Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Affordable Solutions for Gas Line End Caps for Safe and Effective Usage

Understanding Gas Line End Caps An Essential Safety Component

Gas line end caps play a crucial role in the safe and efficient operation of gas distribution systems. Whether in industrial, commercial, or residential applications, these components help to ensure that gas systems function safely and effectively. This article will explore what gas line end caps are, their importance, applications, and best practices for their use.

What Are Gas Line End Caps?

Gas line end caps are fittings that seal the end of a gas pipe. They are designed to prevent the escape of gas from the end of a gas line, thereby reducing the risk of leaks that can pose safety hazards. Made from various materials such as steel, brass, or plastic, these caps are tailored to withstand the pressure and corrosive nature of different gas types, including natural gas, propane, and other combustible fuels.

Importance of Gas Line End Caps

The primary function of gas line end caps is to provide a secure closure for gas pipes. This closure is vital for several reasons

1. Safety By preventing gas leaks, end caps minimize the risk of fire or explosion, protecting both property and lives. A small leak can lead to disastrous consequences, making proper sealing a critical safety measure. 2. Maintenance End caps also facilitate maintenance activities. When a gas line is not in use or requires repairs, caps can effectively seal the line, preventing any gas from escaping until the line is reactivated.

3. Regulatory Compliance Adhering to safety standards and regulations is paramount in the gas industry. Using end caps helps businesses comply with safety regulations set forth by organizations such as OSHA and NFPA, ensuring operational integrity.

Applications of Gas Line End Caps

Gas line end caps are used in a variety of settings, including

gas line end cap

- Residential Homes Homeowners may utilize end caps in various gas applications, from appliances to outdoor grills, to securely seal unused gas lines. - Industrial Facilities Factories and manufacturing plants frequently have complex gas systems that require robust end caps to manage high pressures and flow rates effectively.

- Commercial Establishments Restaurants and commercial kitchen settings use gas lines for cooking equipment, making the use of end caps essential during installation, maintenance, or when equipment is removed.

Best Practices for Using Gas Line End Caps

To ensure the effectiveness and longevity of gas line end caps, consider the following best practices

1. Choose the Right Material Select end caps that are compatible with the type of gas and pressure in the system. Using the wrong material can lead to failures and safety hazards.

2. Regular Inspections Conduct routine checks to ensure that end caps are in good condition. Look for signs of wear, leaks, or corrosion, especially in high-demand or older gas lines.

3. Proper Installation Ensure that end caps are installed correctly, using appropriate tools and techniques. Any misalignment or improper sealing can compromise safety.

4. Follow Regulations Be aware of and comply with local building codes and safety standards regarding gas line installations and maintenance.

Conclusion

Gas line end caps are small yet significant components in the maintenance of gas safety. By understanding their importance and proper application, individuals and businesses can protect themselves from potential dangers while ensuring their gas systems operate efficiently. Investing in quality materials and adhering to best practices can mitigate risks and promote safe usage in various environments.

-

Automobile Water Pumps in Vehicle PerformanceNewsMay.21,2025

-

Valve Box Cover Cast Iron: The Backbone of Fluid Control SystemsNewsMay.21,2025

-

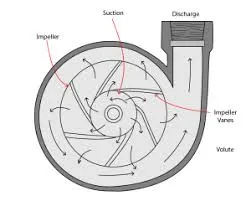

Pump Impeller in Fluid DynamicsNewsMay.21,2025

-

Baffled Oil Pans in Racing Cars: How They Improve PerformanceNewsMay.21,2025

-

Compressor Housing Turbo in Pump EngineeringNewsMay.21,2025

-

Why Oil Pan Thickness Matters for Engine SafetyNewsMay.21,2025