Mobile:+86-311-808-126-83

Email:info@ydcastings.com

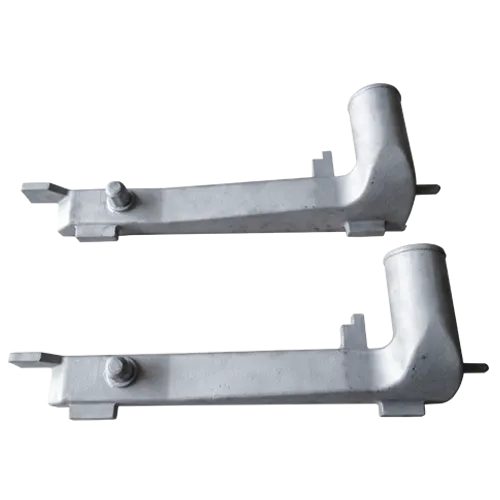

efr turbine housing

The Significance of EFR Turbine Housing in Modern Engineering

In the realm of modern engineering, particularly in the field of aerospace and automotive industries, the efficiency and performance of engines have become paramount. One of the critical components that often remains unnoticed but plays a vital role in this domain is the Enhanced Factory Racing (EFR) turbine housing. This component is integral to the overall functionality of turbochargers, which are essential for improving engine performance.

The primary purpose of a turbine housing in a turbocharger system is to house the turbine wheel and direct the exhaust gases effectively to spin the turbine. In the case of EFR turbine housing, the design is tailored to optimize the performance characteristics of the turbocharger. Unlike traditional turbine housings, EFR models utilize advanced materials and innovative engineering techniques to enhance velocity, reduce turbo lag, and improve responsiveness.

The Significance of EFR Turbine Housing in Modern Engineering

Another vital aspect of EFR turbine housing is its versatile design, which allows for various configurations to accommodate different engine types and performance requirements. This adaptability makes EFR turbine housings suitable for a wide range of applications, from high-performance racing cars to everyday vehicles seeking enhanced power output. This flexibility extends to mating with different turbine wheel sizes, which can ultimately refine the boost characteristics and throttle response of the engine.

efr turbine housing

A core advantage of the EFR turbine housing design is its integrated wastegate system. The wastegate controls the flow of exhaust gases to the turbine, thereby regulating boost pressure and optimizing performance. The integration of this system within the turbine housing simplifies installation and contributes to a more compact engine layout. This not only saves space but also ensures that the system responds swiftly to changes in engine load, minimizing turbo lag and enhancing drivability.

Moreover, EFR turbine housing typically features advanced computational fluid dynamics (CFD) designs. These designs optimize the flow of exhaust gases, reducing turbulence and promoting smoother airflow through the turbine. Consequently, this leads to an increase in efficiency, allowing the turbocharger to generate more power with less engine strain. In competitive racing scenarios, where every ounce of power counts, the advantages of such innovations can materially impact race outcomes.

Environmental concerns are also driving the evolution of turbine housing design. As manufacturers strive to meet increasingly stringent emissions regulations, turbochargers equipped with EFR turbine housings can achieve better fuel economy and lower emissions. By enabling engines to operate more efficiently at various RPMs, these turbine housings help manufacturers develop vehicles that meet green standards without compromising performance.

In conclusion, EFR turbine housing represents a fusion of innovative design and engineering excellence that significantly enhances engine performance across various applications. Its lightweight, adaptable, and efficient construction not only improves the functionality of turbochargers but also aligns with modern demands for both power and environmental responsibility. As the automotive and aerospace industries continue to evolve, the significance of components such as the EFR turbine housing will only grow, paving the way for the next generation of high-performance, efficient engines. Those engaged in automotive enhancements, racing, or any performance-oriented modifications would do well to consider the benefits offered by EFR turbine housings in their pursuit of excellence.