Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Investment Casting Techniques for High-Performance Ball Valves Production and Design

Investment Casting Ball Valve A Comprehensive Overview

Investment casting, also known as lost-wax casting, is a sophisticated manufacturing process renowned for its ability to produce complex shapes with high precision. Among the various applications of investment casting, one of the most significant is in the production of ball valves. Ball valves are essential components in numerous industries, including oil and gas, water treatment, and HVAC systems, due to their reliable performance and durability.

What is a Ball Valve?

A ball valve is a type of valve that uses a spherical obstruction (the ball) to control the flow of fluid through a pipe. The ball has a hole through its center that allows fluid to flow when aligned with the pipe’s flow direction. When the ball is rotated perpendicular to the flow, the valve is closed. This simple yet effective mechanism makes ball valves ideal for on-off applications. They are favored over other valve types because of their low flow resistance and ability to create a tight seal.

The Role of Investment Casting in Manufacturing Ball Valves

The investment casting process is particularly beneficial for producing ball valves due to its ability to create intricate designs and achieve tight tolerances. The process begins with creating a wax pattern of the valve components, including the body, ball, and other critical features. Once the wax pattern is created, it is coated with a ceramic shell, which is then heated to melt away the wax, leaving a hollow cavity in the shape of the valve.

Next, molten metal—often made of high-quality alloys resistant to corrosion and high temperatures—is poured into the ceramic mold. This method allows for the production of parts with intricate shapes that would be difficult or impossible to create with traditional machining techniques. After the metal has cooled and solidified, the ceramic shell is removed, and the finished ball valve is cleaned and inspected for quality.

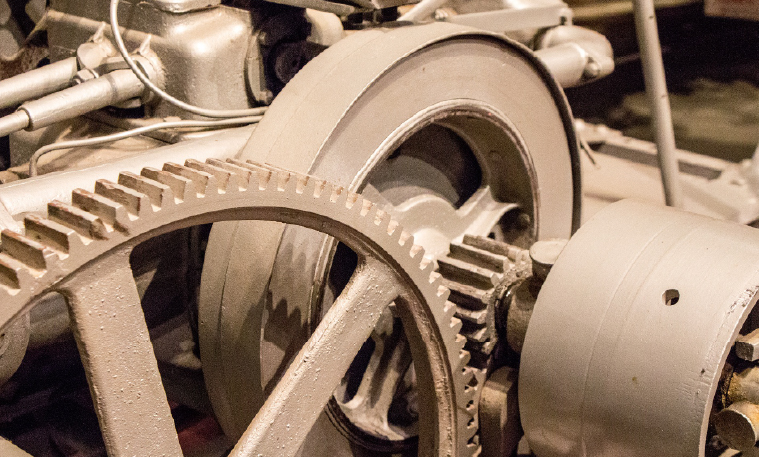

investment casting ball valve

Advantages of Investment Casting for Ball Valves

One of the primary advantages of using investment casting for ball valves is the ability to produce components with excellent surface finishes and fine details. This is vital in ensuring that the ball valve operates effectively and maintains integrity under various pressure and temperature conditions. Additionally, investment casting reduces material waste compared to other manufacturing methods, which enhances economic efficiency.

Moreover, investment casting allows for the use of a wide range of materials, providing designers with the flexibility to choose the best alloy for specific applications. This feature is especially important in environments that may expose the valve to corrosive substances or extreme temperatures.

Applications of Investment Casting Ball Valves

Investment casting ball valves are extensively used in various sectors. In the oil and gas industry, they are crucial for controlling the flow of crude oil and natural gas. In water treatment facilities, they help manage water distribution and treatment processes. Their applications extend to chemical processing, power generation, and food and beverage production, where reliability and precision are critical.

Conclusion

Investment casting ball valves represent a blend of innovation and practicality in valve manufacturing. Their superior quality, durability, and versatility make them a preferred choice in various industrial applications. As industries continue to evolve and require efficient fluid control solutions, the importance of investment casting in producing high-quality ball valves will undoubtedly grow. This casting method not only enhances performance but also contributes to sustainable manufacturing practices, thereby paving the way for future advancements in valve technology.

-

Why Is Choosing the Right Motor Housing Critical for Engine Performance?NewsJul.18,2025

-

Which Impeller Types Best Optimize Your Pump’s Efficiency?NewsJul.18,2025

-

Optimize Maintenance Efficiency with Durable Oil Catch SolutionsNewsJul.18,2025

-

Maximize Pump Performance with Precision-Engineered ComponentsNewsJul.18,2025

-

Elevate Industrial Flow Systems with Precision-Engineered ComponentsNewsJul.18,2025

-

Boost Durability and Functionality with Precision Power CastingsNewsJul.18,2025