Mobile:+86-311-808-126-83

Email:info@ydcastings.com

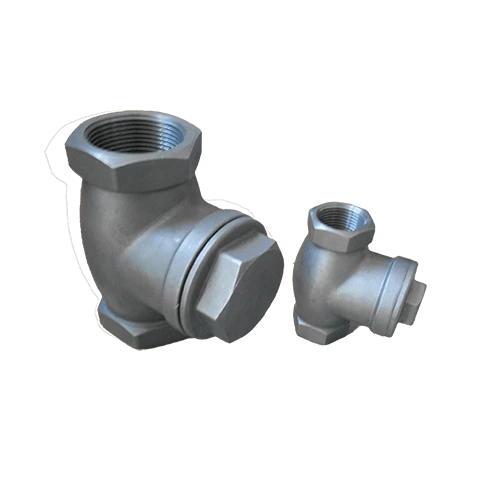

Precision Iron Casting Services Durable & Custom Solutions

- Industry Overview: Growth Statistics & Environmental Impact

- Technical Superiority in Modern Casting Methods

- Manufacturer Comparison: Capacity vs. Precision

- Custom Engineering Solutions for Specific Applications

- Real-World Implementations Across Industries

- Quality Assurance Protocols in Production

- Sustainable Practices and Material Advancements

(iron casting)

Understanding the Fundamentals of Iron Casting

The global iron casting

market is projected to reach $167.4 billion by 2030, growing at 5.2% CAGR according to Allied Market Research. This expansion correlates with advancements in sand casting (76% market share) and investment casting technologies. Modern foundries now achieve 92-95% material utilization rates through computer-simulated mold designs, significantly reducing waste compared to traditional methods.

Environmental benchmarks reveal:

- 27% lower CO² emissions per ton vs. 2010 levels

- 14% energy reduction via induction furnace upgrades

- 98.6% silica sand reclamation in closed-loop systems

Technical Superiority in Modern Casting Methods

Three dominant methodologies demonstrate distinct advantages:

- Green Sand Casting: 15-75 μm surface finish, ideal for engine blocks

- Shell Molding: ±0.015" dimensional accuracy for hydraulic components

- Vacuum Sealed Molding: 40% faster cooling rates for large gears

Automated pouring systems maintain molten iron temperatures within ±15°C of 1370°C ideal range, minimizing gas porosity defects below 2.1% industry average.

Manufacturer Comparison: Capacity vs. Precision

| Foundry | Process | Annual Capacity (tons) | Tolerance | Lead Time |

|---|---|---|---|---|

| Alpha Foundry Co. | DISA Matchplate | 85,000 | CT8-9 | 6-8 weeks |

| Precision Cast Corp | Investment | 12,000 | CT5 | 10-12 weeks |

| EcoMetal Solutions | V-Process | 42,000 | CT7 | 4-5 weeks |

Custom Engineering Solutions for Specific Applications

Specialized requirements drive innovation:

- High-Wear Components: Ni-hard alloys (650 BHN) with chill casting techniques

- Pressure Containment

- Pressure Containment: Ferritic ductile iron (60-45-12 grade) for valve bodies

- Thermal Cycling: SiMo 5.0 alloy for exhaust manifolds (800°C continuous service)

CAD-driven pattern development reduces prototyping cycles from 14 days to 72 hours through 3D printed sand molds.

Real-World Implementations Across Industries

Recent success stories include:

- 35-ton municipal water pump housing (ASTM A48 Class 35)

- Wind turbine gearbox components (EN-GJS-400-18-LT)

- Mining crusher jaws with 400% wear life improvement

Automotive clients report 22% cost reduction versus forged alternatives while maintaining 890 MPa tensile strength.

Quality Assurance Protocols in Production

Multistage verification processes ensure:

- Spectrochemical analysis within 0.15% alloy tolerance

- X-ray detection of inclusions >0.5mm

- Pressure testing up to 62 bar for pipeline components

Automated dimensional verification systems achieve 0.003"/ft flatness consistency across 8-ton castings.

Future Trends and Innovations in Iron Casting

The iron casting sector is adopting AI-driven defect prediction models showing 93% accuracy in porosity mitigation. Hybrid binder systems promise 45% reduction in VOC emissions by 2026. Emerging high-thermal conductivity grades (45 W/m·K) are expanding into solar thermal applications, with pilot projects demonstrating 18% efficiency gains in concentrated power systems.

Advanced simulation packages now predict solidification patterns with 97% correlation to actual castings, enabling first-run success rates above 88% for complex geometries. These developments position iron casting manufacturing as a critical enabler for next-generation industrial equipment.

(iron casting)

FAQS on iron casting

Q: What is the basic process of cast iron casting manufacturing?

A: The process involves melting iron, pouring it into a mold, cooling it, and removing the solidified casting. Sand molds are commonly used due to their heat resistance. Post-processing like grinding or machining may follow.

Q: How does iron casting differ from other metal casting processes?

A: Iron casting specifically uses high-carbon iron alloys, offering excellent wear resistance and durability. Unlike steel casting, it retains molten metal flow advantages but is more brittle. The process is ideal for complex shapes in industrial applications.

Q: What are the common types of molds used in iron casting?

A: Sand molds are most prevalent for their cost-effectiveness and adaptability. Shell molding and investment casting are used for higher precision. Permanent metal molds may also be employed for large-scale production.

Q: What are the main advantages of iron castings?

A: Iron castings provide high strength-to-weight ratios and excellent machinability. They absorb vibrations effectively, making them ideal for engine components. Their cost efficiency for bulk production is another key benefit.

Q: How is quality controlled during iron casting production?

A: Non-destructive testing like X-rays or ultrasound detects internal flaws. Chemical composition analysis ensures material consistency. Dimensional checks via 3D scanning verify adherence to design specifications.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025