Mobile:+86-311-808-126-83

Email:info@ydcastings.com

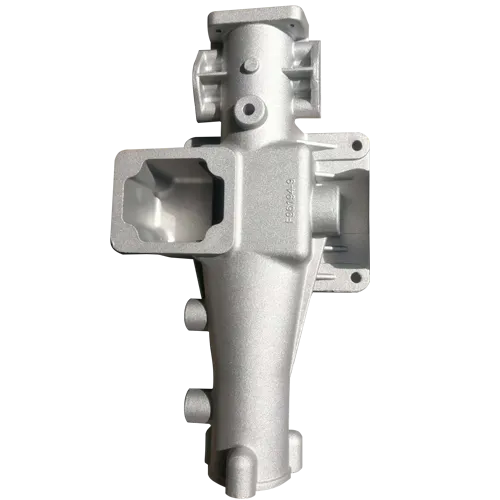

impeller on pump

The Importance of Impellers in Pump Performance

Pumps are essential devices in a wide range of industrial, agricultural, and municipal applications. They are designed to move fluids from one location to another, a task that relies heavily on a crucial component known as the impeller. The impeller is a rotating machine element that transfers energy from the motor to the fluid, playing a key role in the pump's efficiency and effectiveness.

The Importance of Impellers in Pump Performance

The performance of a pump is largely determined by the design of its impeller. Impellers can be classified into various types, including closed, semi-open, and open impellers. Closed impellers, which have blades sandwiched between two discs, are known for their ability to handle higher pressures and are typically used in applications requiring a higher degree of sealing. Semi-open impellers have blades that are attached to a hub but are open on one side, making them suitable for handling fluids with solids or debris. Open impellers, with their exposed blades, are often used in applications where the fluid contains large particulates.

impeller on pump

The choice of impeller type is crucial when selecting a pump for a specific application. For instance, in wastewater treatment facilities, open impellers are preferred due to their capability to handle solids without clogging. In contrast, closed impellers are selected for clean water applications where efficiency and higher discharge pressures are critical.

Another key factor in impeller performance is its material composition. Impellers can be made from a variety of materials including stainless steel, plastic, and bronze, depending on the type of fluid being pumped and the operating environment. Corrosion resistance and wear resistance are important considerations in the material selection process, especially in aggressive or abrasive fluid conditions.

In addition to design and materials, the speed at which the impeller rotates also plays a vital role in pump efficiency. Higher rotational speeds can increase the flow rate and pressure of the fluid, but this must be balanced against potential wear and energy consumption. Properly sizing the impeller and optimizing its rotation speed are essential for achieving the desired performance levels while maintaining longevity and reliability.

In conclusion, the impeller is a fundamental component of any pump, directly influencing its performance and efficiency. Understanding the different types of impellers, their design implications, and material choices can help in making informed decisions when selecting a pump for various applications. As industries continue to evolve, advancements in impeller design and technology will undoubtedly enhance fluid transfer processes, supporting productivity and operational efficiency in countless settings.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025