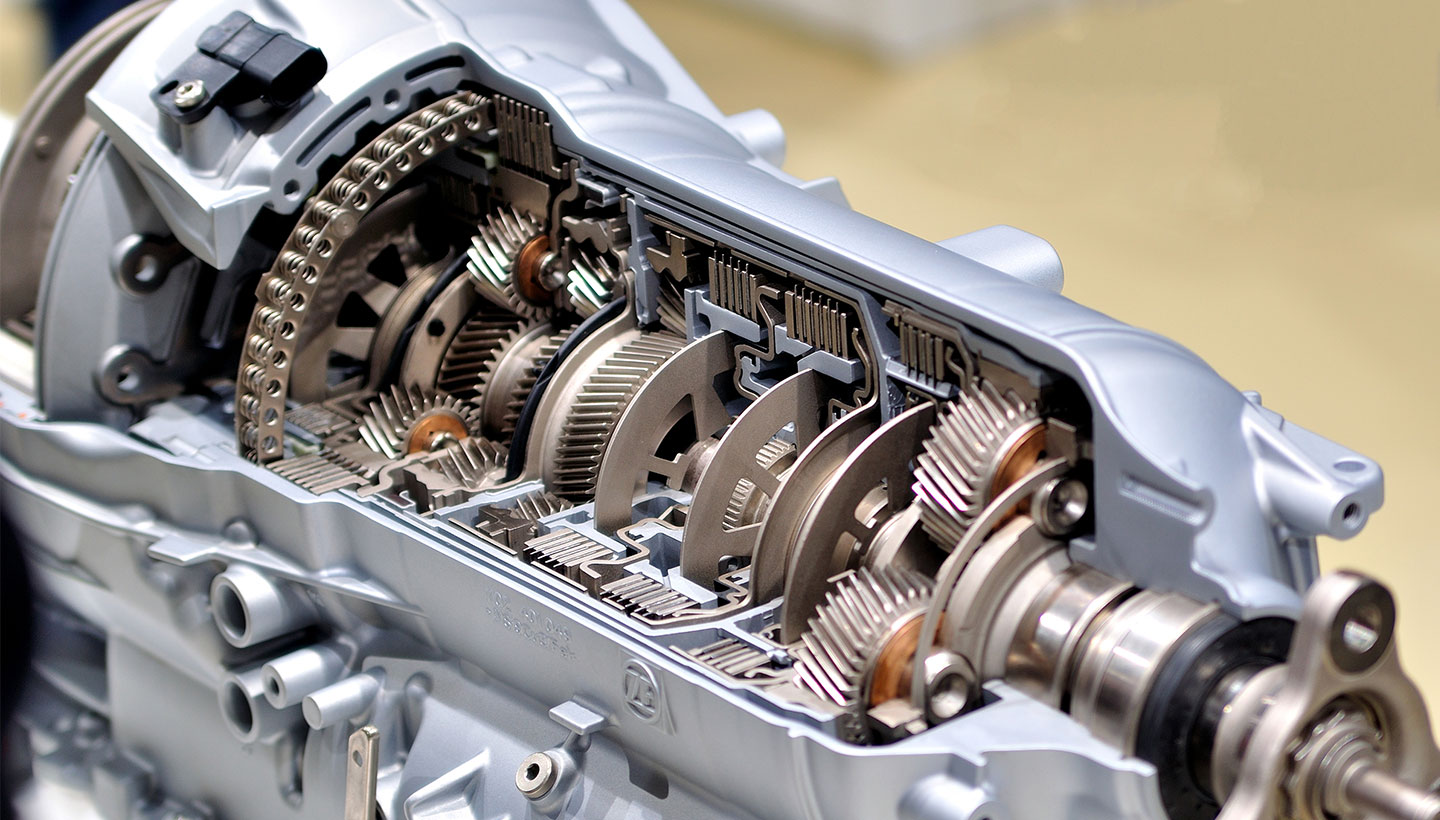

martensitic stainless steel castings

The remarkable properties of martensitic stainless steel castings make them ideal for a wide range of applications. In the aerospace industry, components such as landing gear, fasteners, and turbine parts are manufactured using these materials due to their ability to withstand high stress and fatigue. In the automotive sector, they are commonly used in engine components and exhaust systems, which require both strength and resistance to corrosion.

Furthermore, in the medical field, martensitic stainless steel is utilized in surgical instruments and implants, where biocompatibility and sterilization processes are critical. The oil and gas industry also relies on martensitic stainless steel castings for valves, pumps, and other equipment that operate in corrosive environments under high-pressure conditions.

Challenges and Considerations

Despite their advantages, martensitic stainless steel castings are not without challenges. The manufacturing process requires precision and careful control of temperature and cooling rates to ensure the desired microstructure is achieved. Improper heat treatment can lead to undesirable properties such as brittleness or reduced toughness.

Moreover, while martensitic stainless steel offers good corrosion resistance, it is not as resistant as austenitic stainless steels in extremely corrosive environments. Therefore, the selection of material must consider the specific application and environmental conditions to ensure optimal performance.

Conclusion

Martensitic stainless steel castings represent a remarkable fusion of strength, hardness, and corrosion resistance, making them vital in various industries. Their unique properties allow for diverse applications, from aviation to medical devices. However, careful attention must be paid to the manufacturing process and application environment to maximize their performance. As industries continue to evolve and demand higher-performing materials, martensitic stainless steel castings will undoubtedly remain a key player in the materials engineering landscape.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025