Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Investment Cast 316 Stainless Steel - Precision Engineering Solutions

Investment casting is a highly refined manufacturing process that enables the creation of intricate and high-precision metal parts. One of the most popular materials used in this process is 316 stainless steel, known for its excellent corrosion resistance, strength, and durability.

316 stainless steel is an austenitic stainless steel alloy primarily composed of iron, chromium, nickel, and molybdenum. Its unique composition provides enhanced resistance to pitting and crevice corrosion in chloride environments, making it an ideal choice for applications in marine, chemical, and pharmaceutical industries. The addition of molybdenum not only enhances its overall corrosion resistance but also improves its strength at elevated temperatures, further expanding its application range.

Investment casting is a highly refined manufacturing process that enables the creation of intricate and high-precision metal parts

. One of the most popular materials used in this process is 316 stainless steel, known for its excellent corrosion resistance, strength, and durability.Investment casting 316 stainless steel components presents several benefits. First and foremost, the precision of the investment casting process means that components can be manufactured with tight tolerances and superior surface finishes. This level of accuracy is crucial in industries where component reliability and performance are paramount. Furthermore, the process is highly repeatable, allowing for consistent production of identical parts—a critical factor for manufacturers producing large quantities.

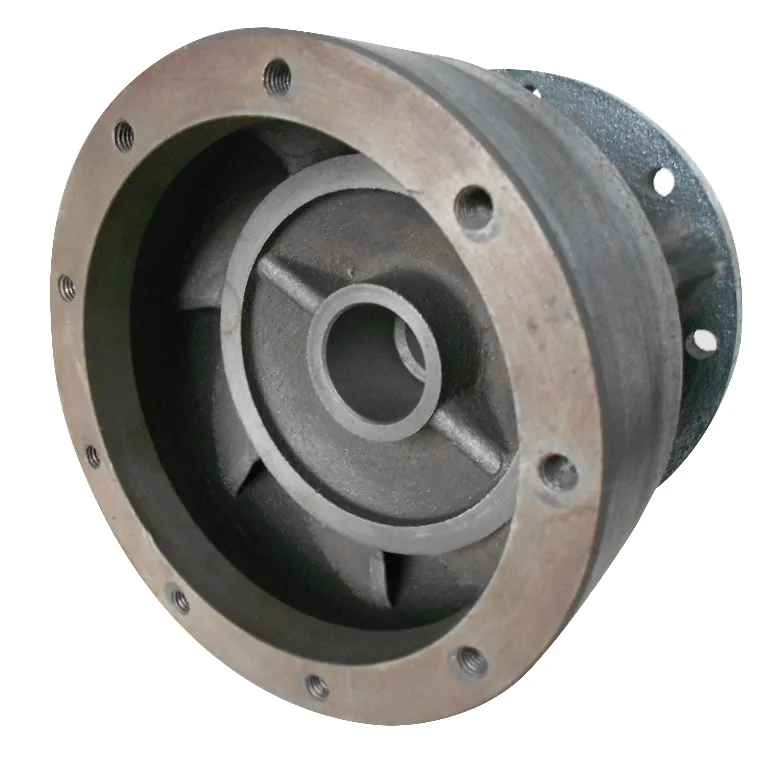

investment cast 316 stainless steel

Another advantage of investment casting is its ability to produce thin-walled components, which is often challenging with other manufacturing methods. The lightweight nature of thin-walled parts combined with the strength of 316 stainless steel makes them optimal for applications where reducing weight is essential, such as in aerospace and automotive industries.

Moreover, 316 stainless steel’s resilience to corrosion extends the life of the components, reducing maintenance costs and downtime. Parts manufactured through investment casting can be used in harsh environments without compromising integrity or performance, making this material choice particularly valuable in sectors such as oil and gas, food processing, and wastewater treatment.

In conclusion, investment casting 316 stainless steel combines the precision of modern manufacturing techniques with the innate advantages of high-performance materials. This synergy allows for the production of sophisticated parts that meet the demanding standards of various industries, making investment casting a pivotal process in contemporary manufacturing landscapes. As industries continue to evolve, the role of investment casting in delivering innovative solutions will undoubtedly expand, further cementing its significance in the field.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025