Mobile:+86-311-808-126-83

Email:info@ydcastings.com

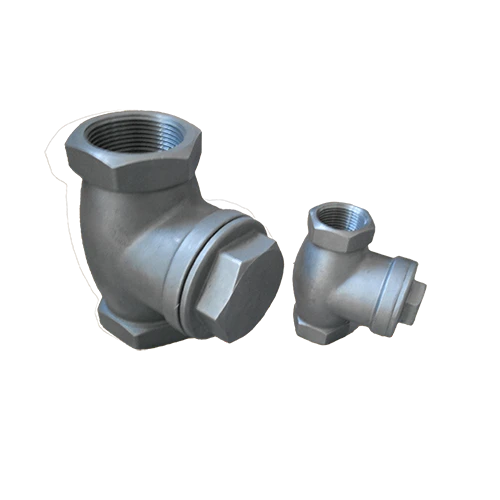

Galvanized End Cap for Durable Pipe Fittings and Connections in Plumbing Systems

The Importance and Applications of Galvanized End Caps

Galvanized end caps are essential components in various industries, particularly in the fields of plumbing, construction, and manufacturing. These fittings, which are designed to secure the open ends of pipes, play a significant role in ensuring the integrity and longevity of piping systems. The term galvanized refers to the process of coating steel or iron with a layer of zinc to prevent rust and corrosion, making these end caps particularly durable.

Overview of Galvanization

The galvanization process involves taking a base metal, typically iron or steel, and immersing it in molten zinc or applying a zinc coating through electroplating. This zinc layer acts as a sacrificial barrier, which means that it will corrode before the underlying metal, thus extending the life of the product significantly. Galvanized end caps leverage this protection to be used in a wide variety of environments, from indoor plumbing systems to outdoor construction.

Applications in Plumbing

In plumbing, galvanized end caps are commonly used in both residential and commercial pipelines. They are crucial for sealing the ends of pipes that may not be in use, helping to prevent leaks and contamination. This is particularly important when dealing with water supply lines, where maintaining clean and safe water is paramount. By using galvanized fittings, plumbers can ensure that their installations are not only functional but also resilient against the elements.

Construction Industry Use

In the construction sector, galvanized end caps are often employed in scaffolding and structural applications. These caps are used to close off the ends of pipes used in scaffolding to ensure safety and stability. The galvanized coating protects the pipes from the corrosion that can occur when they are exposed to various weather conditions. This durability helps maintain a safer working environment on construction sites, where structural integrity is critical.

galvanized end cap

Benefits of Using Galvanized End Caps

1. Corrosion Resistance The primary advantage of galvanized end caps is their resistance to rust and corrosion, which is particularly crucial in humid or outdoor environments. This feature greatly extends the life of the piping systems.

2. Cost-Effectiveness While the initial investment in galvanized materials may be slightly higher compared to non-galvanized alternatives, the long-term savings as a result of reduced maintenance and replacement costs make galvanized end caps a wise choice.

3. Versatility These fittings can be used in a variety of applications beyond plumbing and construction, including automotive, HVAC systems, and even furniture design. Their adaptability across multiple sectors highlights their importance in modern engineering and design.

4. Easy Installation Galvanized end caps feature standardized fittings that allow for straightforward installation and integration into existing piping systems, saving time and labor costs during the installation process.

Conclusion

In summary, galvanized end caps are an integral part of many piping systems across different industries. Their ability to resist corrosion, combined with the cost-effectiveness and versatility, make them a preferred choice for professionals in plumbing, construction, and many other fields. As industries continue to prioritize sustainability and longevity in their material choices, galvanized end caps will undoubtedly maintain their status as vital components in ensuring the durability and reliability of piping systems. Whether for sealing unused pipe ends, reinforcing structures, or facilitating safe water systems, the role of galvanized end caps cannot be overstated.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025