Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Exploring the Features and Benefits of 12% Pipe Caps for Efficient Sealing Solutions

Understanding the 12% Pipe Cap Functionality and Applications

In the realm of piping systems, understanding components such as the 12% pipe cap is essential for engineers, contractors, and system designers. The 12% pipe cap is a specific type of pipe fitting used widely in various industries, including oil and gas, water supply, and chemical processing. Its design plays a crucial role in ensuring the integrity and efficiency of piping systems.

What is a 12% Pipe Cap?

Essentially, a pipe cap is a fitting used to seal the end of a pipe. The designation 12% typically indicates the angle of taper or the specific design characteristics of the cap. A 12% pipe cap is designed to accommodate a reduction in the outer diameter of the pipe toward the terminal end. This tapering allows for a better fit and less stress concentration at the junction, which is particularly important in high-pressure applications.

Importance of Pipe Caps

Pipe caps serve several functions in piping systems. Foremost among them is their ability to seal off the ends of pipes, which prevents the passage of fluids or gases, ensuring that the system remains efficient and leak-free. In addition to sealing, they can also serve as inspection points, allowing for easy access to the inner workings of the system. This feature is particularly useful for maintenance and inspection purposes.

Another critical function of the 12% pipe cap is its contribution to system safety. In many high-pressure applications, the integrity of the piping system is paramount. A properly installed and fitted cap can prevent catastrophic failures, such as blowouts or leaks, safeguarding both personnel and environment.

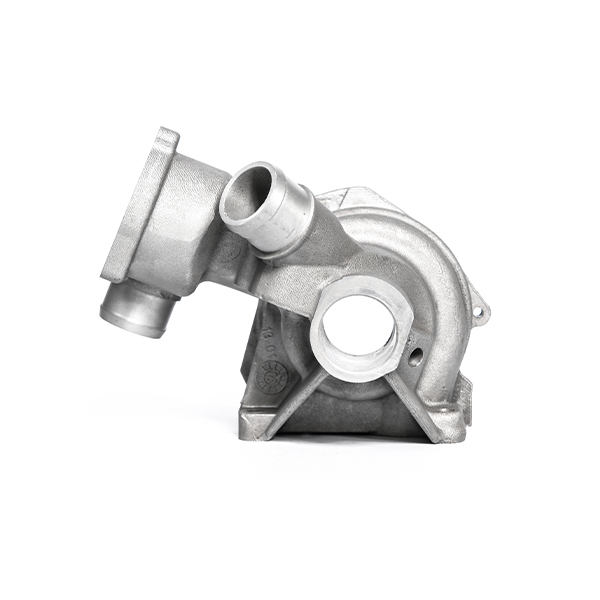

12 pipe cap

Applications of 12% Pipe Caps

The versatility of the 12% pipe cap allows it to be used across various sectors. In the oil and gas industry, for example, these caps are employed to close off wellheads or pipelines, serving as a safeguard against spills and leaks. In water treatment plants, they are utilized to cap off pipelines during maintenance or when new sections are being added.

In manufacturing facilities, 12% pipe caps can be used in conjunction with stainless steel or carbon steel pipes, depending on the required resistance to corrosion and temperature. In chemical processing plants, the ability of pipe caps to withstand harsh chemicals makes them an indispensable component.

Installation Considerations

When installing a 12% pipe cap, it is essential to ensure that the cap is compatible with the pipe material and size. Incorrect fittings can lead to leaks and system failures. Additionally, proper torque specifications should be adhered to during installation to achieve a secure fit without over-tightening, which can compromise the integrity of both the cap and the pipe.

Conclusion

The 12% pipe cap is a vital component in the world of piping systems, contributing to the functionality, safety, and efficiency of various applications. Understanding its design and applications helps professionals make informed choices regarding piping solutions. Whether used in oil and gas, water treatment, or chemical processing, the 12% pipe cap plays a significant role in maintaining the integrity of piping systems while ensuring compliance with safety standards. As industries evolve and new challenges emerge, the importance of reliable components like the 12% pipe cap will undoubtedly continue to grow.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025