Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Exploring the Benefits and Applications of Gunmetal Impellers in Modern Machinery

The Significance of Gunmetal Impellers in Modern Engineering

In the realm of modern engineering, particularly within the fields of fluid dynamics and mechanical systems, the choice of materials plays a crucial role in determining the efficiency, durability, and performance of components. One such essential component is the impeller, which is integral to various machines, including pumps, turbines, and compressors. Among the different materials used for manufacturing impellers, gunmetal has emerged as a preferred choice for several applications, thanks to its unique properties and advantages.

Gunmetal, an alloy primarily composed of copper, tin, and zinc, is renowned for its excellent strength, corrosion resistance, and wear resistance. These characteristics make it an ideal candidate for creating impellers that operate in challenging environments, such as those found in marine applications or chemical processing industries. The corrosion resistance of gunmetal ensures that impellers maintain their structural integrity even when exposed to aggressive fluids, thereby extending their operational lifespan and reducing maintenance costs.

One of the primary reasons engineers favor gunmetal impellers is their superior mechanical properties. Gunmetal impellers can withstand significant stresses without deforming, which is critical in high-performance applications where failure can lead to severe consequences. Additionally, the density of gunmetal contributes to the stability of the impeller, allowing for smoother operation and enhanced performance in pumping applications. The material's ability to handle varying flow rates and pressures makes it versatile and suitable for a wide range of industrial uses.

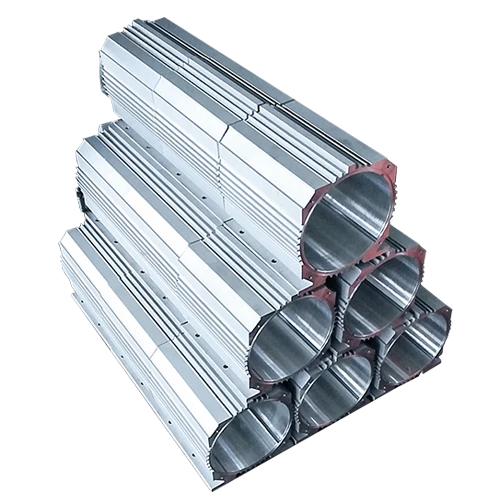

gunmetal impeller

Moreover, gunmetal impellers offer outstanding casting properties, allowing for intricate designs that can improve fluid dynamics. The precise manufacturing capabilities enable the production of impellers that not only meet specific performance requirements but also contribute to overall system efficiency. When designed correctly, gunmetal impellers can minimize energy losses and optimize fluid flow, which is particularly valuable in systems where energy efficiency is paramount.

In recent years, advancements in manufacturing technologies and material science have further enhanced the performance characteristics of gunmetal impellers. Techniques such as precision casting and advanced surface treatments have led to impellers that exhibit even greater durability and efficiency. Consequently, the application of gunmetal impellers continues to expand across various industries, from municipal water treatment facilities to aerospace propulsion systems.

In conclusion, the significance of gunmetal impellers in modern engineering cannot be overstated. Their unique combination of strength, corrosion resistance, and excellent casting properties makes them an invaluable asset in designing reliable and efficient machinery. As industries continue to evolve and demand more robust and efficient solutions, the role of gunmetal impellers will undoubtedly remain prominent in the engineering landscape, driving innovation and performance to new heights.

-

Impeller Technology That Powers Precision in Pump SystemsNewsMay.22,2025

-

Valve Durability Begins with Quality Cast Iron ComponentsNewsMay.22,2025

-

Performance Cooling with Advanced Automobile Water Pump SolutionsNewsMay.22,2025

-

How Motor Housing and Oil Pans Shape Engine PerformanceNewsMay.22,2025

-

How Metal Castings Drive Modern Manufacturing EfficiencyNewsMay.22,2025

-

Exploring the Engineering Behind Valve Body CastingsNewsMay.22,2025