Mobile:+86-311-808-126-83

Email:info@ydcastings.com

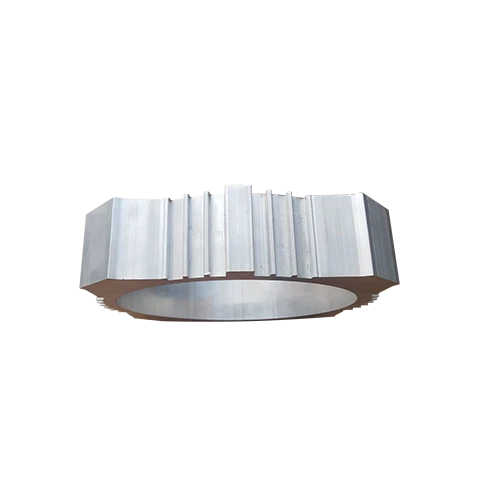

double entry impeller

Understanding the Double Entry Impeller A Key Component in Fluid Dynamics

The double entry impeller is an innovative design commonly used in various pumping applications, particularly in centrifugal pumps. Unlike traditional single entry impellers, the double entry version offers distinct advantages in efficiency and performance, making it a preferred choice for many industrial and engineering applications.

One of the primary characteristics of a double entry impeller is its symmetrical design. This type of impeller is open on both sides, allowing fluid to enter from both the front and rear. This not only facilitates an even distribution of fluid pressure but also enhances the overall hydraulic balance within the pump. As a result, the double entry impeller significantly reduces wear and tear on the pump components, extending the lifespan of the equipment.

The performance benefits of using a double entry impeller are evident in applications requiring high flow rates and pressures

. The dual entry design allows for a more robust flow, enabling the pump to handle greater volumes without compromising efficiency. This is particularly beneficial in sectors such as water treatment, chemical processing, and HVAC systems, where consistent and reliable fluid transport is crucial.double entry impeller

Another notable advantage of the double entry impeller is its ability to operate at higher efficiencies compared to single entry designs. By allowing fluid to enter from two sides, the impeller achieves better hydraulic performance, resulting in lower energy consumption. This is increasingly important as industries strive to meet sustainability goals and reduce operational costs. Lower energy usage not only minimizes the environmental impact but also enhances the economic viability of pumping operations.

The versatility of double entry impellers also deserves mention. They can be configured for various applications and are adaptable to different fluid types, making them suitable for both clean and contaminated fluids. Furthermore, the design can be tailored to meet specific operational requirements, including varying pressures and temperatures, thereby improving overall system performance.

Maintenance of double entry impellers is relatively straightforward due to their balanced design, which reduces the likelihood of vibration and misalignment. This contributes to smoother operation and less frequent repairs. Regular maintenance practices can ensure that these impellers continue to perform optimally, thereby enhancing the reliability of the entire pumping system.

In conclusion, the double entry impeller is a critical component in modern fluid dynamics systems. Its design offers numerous advantages, including improved efficiency, reduced wear, and versatility across various applications. With the growing demands for enhanced performance and sustainability in industrial processes, the double entry impeller stands out as a solution that meets the challenges of contemporary fluid management.

-

Impeller Technology That Powers Precision in Pump SystemsNewsMay.22,2025

-

Valve Durability Begins with Quality Cast Iron ComponentsNewsMay.22,2025

-

Performance Cooling with Advanced Automobile Water Pump SolutionsNewsMay.22,2025

-

How Motor Housing and Oil Pans Shape Engine PerformanceNewsMay.22,2025

-

How Metal Castings Drive Modern Manufacturing EfficiencyNewsMay.22,2025

-

Exploring the Engineering Behind Valve Body CastingsNewsMay.22,2025