Mobile:+86-311-808-126-83

Email:info@ydcastings.com

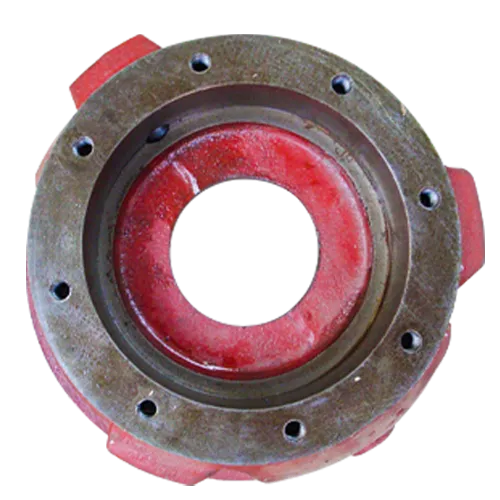

hose connector for submersible pump

Understanding Hose Connectors for Submersible Pumps

Submersible pumps are essential components in various applications, including groundwater extraction, sewage pumping, and drainage in construction sites. They operate underwater and are designed to efficiently move fluid from one location to another. One critical aspect of these pumps is the hose connector, a component that plays a vital role in ensuring optimal performance and easy installation. In this article, we will delve into the significance of hose connectors for submersible pumps, their types, and best practices for their selection and maintenance.

What is a Hose Connector?

A hose connector is a fitting that joins a hose to a submersible pump, allowing the pumped fluid to be directed to a desired location. This connector is crucial for maintaining a secure and leak-proof connection, ensuring that the pump operates efficiently without losing pressure. Hose connectors come in various shapes, sizes, and materials, each designed to cater to specific pumping requirements.

Types of Hose Connectors

There are several types of hose connectors used with submersible pumps, including

1. Barbed Connectors These are the most common type of hose connectors. They feature ridges that grip onto the hose securely. Barbed connectors are typically made of plastic or brass, providing a robust connection that is easy to install.

2. Threaded Connectors These connectors have male or female threads that screw into corresponding fittings. They are ideal for high-pressure applications, providing a very secure connection. Threaded connectors are usually made of metal or durable plastic.

3. Quick Connectors Quick connectors are designed for rapid connection and disconnection, making them ideal for temporary setups or frequent changes in configuration. They are user-friendly and available in various materials, including brass and nylon.

4. Clamp Connectors These connectors use a clamp to secure the hose around the fitting. This type is often used when dealing with larger hoses or high-flow applications where a tight seal is necessary.

Choosing the Right Hose Connector

Selecting the appropriate hose connector for your submersible pump is crucial for ensuring efficiency and longevity

. Here are some factors to considerhose connector for submersible pump

- Compatibility Ensure that the hose connector is compatible with both the hose and the pump. Check the diameter, pressure rating, and thread type to ensure a perfect fit.

- Material The material of the connector must be suitable for the type of liquid being pumped. For example, corrosive liquids require connectors made of resistant materials like stainless steel or specific plastics.

- Pressure Rating Depending on the application, the connector must withstand specific pressure ratings. Overloading a connector beyond its rated capacity can lead to leaks, equipment damage, or even failure.

- Temperature Range If the fluid being pumped may reach extreme temperatures, ensure the connector can handle those conditions without degrading.

Maintenance of Hose Connectors

Proper maintenance of hose connectors is necessary to prolong their life and ensure consistent pump operation. Here are some tips

- Regular Inspections Periodically check connectors for signs of wear, corrosion, or damage. Replace any parts that show degradation to prevent leaks.

- Secure Connections Ensure that all connections are tight and leak-free. Regularly check hose clamps and threaded connections, especially after significant use.

- Store Properly When not in use, store hoses and connectors in a cool, dry place to avoid exposure to harsh environmental conditions that could lead to wear.

- Use Sealants Wisely In some cases, thread sealants may be applied to threaded connections to prevent leaks. Ensure that the sealant is compatible with the materials being used.

Conclusion

Hose connectors are a fundamental component of submersible pumps, affecting their efficiency and reliability. By understanding the types of connectors available, how to select the right one, and the importance of maintenance, users can enhance their pumping operations. Whether you are working in agriculture, construction, or wastewater management, choosing the right hose connector can make a significant difference in performance and operational efficiency. Always invest time in choosing the appropriate equipment, as it will ultimately lead to greater reliability and success in your projects.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025