Mobile:+86-311-808-126-83

Email:info@ydcastings.com

drummond 1 10 hp transfer pump impeller

The Drummond 1-2010 HP Transfer Pump Impeller An Overview

In the world of fluid dynamics and pumping systems, the efficiency and reliability of pumps play a crucial role in various industrial and commercial applications. One such critical component is the impeller, particularly in the Drummond 1-2010 HP transfer pump. This article aims to provide an overview of the Drummond 1-2010 HP transfer pump impeller, its design, functionality, and significance in modern pumping technology.

Understanding the Basics

The impeller is a rotating component of a pump designed to impart energy to the fluid. It works by converting rotational energy from the pump's motor into kinetic energy, causing the fluid to flow. In the case of the Drummond 1-2010 HP transfer pump, the impeller is engineered for optimal performance, balancing efficiency and durability.

Design Features

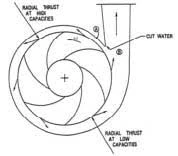

The design of the Drummond 1-2010 HP impeller reflects advanced engineering principles. This centrifugal pump impeller typically consists of several vanes that are strategically engineered to maximize fluid flow while minimizing energy loss. The materials used in its construction are critical for enhancing its resistance to wear and corrosive environments, ensuring longevity and reliability.

One distinguishing feature of the Drummond impeller is its ability to maintain a high flow rate while operating at various pressures. This adaptability makes it suitable for a range of applications, from agriculture to industrial water transfer. Furthermore, the design often incorporates features that allow for easy maintenance and replacement, reducing downtime for operations.

Functionality

When the Drummond 1-2010 HP transfer pump is activated, the motor drives the impeller, causing it to spin rapidly. As the impeller rotates, it creates a low-pressure area at its center, drawing fluid into the pump from the inlet. The unique geometry of the vanes accelerates the fluid outward, increasing its velocity before discharging it at the pump's outlet.

drummond 1 10 hp transfer pump impeller

The efficiency of the impeller directly affects the overall performance of the pump. A well-designed impeller minimizes turbulence and cavitation, enabling smoother fluid flow. Additionally, it factors significantly into the pump's energy consumption, making it an essential component for operators interested in reducing operational costs.

Importance in Applications

The Drummond 1-2010 HP transfer pump impeller is not just a mechanical part; it plays a vital role in several applications. From irrigation systems to industrial processes, effective fluid transfer is essential. The impeller's capability to handle different types of fluids—including those with solid particles—highlights its versatility.

In industries such as mining, construction, and wastewater management, where robust and reliable fluid transfer systems are needed, the Drummond impeller's performance is crucial. It can handle high volumes, ensuring that operations run smoothly and efficiently.

Maintenance and Longevity

To maximize the service life of the Drummond 1-2010 HP transfer pump impeller, regular maintenance is essential. Operators should monitor for signs of wear, such as corrosion or physical damage to the impeller blades. Routine inspections can prevent unexpected failures and costly downtime.

Parts replacement, when necessary, should be done using genuine Drummond components to maintain compatibility and performance consistency. Investing in a quality impeller can pay off in terms of reduced energy costs and increased pump lifespan.

Conclusion

The Drummond 1-2010 HP transfer pump impeller stands as a testament to effective engineering and design in fluid management systems. With its ability to deliver high flow rates under varying pressures, it serves a multitude of applications across different industries. Understanding its design and functionality is vital for operators seeking to enhance their pumping systems' efficiency and reliability. As technology continues to advance, innovations in impeller designs will undoubtedly shape the future of fluid transfer, making efficient pumps like the Drummond 1-2010 HP invaluable assets in the modern industrial landscape.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025