Mobile:+86-311-808-126-83

Email:info@ydcastings.com

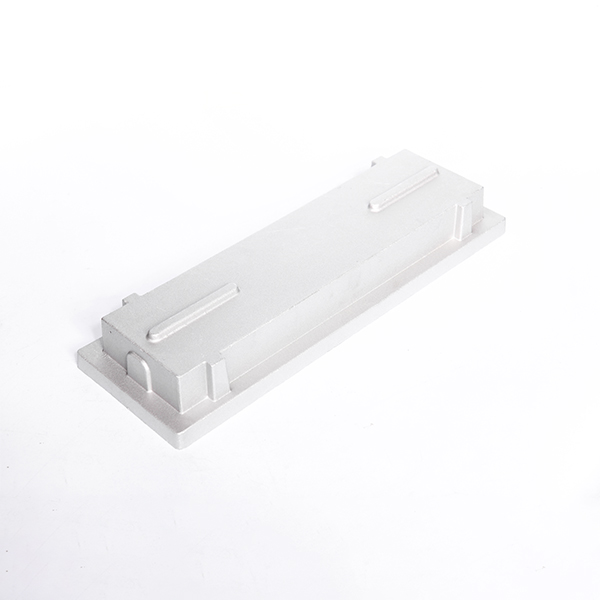

end caps for aluminum tubing

End Caps for Aluminum Tubing A Comprehensive Guide

Aluminum tubing is a versatile material that is widely used across various industries. From construction and manufacturing to DIY projects, aluminum tubing provides excellent strength-to-weight ratios, resistance to corrosion, and durability. One often-overlooked accessory that enhances the utility of aluminum tubing is end caps. These small yet essential components can significantly affect the functionality, appearance, and lifespan of the tubing. In this article, we will explore the different types of end caps available, their benefits, and their applications.

What Are End Caps?

End caps are fittings designed to cover or seal the ends of aluminum tubing. They provide a clean finish, preventing the ingress of moisture, dirt, and contaminants. Additionally, end caps can improve safety by eliminating sharp edges, which might pose a risk of injury. They come in various shapes, sizes, and materials, specifically designed to fit different tubing diameters and applications.

Types of End Caps

1. Plastic End Caps These are the most common type of end caps used for aluminum tubing. They are lightweight, resistant to corrosion, and affordable. Plastic end caps are easy to install, making them ideal for both industrial and DIY projects. They also come in a range of colors, offering aesthetic options for finishing projects.

2. Rubber End Caps Rubber caps provide a flexible sealing option, offering superior impact resistance compared to plastic. They are particularly useful in applications where the tubing may experience vibrations or movement, as they can absorb shocks and prevent damage to the ends of the tubing.

3. Metal End Caps For heavy-duty applications, metal end caps are the best choice. These caps are often made of aluminum or stainless steel and provide enhanced durability and strength. They are ideal for applications that require additional structural integrity or need to withstand extreme environmental conditions.

4. Threaded End Caps For applications requiring secure sealing or pressure resistance, threaded end caps can be used. These caps screw onto the ends of the tubing, ensuring a tight fit and preventing leakage. This design is common in plumbing, HVAC, and other industrial applications.

Benefits of Using End Caps

end caps for aluminum tubing

1. Protection from Elements One of the primary functions of end caps is to protect the insides of the aluminum tubing from dust, dirt, moisture, and other contaminants. This protection is crucial for maintaining the integrity and performance of the tubing, especially in outdoor or industrial environments.

2. Enhanced Safety Sharp edges at the ends of aluminum tubing can lead to injuries. End caps cover these edges, making the tubing safer to handle. This is especially important in settings where the tubing is manipulated frequently or where it is in close proximity to workers.

3. Aesthetic Appeal With a variety of colors and finishes available, end caps can enhance the appearance of aluminum tubing. For projects that are visible to the public, such as furniture or architectural installations, choosing the right end cap can lead to a more polished and professional look.

4. Increased Longevity By protecting the ends of the tubing from environmental factors and physical damage, end caps can extend the lifespan of aluminum tubing. This can save costs in the long run, reducing the need for repairs or replacements.

Applications of End Caps

End caps for aluminum tubing have numerous applications across diverse sectors

- Construction In building and construction, end caps are used to cover the ends of aluminum guardrails and railings, ensuring safety and stability. - Furniture Design Many furniture pieces utilize aluminum tubing, with end caps providing a modern, finished look. - Agriculture End caps protect irrigation tubing and fittings, preventing clogging and leaks that can disrupt water flow. - Automotive and Aerospace End caps are essential in the automotive and aerospace industries for sealing fuel lines, air ducts, and other critical components.

Conclusion

In conclusion, end caps play a critical role in maximizing the performance and lifespan of aluminum tubing. They offer protection from the elements, enhance safety, improve aesthetics, and extend the duration of the tubing's functionality. Whether you're involved in industrial projects, construction, or creative DIY endeavors, selecting the right end caps can make a significant difference in your project's success. With a variety of types and materials available, there is an ideal end cap for every application, making them a worthy investment for any aluminum tubing project.

-

Impeller Technology That Powers Precision in Pump SystemsNewsMay.22,2025

-

Valve Durability Begins with Quality Cast Iron ComponentsNewsMay.22,2025

-

Performance Cooling with Advanced Automobile Water Pump SolutionsNewsMay.22,2025

-

How Motor Housing and Oil Pans Shape Engine PerformanceNewsMay.22,2025

-

How Metal Castings Drive Modern Manufacturing EfficiencyNewsMay.22,2025

-

Exploring the Engineering Behind Valve Body CastingsNewsMay.22,2025